Automatic image correction system based on scanning

An automatic correction, image technology, applied in the conveyor control device, conveyor objects, object supply and other directions, can solve problems such as downtime, scanning image tilt, equipment paper jams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

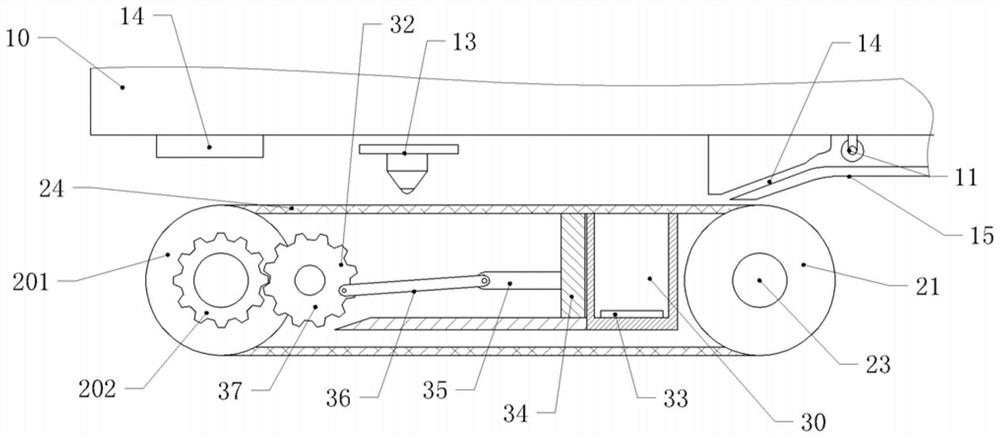

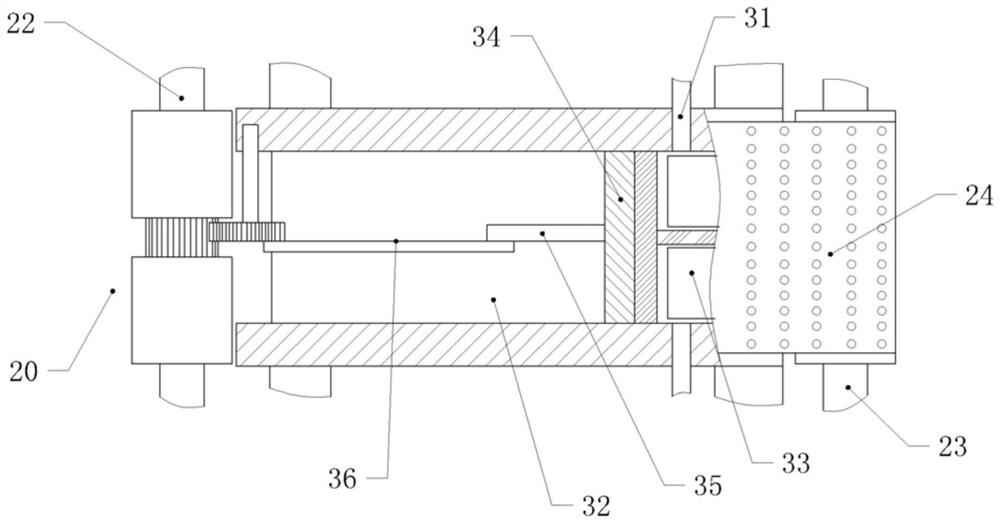

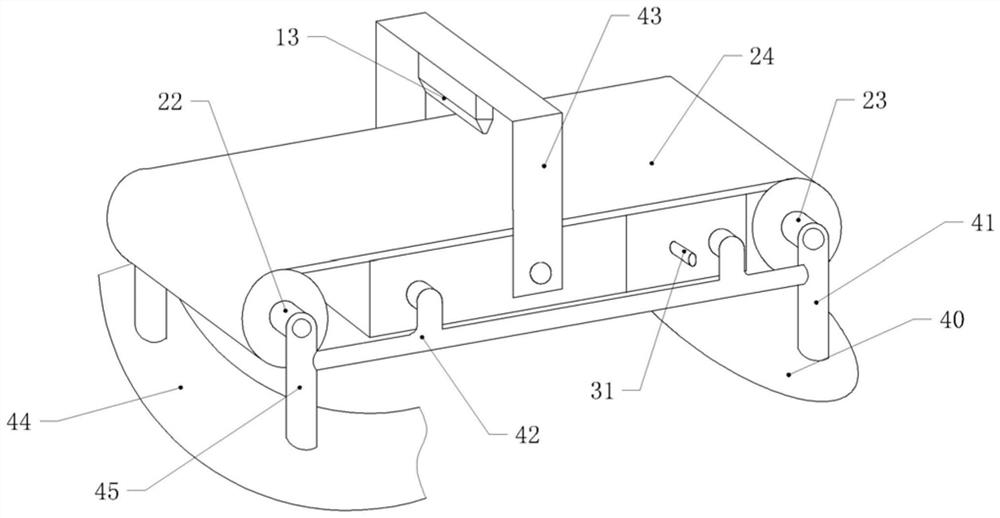

[0020] The reference numerals in the drawings of the description include: frame 10, paper feed wheel 11, paper feed channel 12, scanner 13, controller 14, horizontal platform 15, first rotating wheel 20, cylinder section 201, gear section 202 , the second rotating wheel 21, the first rotating shaft 22, the second rotating shaft 23, the conveyor belt 24, the negative pressure chamber 30, the air pipe 31, the sliding chamber 32, the pressure sensor 33, the slider 34, the swing lever 35, the connecting rod 36, the driving wheel 37. Turntable 40, first support bar 41, second support bar 42, support 43, slide rail 44, slide rail bar 45.

[0021] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0022] A scan-based automatic image correction system includes a frame 10, a controller 14, a paper feeding mechanism and a scanning mechanism, and the scanning mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com