Air energy heat insulation external combustion power system and travelling crane driving method

A power system and drive method technology, applied in the field of vehicles, can solve the problems of short cruising range, large volume, and undeveloped air energy engines, and achieve the effect of reducing the use of fuel and fuel, and improving combustion and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

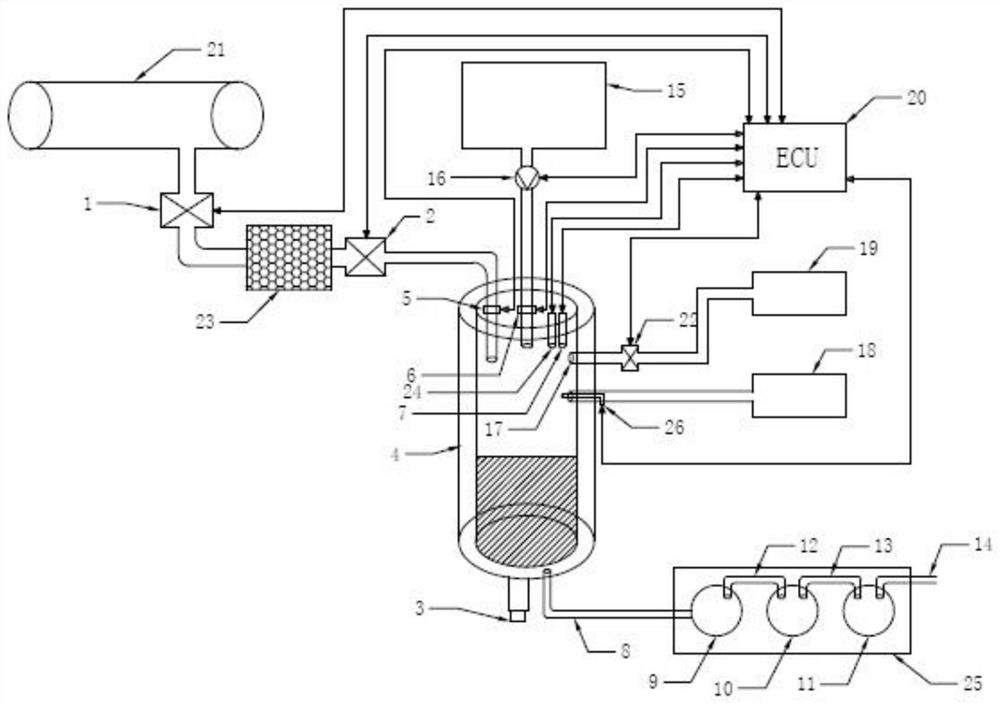

[0044] figure 1 A schematic structural block diagram of an air energy adiabatic external combustion power system according to an embodiment of the present invention is shown. Such as figure 1 As shown, the air energy adiabatic external combustion power system includes an adiabatic combustion chamber 4 and a crank linkage mechanism 25 communicating with the adiabatic combustion chamber 4 . Among them, the compressed air and fuel are selectively injected into the adiabatic combustion chamber 4, the fuel is injected into the adiabatic combustion chamber 4 and combusted to generate high-pressure mixed gas, and the crank-link mechanism 25 is used to transform the pressure energy of the high-pressure compressed air or the high-pressure mixed gas It is mechanical energy, which realizes external work. It can be understood that when the compressed air is injected into the combustion chamber, it directly passes through the combustion chamber and enters the crank linkage mechanism 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com