A kind of preparation method of electromagnetic shielding pa6/ps composite foam material

A composite foam, electromagnetic shielding technology, applied in the field of electromagnetic shielding, can solve the problems of affecting the reflection and absorption of electromagnetic waves, affecting the electromagnetic shielding efficiency, and adding a large amount of carbon fiber, so as to achieve enhanced electromagnetic shielding efficiency, low density, and short time consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

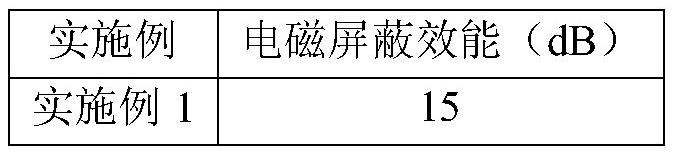

Embodiment 1

[0025] A kind of preparation method of electromagnetic shielding PA6 / PS composite material

[0026] 0.50 g CNTs-OH was added to 85 g molten CL, and sonicated in a water bath at 85 °C for 45 min to obtain a FNCT uniformly dispersed CL / FCNT suspension. 15 g PS and 0.50 g graphene were added at 125 °C, and mechanically stirred for 3 h to obtain a CL / PS / CNTs-OH / graphene suspension. The suspension was placed in a heating mantle at 150 °C for 30 min to remove water under vacuum, 0.4 g of NaOH was added, and 0.6 g of TDI was added for 30 min. After shaking vigorously, it was poured into a 180 °C mold for polymerization for 30 min, and finally CNTs-OH@PA6 / PS / graphene composites.

