Equipment defect time prediction method based on capacitive equipment defect data

A technology for capacitive equipment and time prediction, applied in the direction of kernel methods, neural learning methods, biological neural network models, etc., can solve problems such as inconsistency, complexity, and loss of equipment parameter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

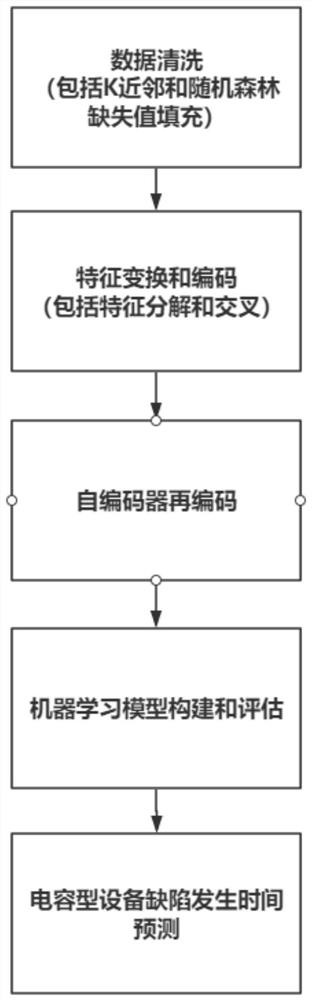

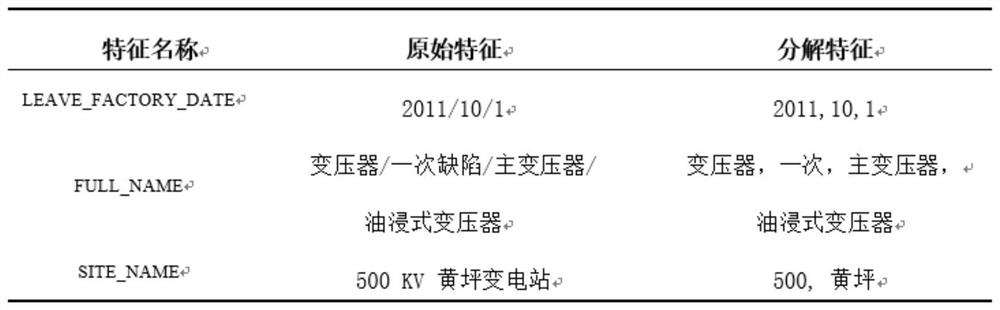

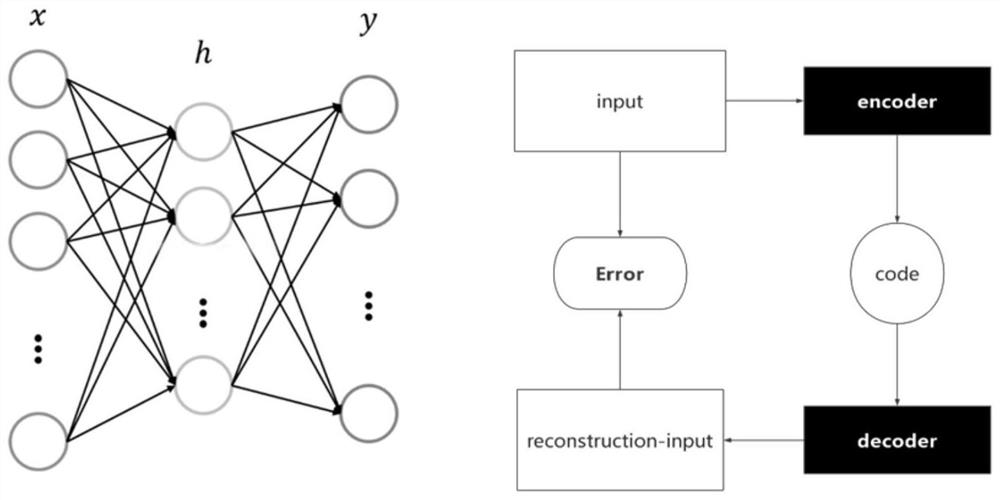

[0043] Below in conjunction with the appendix of the present invention Figure 1~4 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations can be obtained by those skilled in the art without making creative efforts.

[0044] In this implementation, please refer to figure 1 ,

[0045] S1: Perform data cleaning processing on the capacitive equipment defect data set: remove more than 70% of the missing values, and use the K nearest neighbor algorithm and random forest algorithm to fill the missing values for more than 30% of the missing values; draw each feature according to the data characteristics The box plot, and thus remove the data to remove outliers; delete all redundant data and empty data;

[0046] Firstly, the outliers of the capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com