Chassis cross lifting type overhead working truck with adjustable platform angle

A high-altitude operation vehicle, adjustable technology, applied in the direction of the lifting device, etc., can solve the problems of inability to meet the flexibility requirements of the aerial operation vehicle, the inability to adjust the adaptability of the working platform, and the adjustment method is not flexible enough, so as to improve the operation efficiency and walk stably , Improve the effect of driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

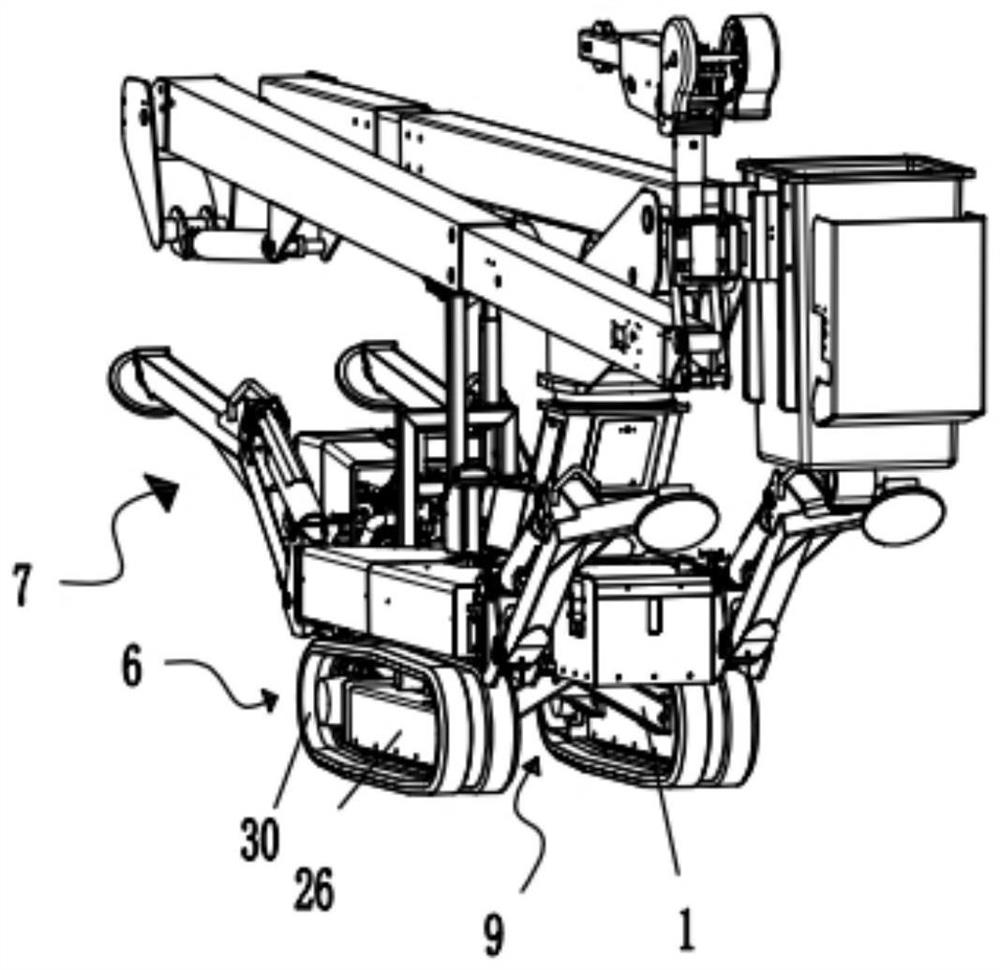

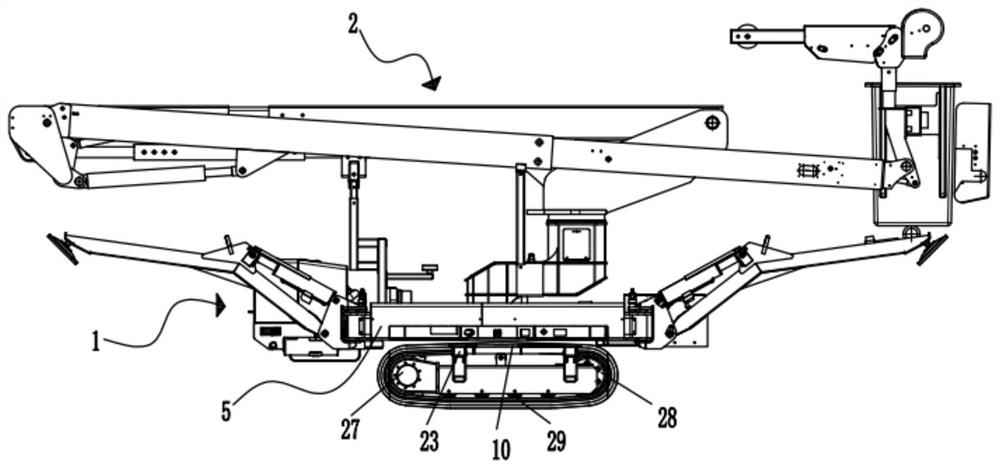

[0046] Such as Figure 1-17 As shown, a chassis cross-lifting aerial work vehicle with an adjustable platform angle includes a vehicle frame 1, a carrier frame arranged on the frame, and a column, a turret, a lower arm, a A shaft joint, an upper arm, a telescopic arm, and a working bucket are connected in sequence to form a top 2, and the top is a device for working at heights. The top of the upper arm 4 of the bodywork is provided with an overall angle adjustment device for adjusting the position of the work bucket of the bodywork connected by a connecting mechanism. The connected load-bearing end, and the adjustment end for adjusting the overall angle of the working bucket; the vehicle frame includes a load-carrying