Disposable diaper with pearl granular interlayer

A granular, interlayer paper technology, applied in bandages, medical science, absorbent pads, etc., can solve problems such as uneven urine diffusion, water absorption and coagulation of the core layer, skin eczema, etc., to promote and improve blood circulation and increase penetration speed , Improve the effect of capillary action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

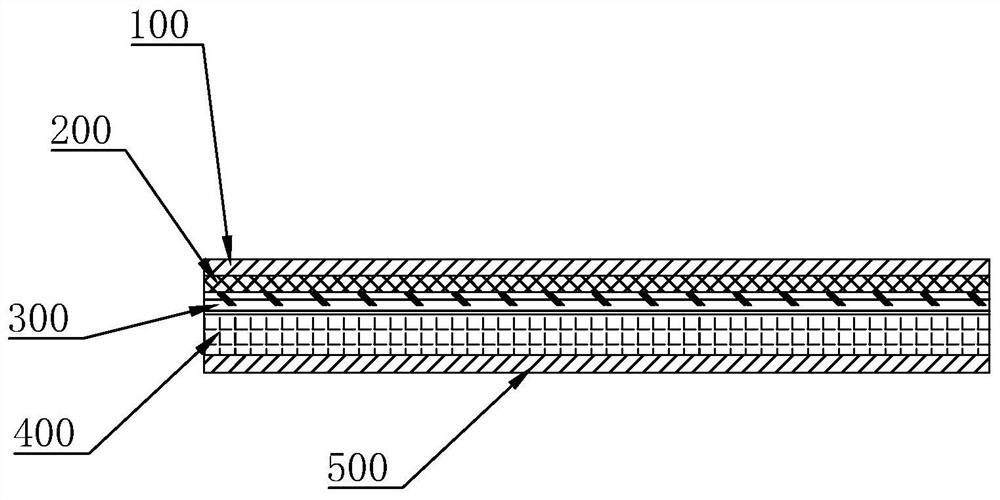

[0032] Such as figure 1 As shown, the paper diaper with pearl granular interlayer of the present invention includes a surface layer 100, a flow diversion layer 200, an absorbent core layer 400 and a bottom film layer 500 from top to bottom, and also includes a reverse osmosis layer 300, which is located on the between the flow diversion layer 200 and the absorbent core layer 400;

