Photoelectric and photo-thermal integrated system

A photovoltaic power generation system and photothermal technology, applied in the field of comprehensive utilization of solar energy, can solve the problems of limited cooling effect of photovoltaic panels, poor heat dissipation of materials, and insufficient heat dissipation rate, so as to improve photovoltaic power generation efficiency, photoelectric conversion rate, and comprehensive The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

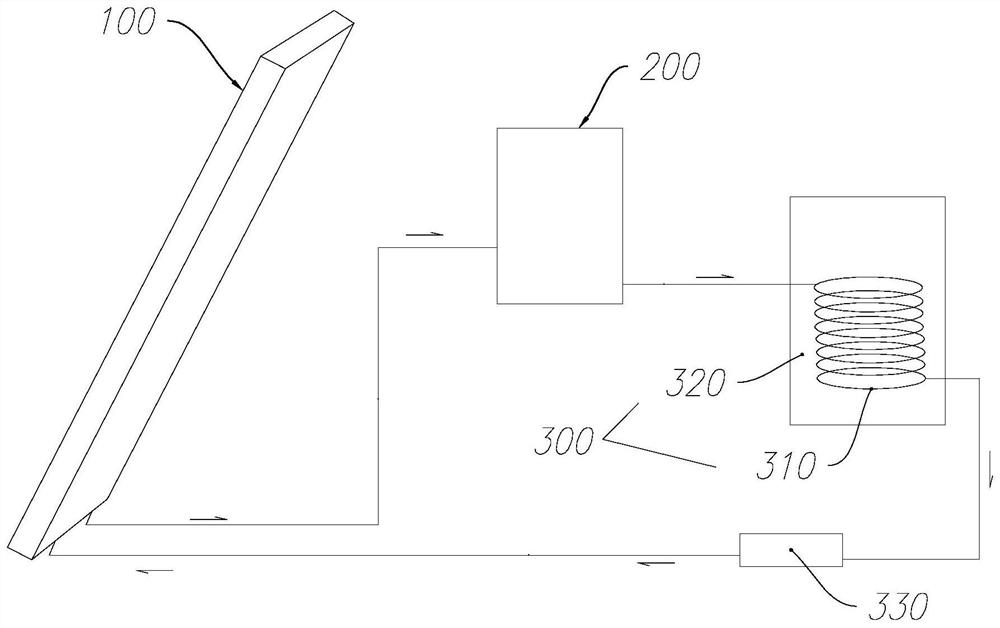

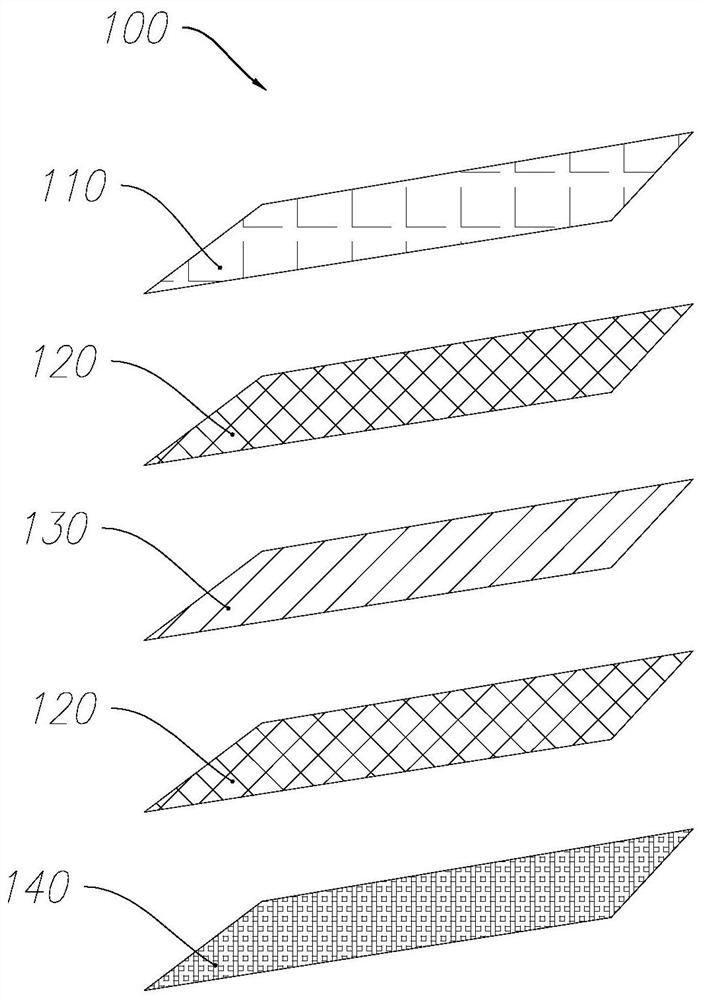

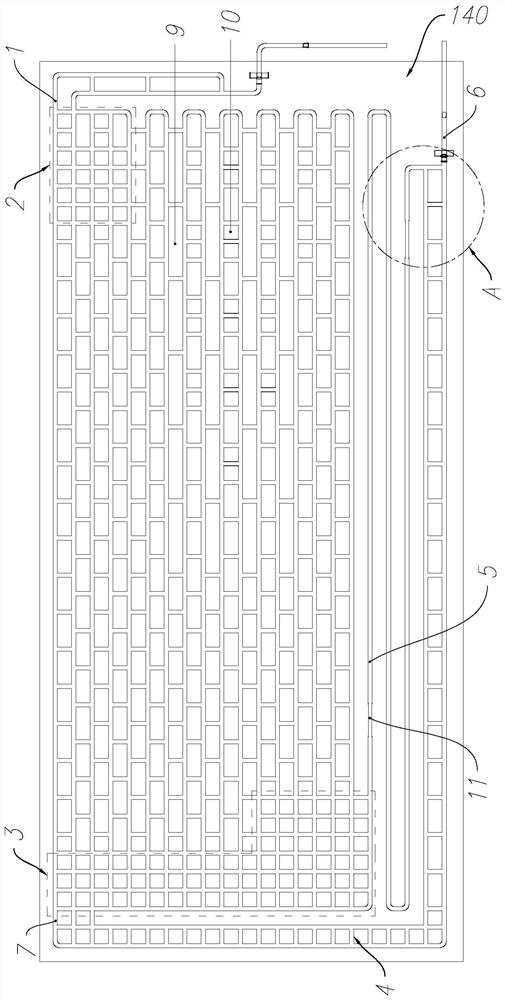

[0035] Such as figure 1 As shown, this embodiment shows a photoelectric, photothermal integrated system, the system uses such as figure 2 The photoelectric, photothermal integrated assembly shown includes tempered glass 110, transparent EVA 120, photovoltaic power generation main body 130, heat absorbing backplane 140, and an outer frame for fixing. The heat-absorbing back plate 140 is provided with a working medium flow channel for absorbing heat and cooling down the photovoltaic power generation main body 130 through the working medium in the working medium flow channel. In the working state, the temperature of the heat-absorbing backplane is generally about 10°C lower than the ambient temperature, so as to avoid the reduction of the photoelectric conversion rate caused by the temperature of the main body of photovoltaic power generation being much higher than the ambient temperature during power generation. Therefore, the photoelectric, photothermal integrated module can ...

Embodiment 2

[0050] Such as Figure 5 As shown, another embodiment of the working fluid channel is shown. The main difference between the heat-absorbing backplane 140 in Embodiment 2 and the heat-absorbing backplane 140 in Embodiment 1 is that the length of the heat-absorbing backplane 140 in this embodiment is shorter in the horizontal direction than in the vertical direction; The working medium flow channel in the evaporation area includes a horizontal flow channel and a vertical flow channel, and the cross flow channel and the vertical flow channel intersect and the intersection is in the shape of a "cross". That is, the intersection of the horizontal flow channel and the vertical flow channel divides the evaporation area into several small squares of equal area.

[0051] The evaporation area is also provided with an anti-short flow part 8 for preventing the liquid working medium in the working medium channel from directly entering the gaseous communication area 3; the short flow preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com