Preparation technology of constant-temperature fermented ham sauce

A technology of constant temperature fermentation and preparation technology, applied in the direction of food science, etc., can solve the problems of poor taste and flavor, not strong enough aroma of ham sauce, etc., to achieve the effect of easy absorption, increase nutritional value and flavor, and enhance fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

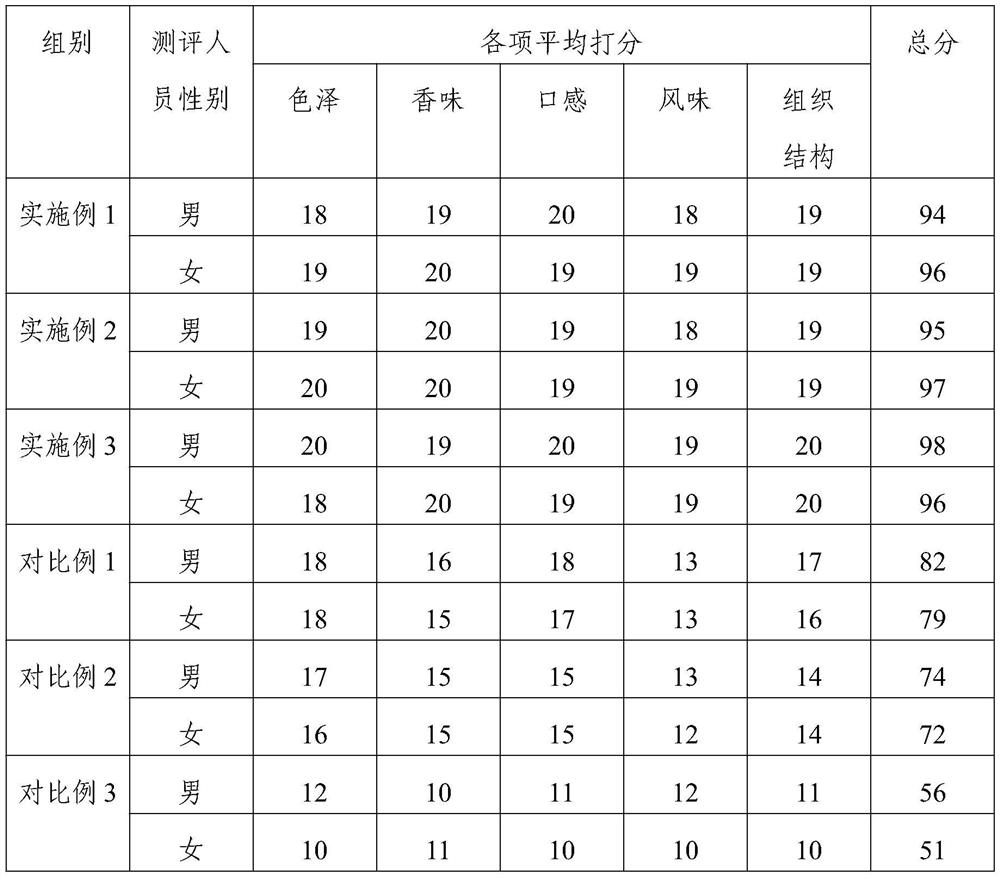

Embodiment 1

[0028] A kind of preparation technology of constant temperature fermented ham sauce, the preparation technology of described constant temperature fermentation ham sauce comprises the following steps:

[0029] (1) Ham fermentation: Cut the raw ham into slices with a thickness of 0.3cm, put them in a clean and sealed container, add lactic acid bacteria and Monascus, and ferment for 1 day at a constant temperature of 28°C. Obtain fermented ham slices for later use, wherein the mass ratio of ham, lactic acid bacteria and Monascus is 1:0.03:0.01;

[0030] (2) Cooking of ham: put the ham slices in the above step (1) in a steam pot at a steam temperature of 100°C, steam for 10 minutes, then take out and cut into diced ham, and let it cool for later use;

[0031] (3) Preparation of ingredients: add pure water to the pot, pour the shrimps, carrots, shiitake mushrooms, fungus and soybeans into the pot after the water boils, cook until they are half mature, then take them out and cut the...

Embodiment 2

[0036] A kind of preparation technology of constant temperature fermented ham sauce, the preparation technology of described constant temperature fermentation ham sauce comprises the following steps:

[0037] (1) Ham fermentation: Cut raw ham into slices with a thickness of 0.5cm, then put them in a clean and sealed container, add lactic acid bacteria and Monascus, and then place them in a constant temperature environment of 35°C to ferment for 2 days. Obtain fermented ham slices for later use, wherein the mass ratio of ham, lactic acid bacteria and Monascus is 1:0.05:0.02;

[0038] (2) Cooking of ham: put the ham slices in the above step (1) in a steam pot with a steam temperature of 120°C, steam for 15 minutes, then take out and cut into diced ham, and let it cool for later use;

[0039] (3) Preparation of ingredients: add pure water to the pot, pour the shrimps, carrots, shiitake mushrooms, fungus and soybeans into the pot after the water boils, cook until they are half mat...

Embodiment 3

[0044] A kind of preparation technology of constant temperature fermented ham sauce, the preparation technology of described constant temperature fermentation ham sauce comprises the following steps:

[0045] (1) Ham fermentation: Cut raw ham into slices with a thickness of 0.4cm, put them in a clean and sealed container, add lactic acid bacteria and Monascus, and ferment for 1.5 days at a constant temperature of 31.5°C. Obtain fermented ham slices for later use, wherein the mass ratio of ham, lactic acid bacteria and Monascus is 1:0.04:0.015;

[0046] (2) Cooking of ham: put the ham slices in the above step (1) in a steam pot with a steam temperature of 110°C, steam for 12.5 minutes, then take out and cut into diced ham, and let it cool for later use;

[0047](3) Preparation of ingredients: add pure water to the pot, pour the shrimps, carrots, shiitake mushrooms, fungus and soybeans into the pot after the water boils, cook until they are half mature, then take them out and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com