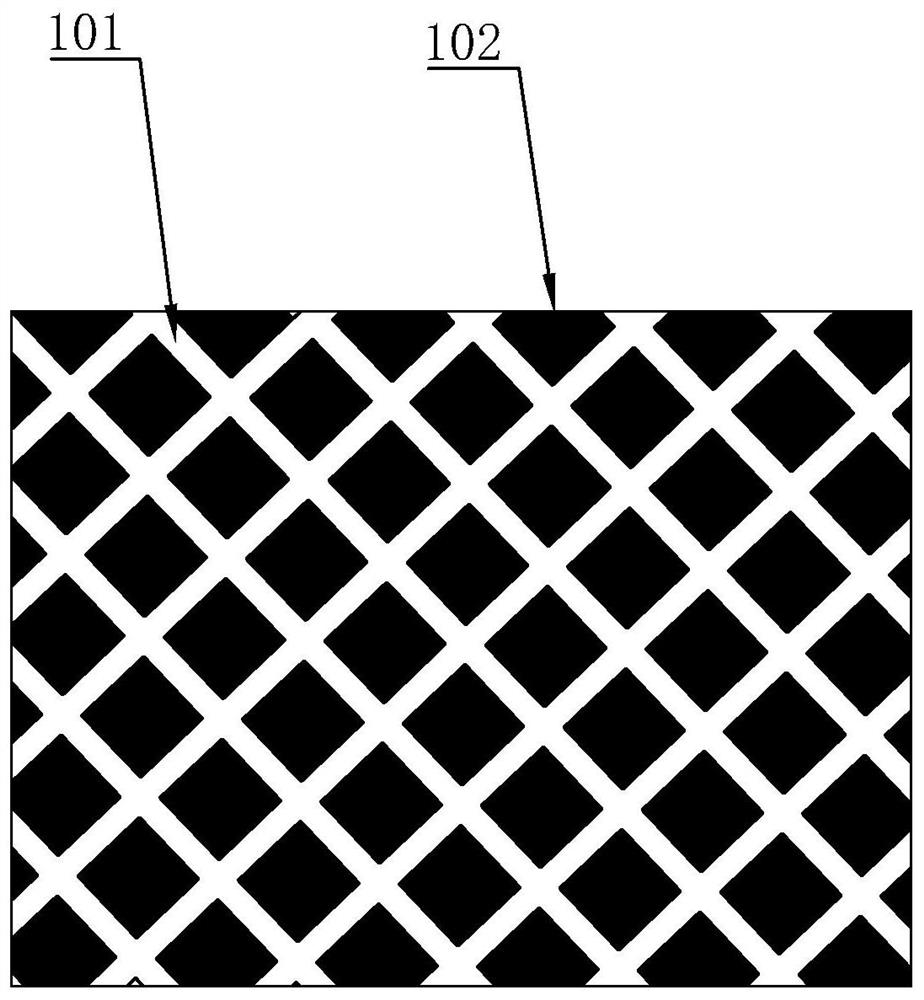

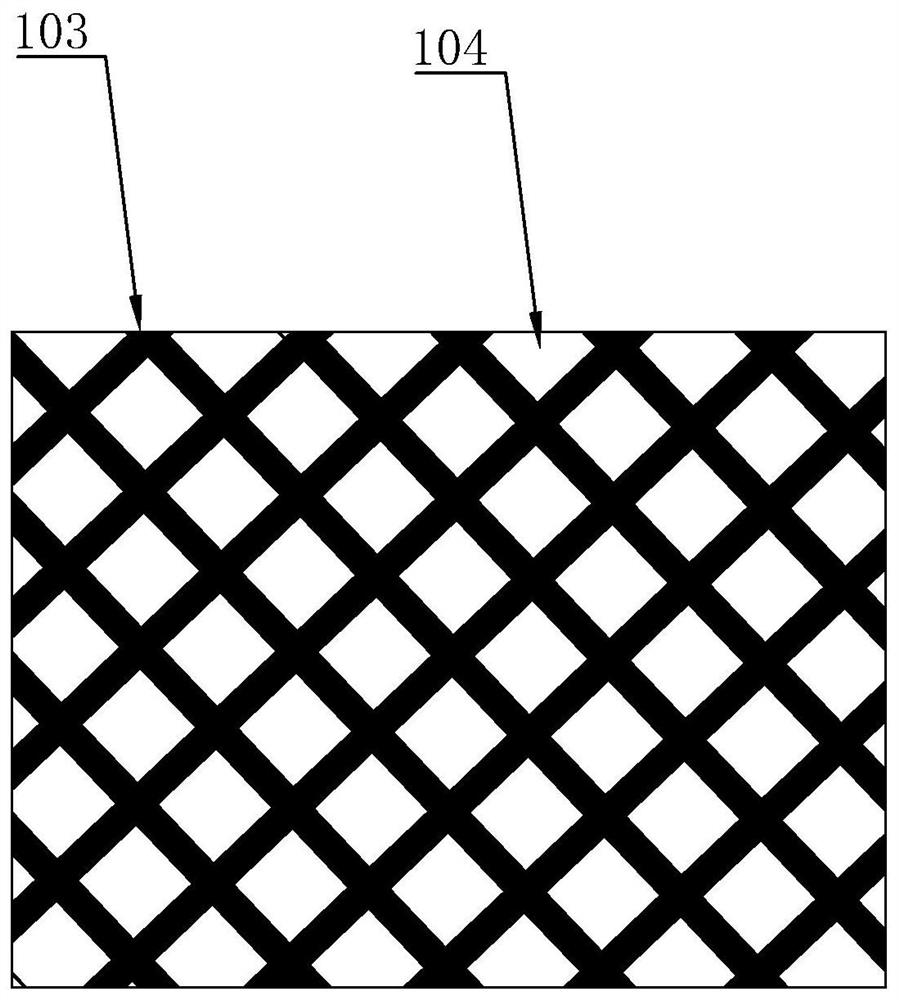

[0033] Such as figure 2 and 3 As shown, the front of the surface layer 100 is provided with diamond-shaped grid concave lines 101 and diamond-shaped raised particles 102, and the back side of the surface layer 100 is provided with diamond-shaped grid convex lines 103 and dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com