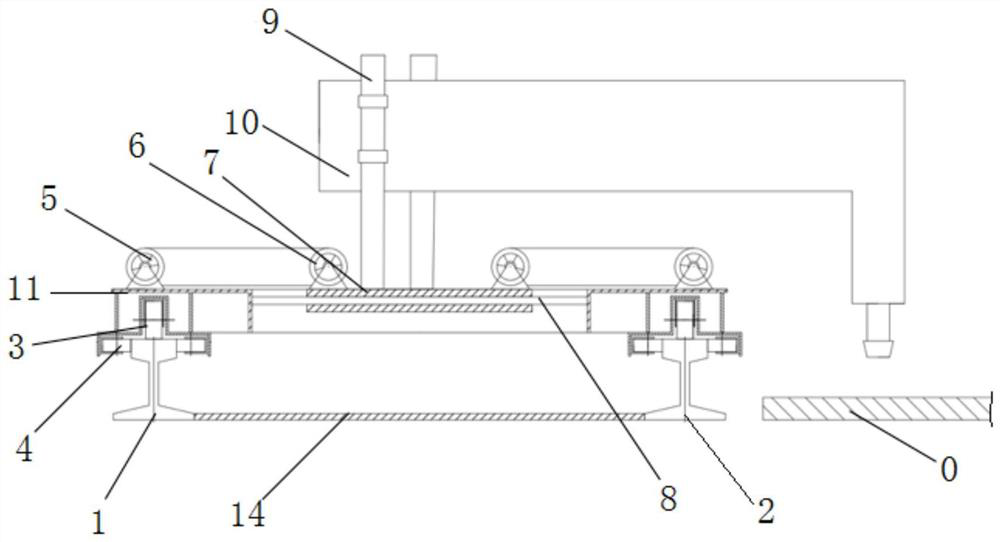

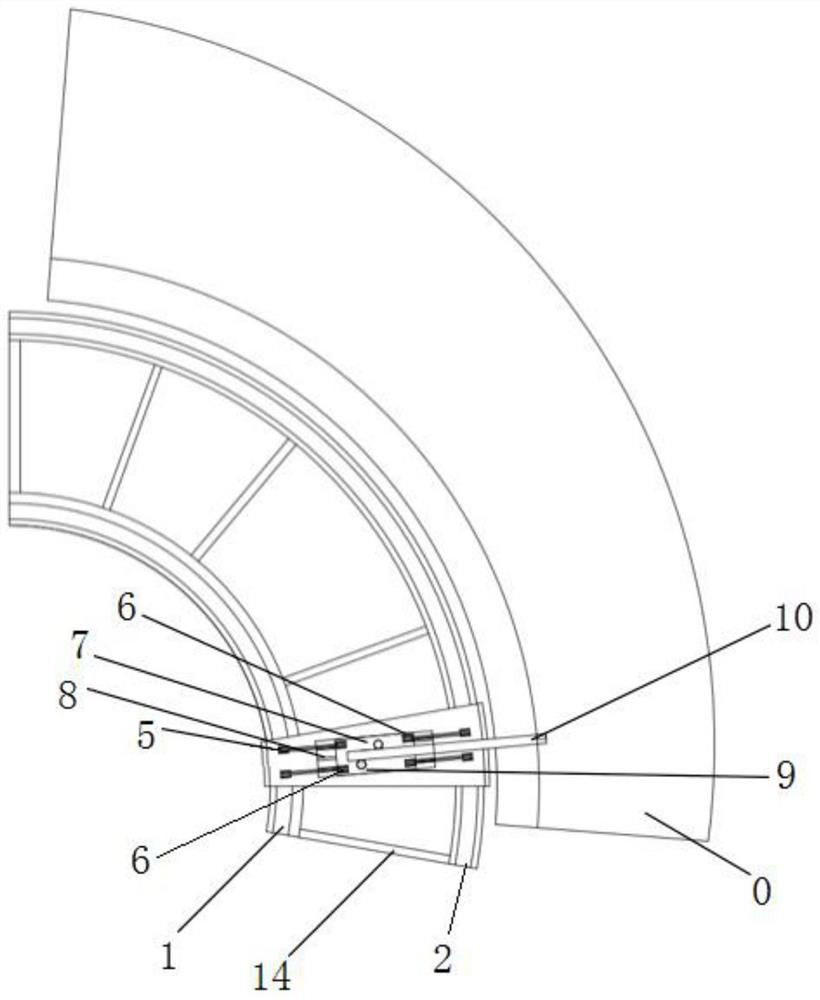

Tool for guiding welding machine heads to move in arc direction through double rails

