Formula and preparation process of PC material with permanent fog resistance, scratch resistant and high transparency

A scratch-resistant and anti-fog technology, applied in the field of PC materials, can solve the problems that are difficult to meet the requirements of permanent anti-fog and anti-scratch, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

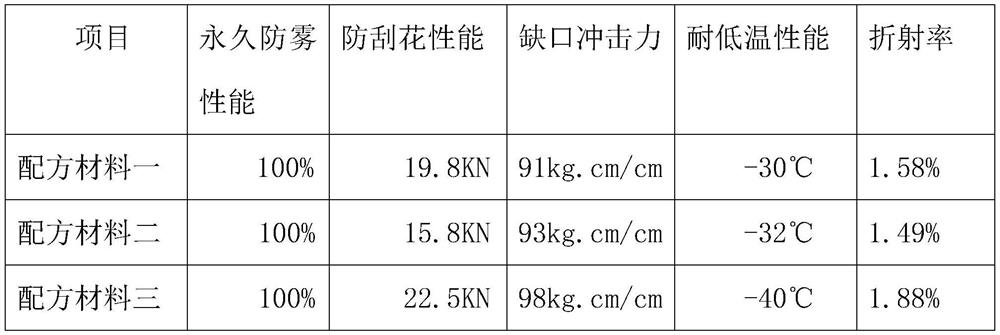

Examples

Embodiment 1

[0023] A permanent anti-fog and scratch-resistant high-transparency PC material formula, including 80 parts of PC resin, 2 parts of monoglyceride stearate, 1 part of high molecular polyester, 2 parts of butadiene, 2 parts of high polyglycidyl ester, 1 part of alkyl silicone oil, 1 part of crosslinking agent, 1 part of antioxidant.

[0024] Based on the above ratio of raw materials, each portion is measured as 1 kg: a preparation process for a permanent anti-fog, scratch-resistant, and highly transparent PC material formula is provided, including the following steps:

[0025] Step 1: Weigh 80 kg of PC resin and put it into a mixer to fully stir for 40 minutes and then transfer it to the reaction kettle; wherein, the speed of the mixer is controlled at 200r / min;

[0026] The second step: weigh 4 kg of monoglyceride stearate, 3 kg of high molecular polyester, 3 kg of butadiene, 4 kg of high polyglycidyl ester, 3 kg of alkyl silicone oil, 1 kg of crosslinking agent and anti 1 kg ...

Embodiment 2

[0030] A permanent anti-fog and scratch-resistant high-transparency PC material formula, including 120 parts of PC resin, 6 parts of monoglyceride stearate, 5 parts of high molecular polyester, 5 parts of butadiene, 6 parts of high polyglycidyl ester, 5 parts of alkyl silicone oil, 3 parts of crosslinking agent, 3 parts of antioxidant.

[0031] Based on the above raw material ratio, a preparation process of a permanent anti-fog, scratch-resistant and highly transparent PC material formula is provided, including the following steps:

[0032] Step 1: Weigh 120 kg of PC resin and put it into a mixer to fully stir for 40 minutes and then transfer it to the reaction kettle; wherein, the speed of the mixer is controlled at 300r / min;

[0033] The second step: weigh 6 kg of monoglyceride stearate, 5 kg of high molecular polyester, 5 kg of butadiene, 6 kg of high polyglycidyl ester, 5 kg of alkyl silicone oil, 3 kg of crosslinking agent, 3 kilograms of oxygen agent were put into the r...

Embodiment 3

[0037] A permanent anti-fog and scratch-resistant high-transparency PC material formula, including 100 parts of PC resin, 4 parts of monoglyceride stearate, 3 parts of high molecular polyester, 3 parts of butadiene, 4 parts of high polyglycidyl ester, 3 parts of alkyl silicone oil, 1 part of crosslinking agent, 1 part of antioxidant.

[0038] Based on the above raw material ratio, a preparation process of a permanent anti-fog, scratch-resistant and highly transparent PC material formula is provided, including the following steps:

[0039] Step 1: Weigh 100 kg of PC resin and put it into a mixer to fully stir for 40 minutes and then transfer it to a reaction kettle; wherein, the speed of the mixer is controlled at 200-300r / min;

[0040] The second step: weigh 4 kg of monoglyceride stearate, 3 kg of high molecular polyester, 3 kg of butadiene, 4 kg of high polyglycidyl ester, 3 kg of alkyl silicone oil, 1 kg of crosslinking agent, 1 kg of oxygen agent was put into the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com