frame 5 for installing the upper body, two parallel running gears 6 for moving, and for connecting the load-carrying frame and The cross-type extended lifting device 7 of the traveling mechanism, the cross-type extended lifting device includes a support mechanis...

Embodiment 2

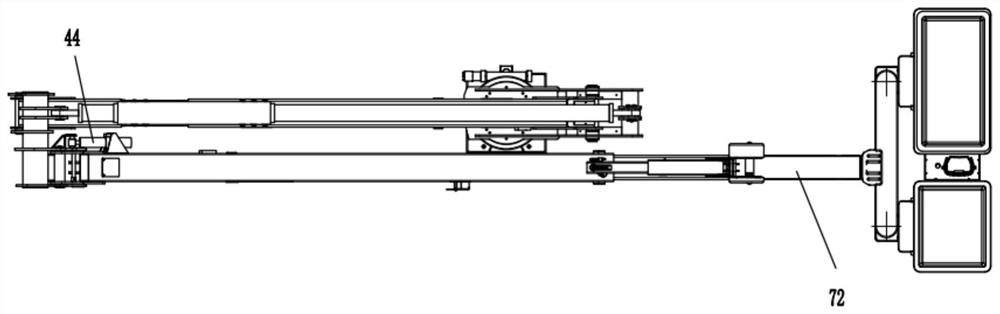

[0071] The same parts of this embodiment and Embodiment 1 will not be described again. The difference is that a crank arm 70 connected by a connecting mechanism for adjusting the position of the working bucket of the top is provided on the top of the upper arm of the top. The crank includes A supporting device 71 for connecting with the upper arm, a small crank arm 72 for connecting the working bucket, and a crank arm rotation mechanism 73 for connecting the supporting device and the small crank arm.

[0072] The connection mechanism includes a telescopic arm that is provided with an insulating section and a non-insulating section through a telescopic oil cylinder that cooperates with the upper arm. The supporting device includes a T-shaped support seat 74, and the lower end of the support seat is connected to the upper side of the front end of the telescopic arm through a pin shaft. It also includes one end connected below the front end of the T-shaped support base, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com