A double-track, machine head technology, applied to the device supporting the electrode clamp, manufacturing tools, welding rod characteristics, etc., can solve the problems of large heat input per unit length, large deformation, and long construction period, so as to reduce post-weld deformation , Reduce welding heat input and increase manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

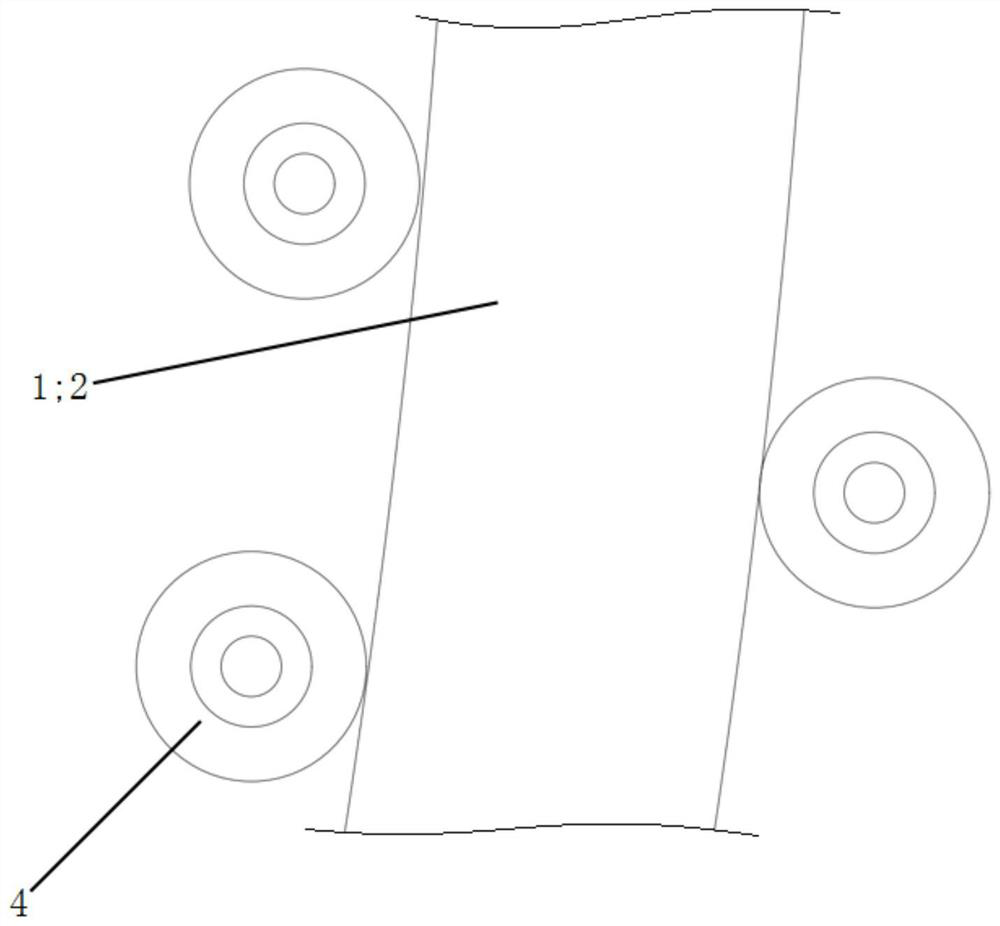

[0019] see Figure 1 to Figure 5 As shown, the tooling of the present invention that uses double tracks to guide the arc movement of the welding machine head includes a double track assembly 1; 2, a rubber guide wheel set 3; 4, an arc vertical travel wheel set 5; 6, an arc vertical travel Island 7; 8, welding machine head 9; 10, structural middle plate 11 and motor unit 12; 13, the motor unit respectively controls rubber guide wheel group 3; 4 and arc vertical travel wheel group 5; 6. The double track assembly 1; 2 includes the inner arc track 1 and the outer arc track 2, and the stroke island 7 in the vertical direction of the arc; 8 bridges between the inner arc track 1 and the outer arc track 2 through the structural middle plate 11, and the arc vertical direction The stroke island 7; 8 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com