Refrigerant radiator, assembly design method and air conditioning equipment

A technology for refrigerant radiators and air-conditioning equipment, which is applied to lighting and heating equipment, heating methods, and electrical equipment structural components, etc., and can solve problems such as random installation positions and poor heat dissipation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

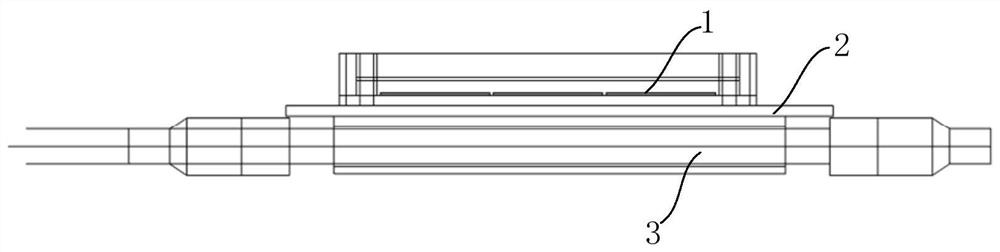

[0041] This embodiment provides a refrigerant radiator, which is applied to the heating module of the equipment. figure 1 It is a structural diagram of a refrigerant radiator according to an embodiment of the present invention, such as figure 1 As shown, the refrigerant radiator includes:

[0042] The cold plate 2 is stacked with the heating module 1 . A groove is provided on the surface of the cold plate 2 away from the heating module 1 to accommodate the refrigerant pipe 3 ; the refrigerant pipe 3 is embedded in the groove of the cold plate 2 .

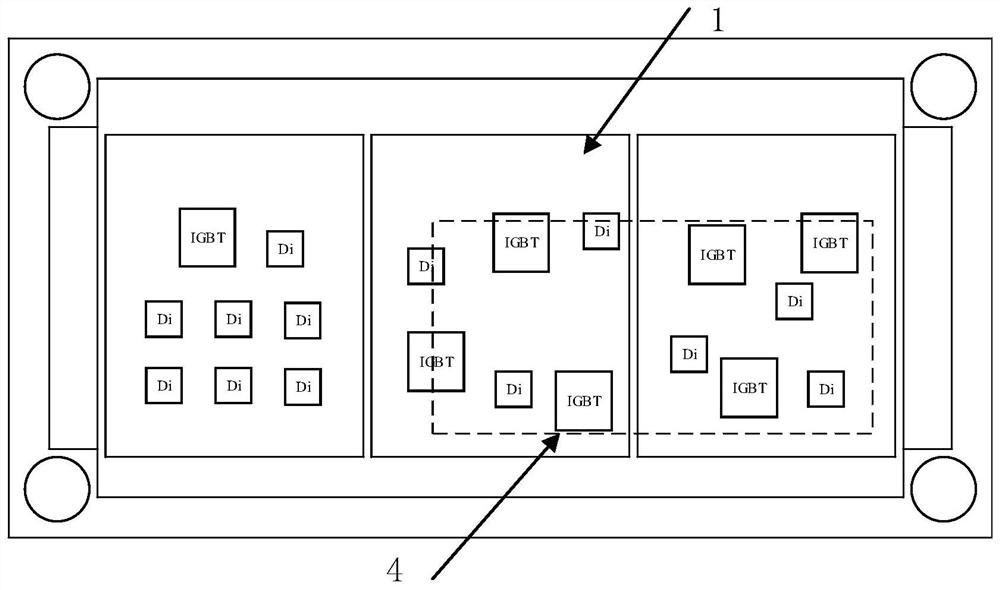

[0043] figure 2 It is a schematic diagram of the main heating area of the heating module according to the embodiment of the present invention, such as figure 2 As shown, the distribution positions of the heating chips in the heating module 1 are not regular, and are unevenly distributed along the length direction of the heating module 1. On the whole, the main heating area 4 is mainly located in a certain concentrated area of ...

Embodiment 2

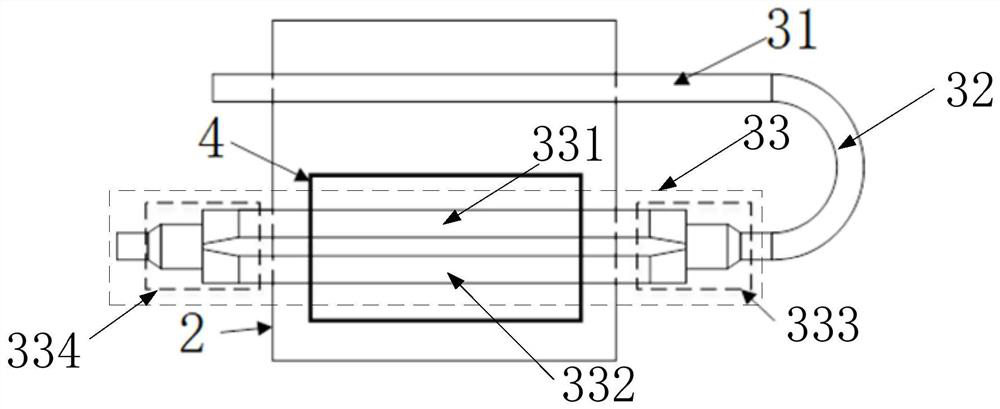

[0047] This embodiment provides another refrigerant radiator, which is applied to the heating module of the equipment. The heating module 1 is the frequency conversion module of the air conditioner. When the power or voltage of the heating module increases, the heating power will increase synchronously, so it needs to be replaced Efficient refrigerant cooling measures.

[0048] as mentioned above image 3As shown in , the inflow section 31 is located in other areas outside the main heating area 4 of the frequency conversion module (ie, the heating module 1 in the above embodiment), and the bending section 32 is located in the environment outside the frequency conversion module. The refrigerant driving system drives the refrigerant to enter the inflow section 31 and enter the outflow section through the bending section 32. Through calculation and simulation, it is found that the chips with higher heating power on the frequency conversion module are distributed in the positions ...

Embodiment 3

[0054] This embodiment provides an air conditioner, which includes a heating module, and also includes the refrigerant radiator in the above embodiment, which is used to improve the heat exchange effect, further improve the heat dissipation efficiency, ensure the heat dissipation performance of the heating module, and improve the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com