Inactivated germ melt-blown fabric and production process thereof

A technology for inactivating germs and melt-blown fabrics, which can be used in non-woven fabrics, melt spinning, chemical characteristics of fibers, etc., and can solve serious problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

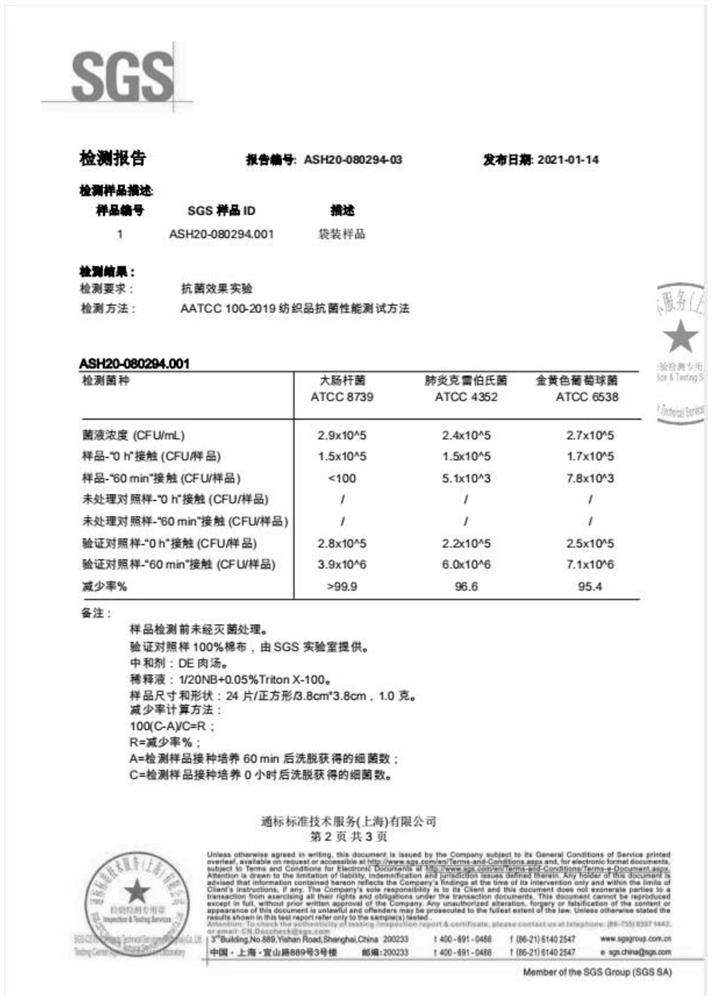

Image

Examples

Embodiment 1

[0019] Also disclosed is a production process for inactivated germ melt-blown cloth, comprising the following steps:

[0020] S1: Pre-preparation of raw materials: Prepare 75kg of polypropylene PP-1500, 2.5kg of zinc oxide and 3.5kg of cuprous oxide and put them into the mixing tank for 40 minutes and stir for later use;

[0021] S2: Melt spraying: The spare raw materials are heated and plasticized by the main screw machine, then accurately quantified by the metering pump, and then sprayed on the mesh belt receiver through the melt blown nozzle;

[0022] S3: Melt-blown cloth forming: the melt is evenly sprayed on the mesh curtain by high-temperature air pressure through the mold spinneret, and the bottom of the mesh curtain is collected and formed by a negative pressure fan;

[0023] S4: Stationed in static electricity: the formed melt-blown cloth is transported by the mesh curtain to the electrostatic electret equipment, and the electrostatic electret cabinet is used for the ...

Embodiment 2

[0028] A production process of a melt-blown cloth for inactivating germs, comprising the following steps:

[0029] S1: Pre-preparation of raw materials: prepare 115kg of polypropylene PP-1500, 7.5kg of zinc oxide and 9.5kg of cuprous oxide and put them into the mixing tank and stir for 80 minutes for standby;

[0030] S2: Melt spraying: The spare raw materials are heated and plasticized by the main screw machine, then accurately quantified by the metering pump, and then sprayed on the mesh belt receiver through the melt blown nozzle;

[0031] S3: Melt-blown cloth forming: the melt is evenly sprayed on the mesh curtain by high-temperature air pressure through the mold spinneret, and the bottom of the mesh curtain is collected and formed by a negative pressure fan;

[0032] S4: Stationed in static electricity: the formed melt-blown cloth is transported by the mesh curtain to the electrostatic electret equipment, and the electrostatic electret cabinet is used for the electret pro...

Embodiment 3

[0037] A production process of a melt-blown cloth for inactivating germs, comprising the following steps:

[0038] S1: Pre-preparation of raw materials: Prepare 95kg of polypropylene PP-1500, 5kg of zinc oxide and 7kg of cuprous oxide and put them into the mixing tank and stir for 60 minutes for standby;

[0039] S2: Melt spraying: The spare raw materials are heated and plasticized by the main screw machine, then accurately quantified by the metering pump, and then sprayed on the mesh belt receiver through the melt blown nozzle;

[0040] S3: Melt-blown cloth forming: the melt is evenly sprayed on the mesh curtain by high-temperature air pressure through the mold spinneret, and the bottom of the mesh curtain is collected and formed by a negative pressure fan;

[0041] S4: Stationed in static electricity: the formed melt-blown cloth is transported by the mesh curtain to the electrostatic electret equipment, and the electrostatic electret cabinet is used for the electret process;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com