Field Density Relay Calibration Device and Calibration Method

A density relay and calibration device technology, which is applied to measurement devices, circuit breaker testing, instruments, etc., can solve the problem that the density relay calibration device cannot flexibly change speed and commutate, and achieve convenient commutation, simple overall structure, and low price. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

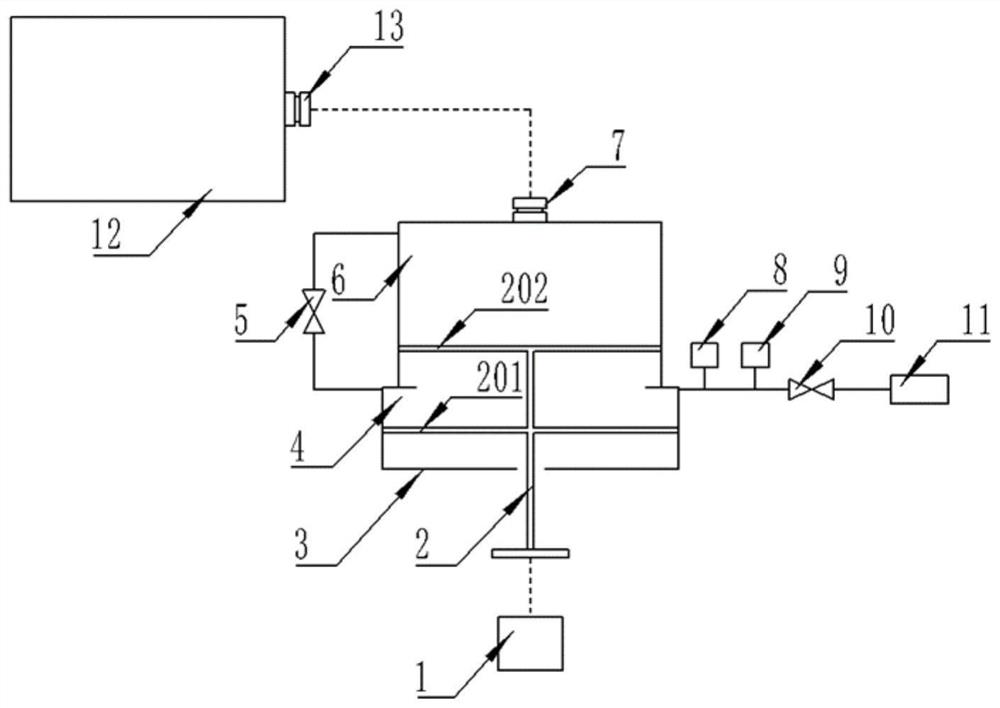

[0068] Such as figure 1 As shown, an on-site density relay calibration device includes a driving mechanism 1, a push rod 2, a first cylinder 3, a first closed space 4, a first valve 5, a second closed space 6, a first quick-plug interface 7, A temperature detection mechanism 8, a pressure detection mechanism 9, a second valve 10, an air circuit interface 11, a second cylinder 12, a second quick-plug interface 13, and a control unit.

[0069] For ease of description and understanding, the figure 1 The middle viewing angle is the main viewing angle, and the up, down, left, and right directions are used as a reference. It should be understood that the setting of the directions is only for the convenience of description and understanding, and should not be construed as a limitation of the present invention.

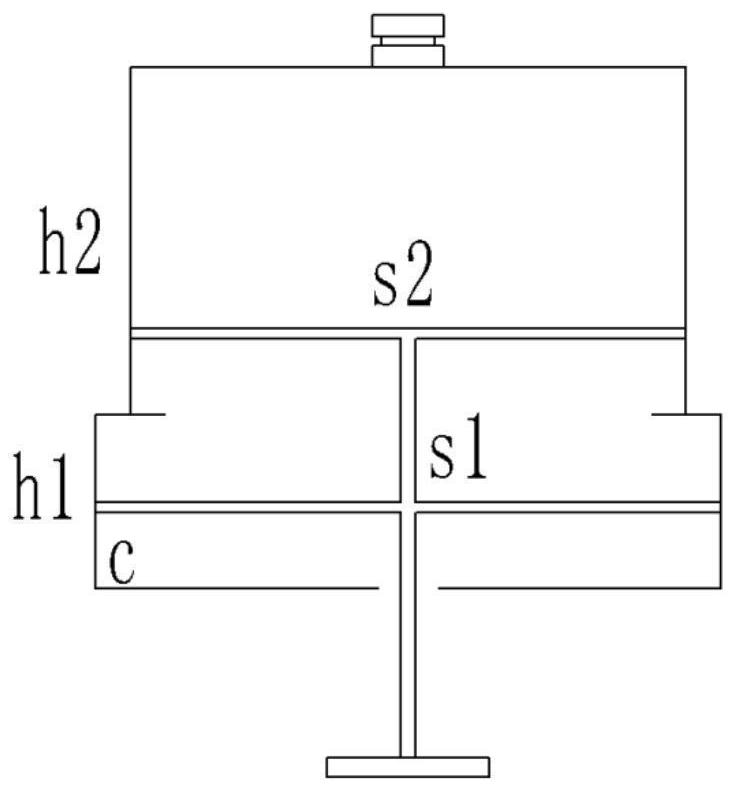

[0070] Such as figure 1 As shown, the first cylinder 3 is provided with a first cavity and a second cavity communicating with each other, and the diameters of the first cav...

Embodiment 2

[0077] The present invention also discloses a verification method using the above-mentioned on-site density relay verification device, which includes the following steps:

[0078] A. Vacuuming:

[0079] Connect the gas circuit interface 11 to the peripheral vacuum equipment, open the first valve 5 and the second valve 10, turn on the vacuum equipment, control the driving mechanism 1 to push the push rod 2, and push the first piston 201 to the first cavity 1. Discharge the remaining gas in the first cylinder 3 from the gas path interface 11 at the variable diameter of the second cavity, and close the first valve 5 and the second valve 10;

[0080] B. Degassing stage:

[0081] Close the valve between the density relay to be calibrated and the air chamber, connect the gas circuit interface 11 to the gas charging port on the side of the density relay to be calibrated, open the first valve 5 and the second valve 10, and connect the side of the density relay to be calibrated The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com