Cutting surface rust prevention device for wired glass

A technology of wired glass and cutting surface, which is applied to the surface coating liquid device, grinding/polishing safety device, grinding machine, etc. It can solve the problems of wire mesh sealing, wire mesh and air oxidation and rust, etc., to achieve The effect of preventing recontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

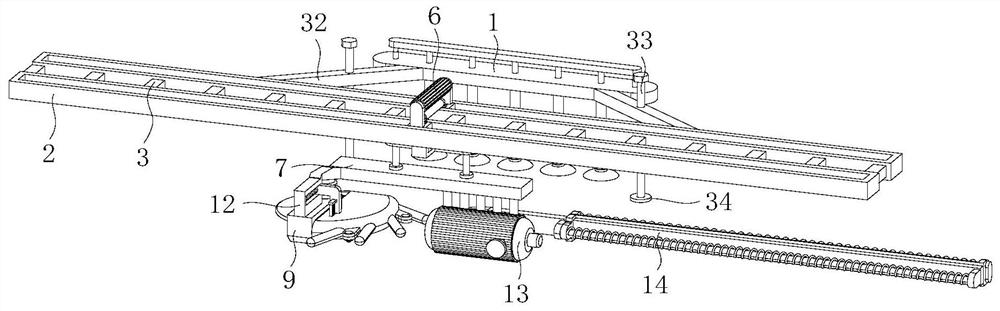

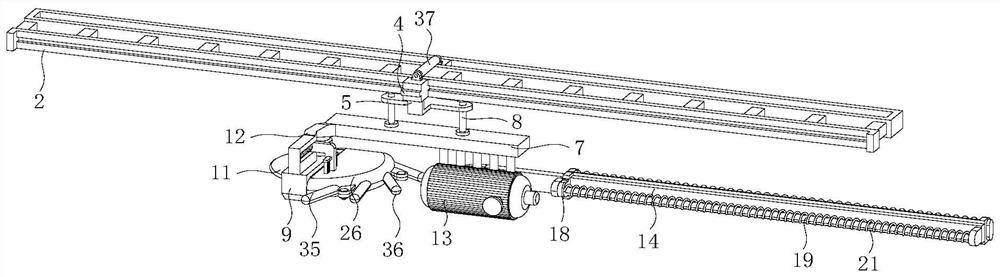

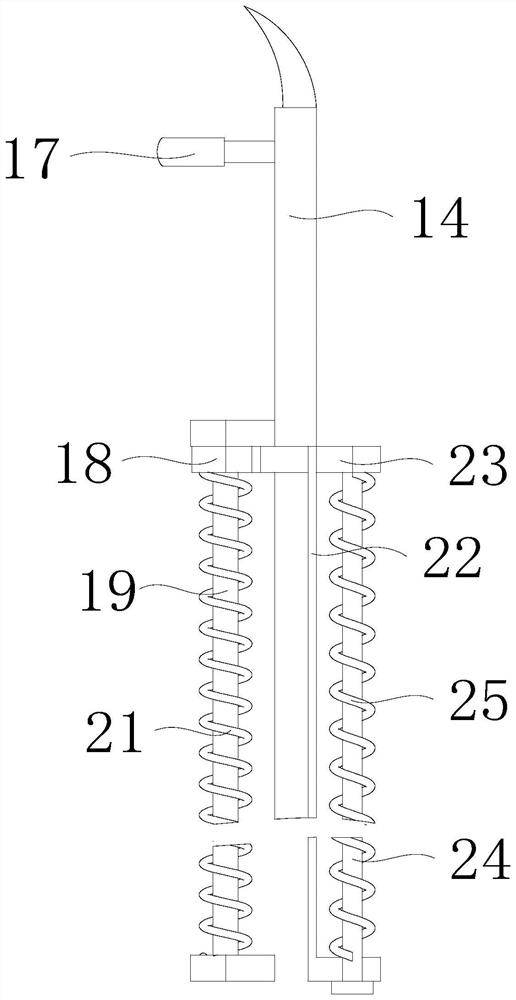

[0026] Such as Figure 1-6 As shown, a cutting surface antirust device for wired glass includes a support plate 1 and a limit frame 2, the number of limit frames 2 is two, and the two limit frames 2 are located in front of the support plate 1, and the limit frame 2 located at the rear The frame 2 and the support plate 1 are fixedly connected by two connecting plates 32, the upper surface of the connecting plate 32 is fixedly threaded with a stabilizing bolt 33, the bottom surface of the stabilizing bolt 33 is fixedly connected with a cushion 34, and the stabilizing bolt 33 elevating device is fixed on the glass. The stability when together prevents the device from tilting.

[0027] The two limiting frames 2 are fixedly connected by several short rods 3, and the insides of the two limiting frames 2 are slidably inserted with sliders 4, and the bottom surfaces of the two sliders 4 are fixedly connected by a support frame 5. The upper surface is fixedly connected by the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com