A method for returning rice straws to the field after fast rot

A technology of returning rice stalks to the field, which is applied in the preparation of organic fertilizers, fertilizers made from biological waste, agriculture, etc., can solve the problems of slow rice stalks decomposing and long conversion cycles, so as to achieve easy absorption and reduce agricultural resources waste, the effect of improving soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

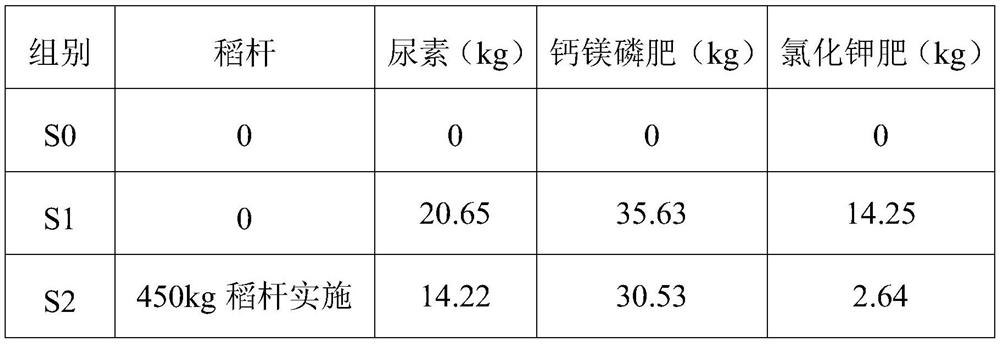

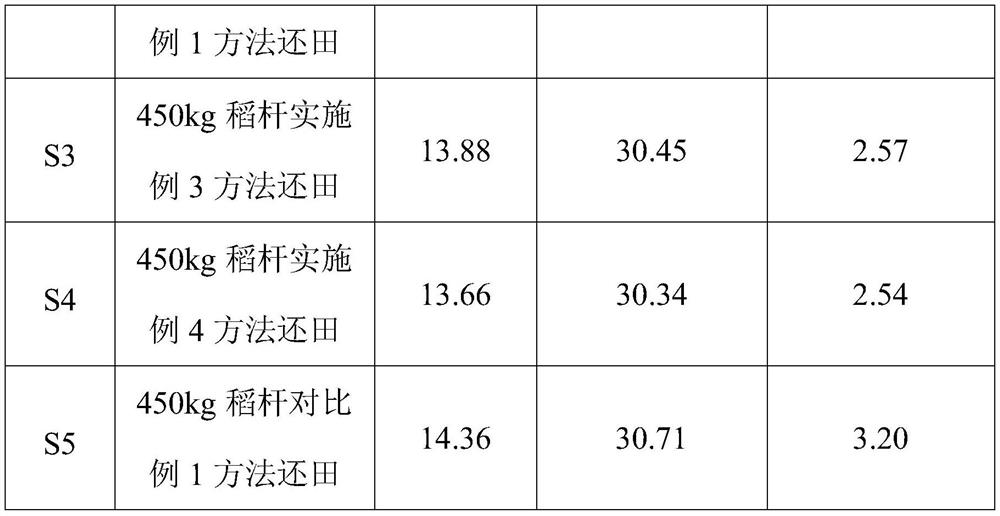

Examples

Embodiment 1

[0024] The present embodiment provides a method for returning rice straws to the field after fast rot, comprising the following steps:

[0025] (1) Chop the rice straws into short straws with a length of less than 20cm, and lay the short straw layers into piles, the thickness of a single layer is 30cm, the number of layers is 4, and the water content of the short straws can reach 65-70% by spraying water on each layer. At the same time, the microbial starter is sprinkled on the short rod, and the addition amount of the microbial fermentation agent is 4% of the weight of the short rod, and compost fermentation is carried out; , 6 parts of brown sugar; Described microbial mixed microbial inoculum is made up of 4 parts by weight of Bacillus subtilis, 8 parts of Trichoderma konzei, 6 parts of white rot fungi, and 5 parts of Aspergillus niger;

[0026] (2) When the compost fermentation process is carried out for 15 days, the stacked fermentation short rods are turned over, and the ...

Embodiment 2

[0029] The present embodiment provides a method for returning rice straws to the field after fast rot, comprising the following steps:

[0030] (1) Chop the rice straws into short straws with a length of less than 20 cm, and lay the short straw layers into piles, the thickness of a single layer is 40 cm, the number of layers is 4, and the water content of the short straws can reach 65-70% by spraying water on each layer. At the same time, the microbial starter is sprinkled on the short rod, and the addition amount of the microbial fermentation agent is 5% of the weight of the short rod, and compost fermentation is carried out; , 5 parts of brown sugar; Described microbial mixed microbial inoculum is made up of 3 parts by weight of Bacillus subtilis, 6 parts of Trichoderma konzei, 5 parts of white rot fungus, 6 parts of Aspergillus niger;

[0031] (2) when the compost fermentation treatment is carried out for 15 days, the stacked fermentation short rods are turned over, and the...

Embodiment 3

[0034] The present embodiment provides a method for returning rice straws to the field after fast rot, comprising the following steps:

[0035] (1) Chop the rice straws into short straws with a length of less than 20cm, and lay the short straw layers into piles, the thickness of a single layer is 30cm, the number of layers is 4, and the water content of the short straws can reach 65-70% by spraying water on each layer. At the same time, the microbial starter is sprinkled on the short rod, and the addition amount of the microbial fermentation agent is 4% of the weight of the short rod, and compost fermentation is carried out; , 6 parts of brown sugar; Described microbial mixed microbial inoculum is made up of 4 parts by weight of Bacillus subtilis, 8 parts of Trichoderma konzei, 6 parts of white rot fungi, and 5 parts of Aspergillus niger;

[0036] (2) when the compost fermentation process is carried out for 15 days, the stacked fermentation short rods are turned over, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com