Automatic backwashing filter and working method

A backwashing and filter technology, applied in chemical instruments and methods, fixed filter element filters, separation methods, etc., can solve the problems of insufficient sewage treatment capacity, small filtering area, slow liquid flow, etc., and achieve convenient replacement and filtration. High efficiency and the effect of increasing filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the application will be further described below in conjunction with the accompanying drawings:

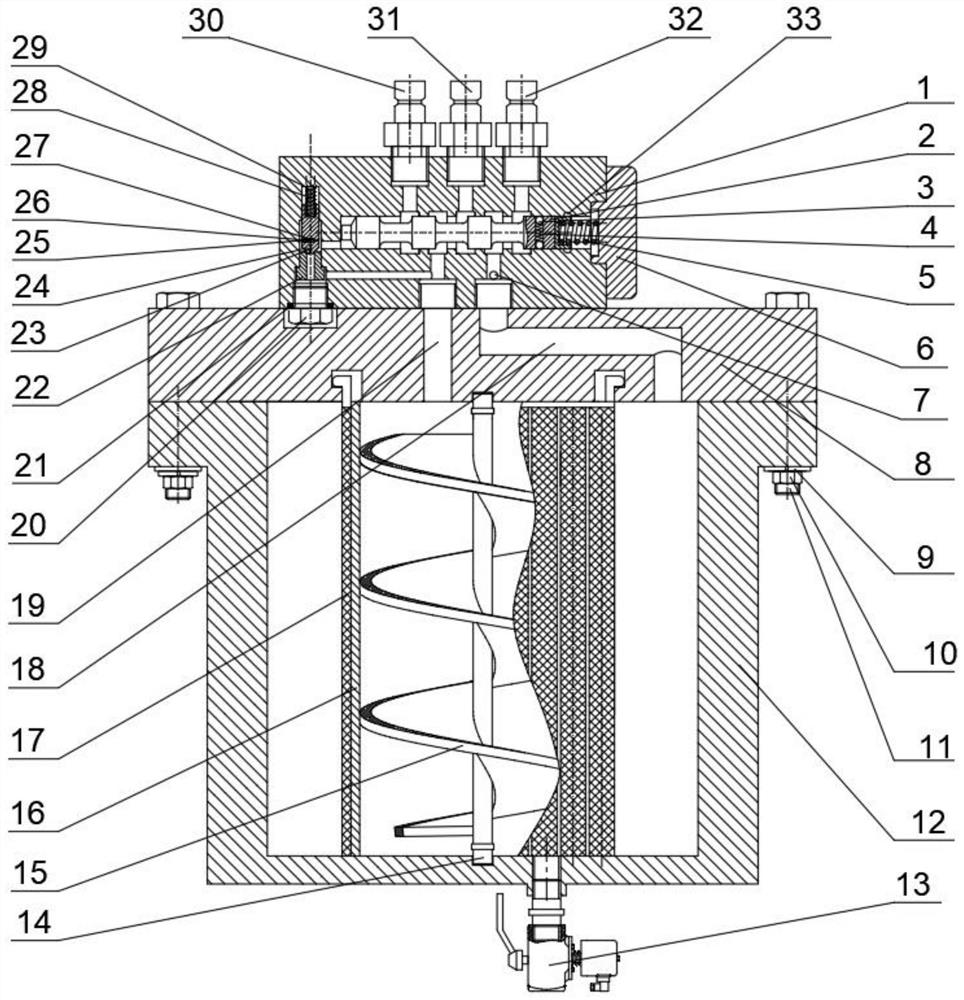

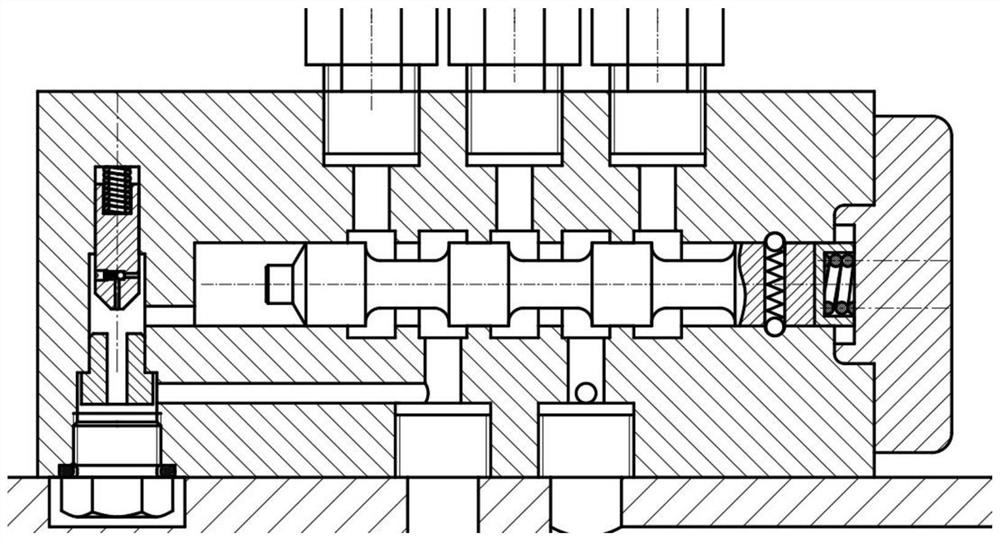

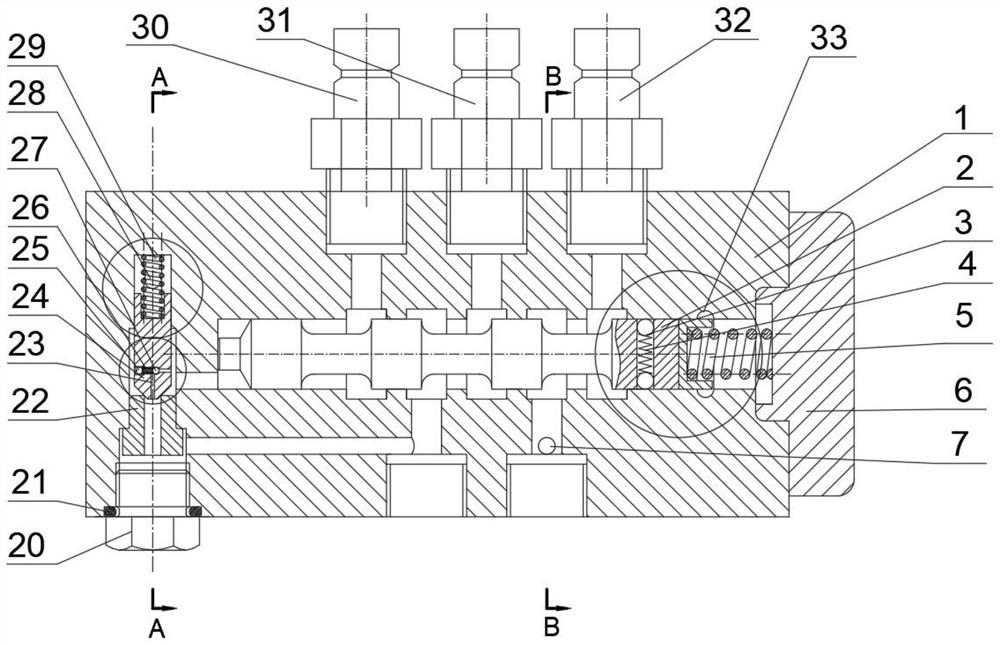

[0045] Such as figure 1 and 3 As shown, the automatic backwash filter of the present invention includes a channel switching main valve, a valve plate 8 and a cylinder 12, wherein the valve plate 8 is arranged on the upper opening of the cylinder 12, and the main valve is arranged on the valve plate 8 and Conduction with the inside of the cylinder body 12 through the flow channel; the valve plate 8 and the cylinder body 12 are connected by bolts (11), gaskets (9) and nuts (10);

[0046] Wherein cylinder body 12 is provided with the filter screen 16 of columnar structure by filter screen steel frame 17, and filter screen 16 is arranged in the filter screen steel frame 17, and cylinder body 12 inner space is divided into two spaces by filter screen 16, wherein filter The space in the screen 16 is provided with a spiral blade 15 for scraping the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com