Repairing process for water leakage of parapet wall

A parapet and water leakage technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of laborious and low construction efficiency, and achieve the effect of improving the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

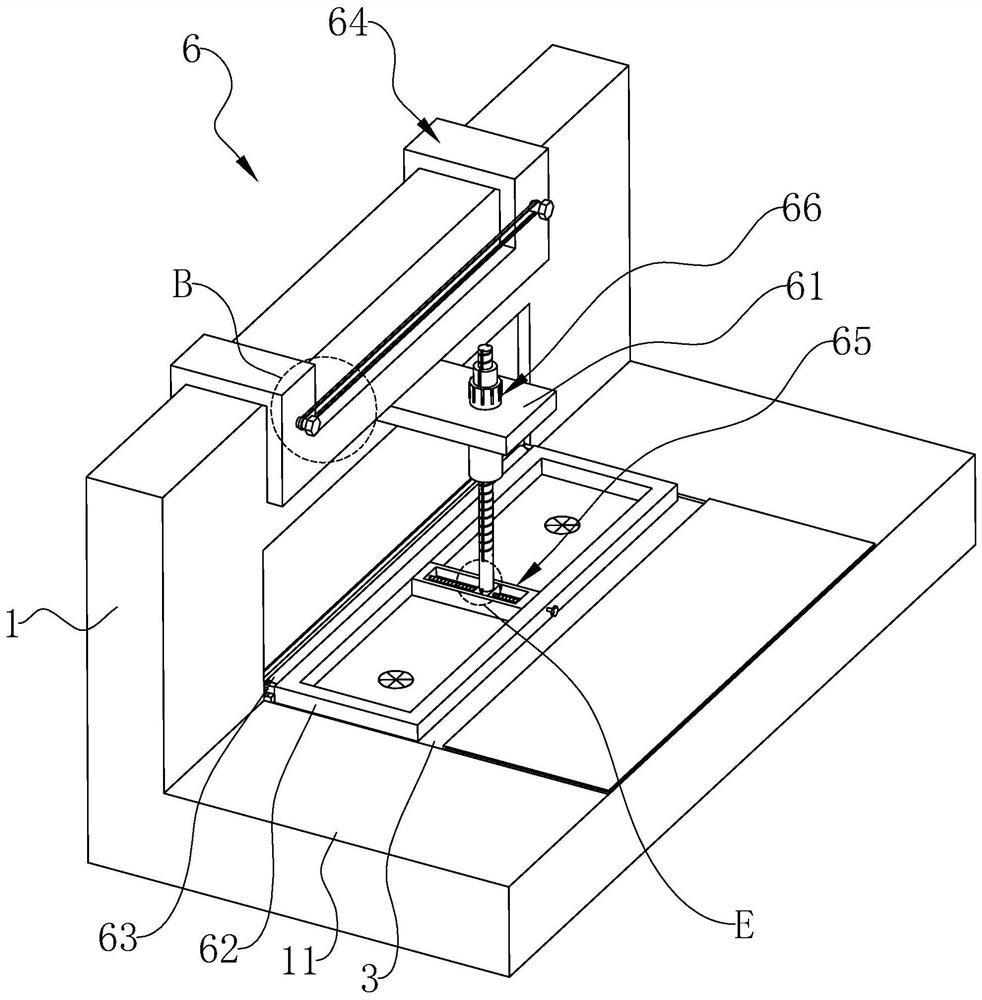

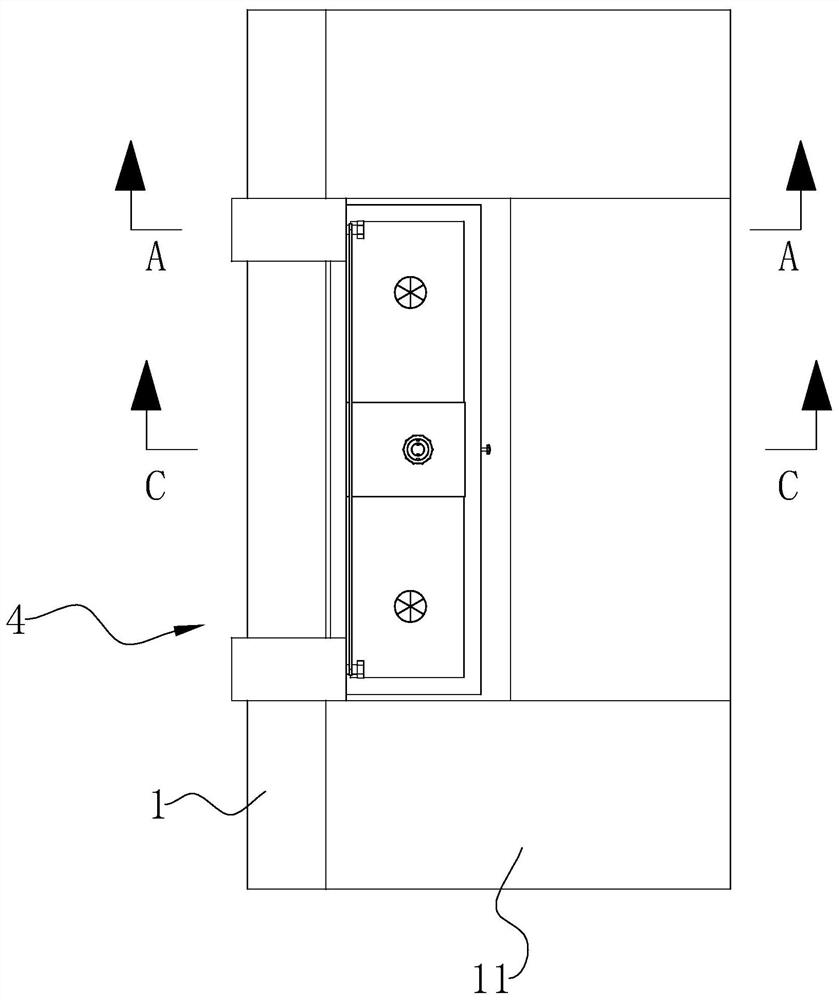

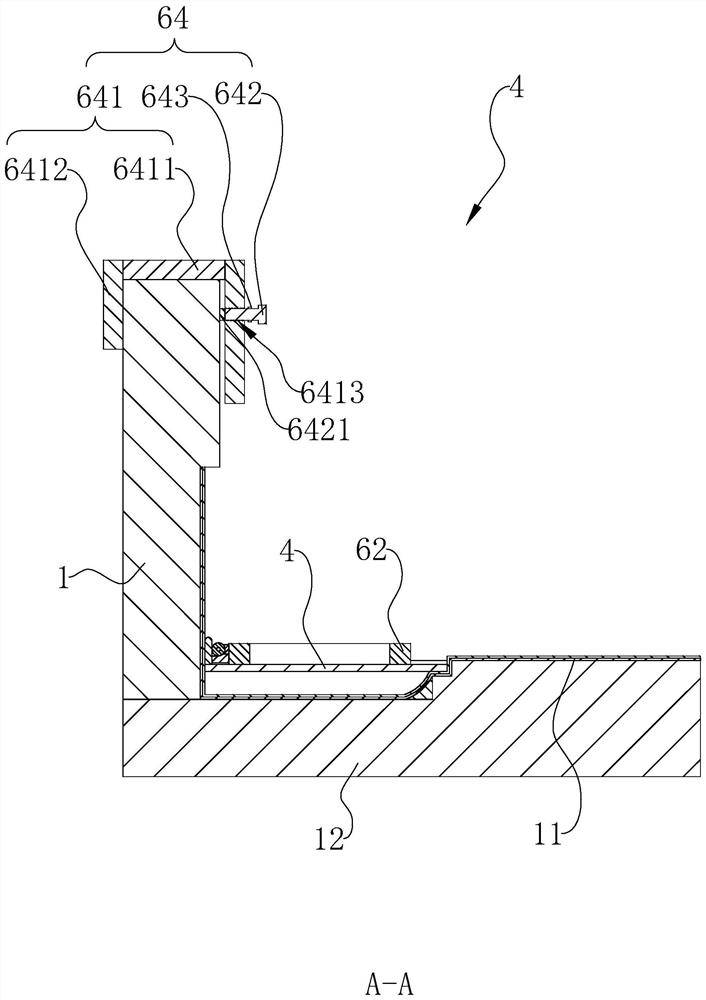

[0044] The following is attached Figure 1-9 The application is described in further detail.

[0045] The embodiment of the present application discloses a holding device for repairing water seepage in a parapet wall.

[0046] Such as figure 1 and figure 2 As shown, a holding device for parapet water leakage repair process mainly includes a bracket 61, a pressing frame 62, a pressing roller 63, a fixing part 64, a pressing part 65 and a pressing part 66, the fixing part 64 and the pressing part 66 The top of the support 61 is connected, and the fixing member 64 can fix the support 61 on the installation base; the compression frame 62 is slid and arranged on the support 61 along the vertical direction, the compression frame 62 is a square frame, and the compression component 66 is also provided On the support 61, the pressing member 66 can drive the pressing frame 62 to move in the vertical direction, so that the pressing frame 62 can be pressed down on the object to be pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com