Embodiment 2

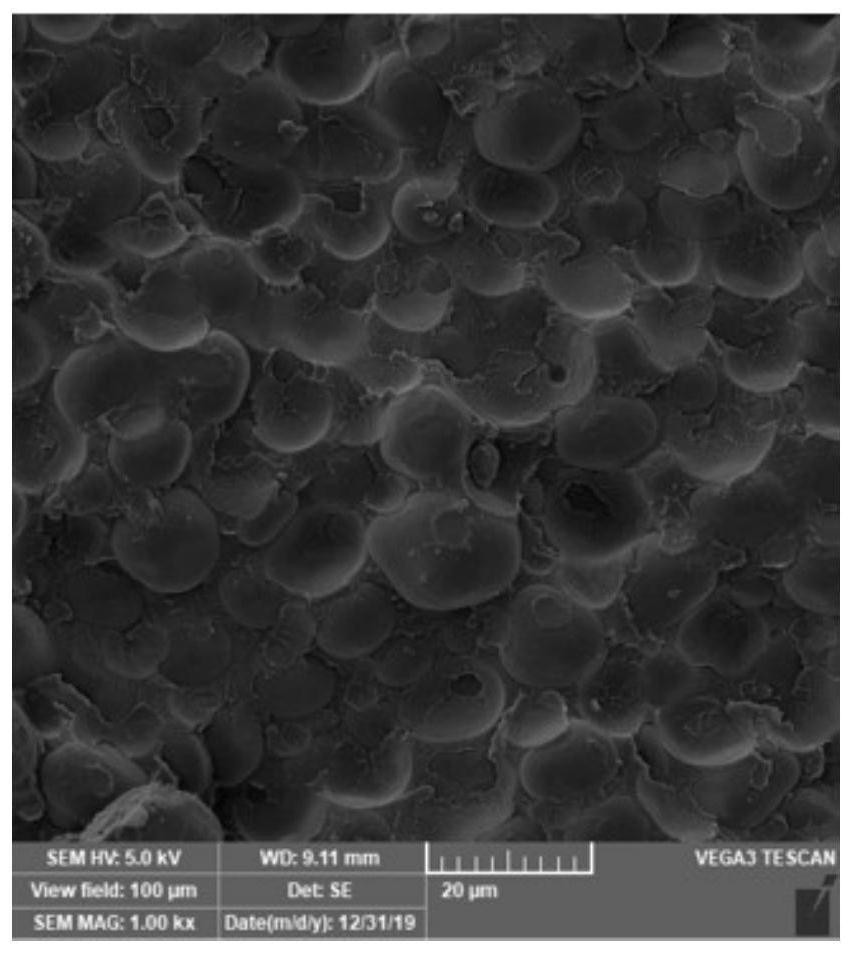

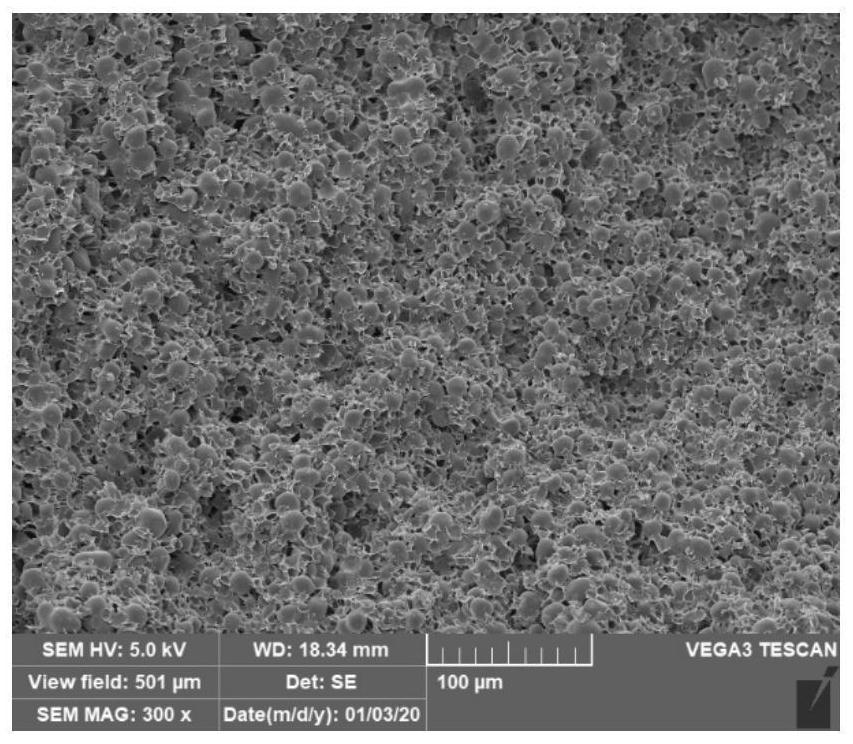

[0028] A kind of preparation method of electromagnetic shielding PA6 / PS composite foam material

[0029] 0.50 g CNTs-OH was added to 85 g molten CL, and sonicated in a water bath at 85 °C for 45 min to obtain a FNCT uniformly dispersed CL / FCNT suspension. 15 g PS and 0.50 g graphene were added at 125 °C, and mechanically stirred for 3 h to obtain a CL / PS / CNTs-OH / graphene suspension. The suspension was placed in a heating mantle at 150°C for 30min vacuum dewatering, 0.4g NaOH was added, water removal was continued for 30min, 0.6g TDI was added, rapidly and vigorously shaken, and then poured into a 180°C mold to polymerize for 30min. The obtained CNTs-OH@PA6 / PS / graphene composites were subjected to supercritical CO at 100 °C, 10.8 MPa and holding pressure for 2 h. 2 After foaming, the CNTs-OH@PA6 / PS / graphene composite foam was finally obtained.

Embodiment 3

[0031] A kind of preparation method of electromagnetic shielding PA6 / PS composite foam material

[0032] 1.00 g of CNTs-OH was added to 85 g of molten CL, and sonicated in a water bath for 45 min at 85 °C to obtain a CL / FCNT suspension with FNCT uniformly dispersed. 15 g PS and 1.00 g graphene were added at 125 °C, and mechanically stirred for 3 h to obtain a CL / PS / CNTs-OH / graphene suspension. The suspension was placed in a heating mantle at 150 °C for 30 min to remove water under vacuum, 0.4 g of NaOH was added, and 0.6 g of TDI was added for 30 min. After shaking vigorously, it was poured into a 180 °C mold for polymerization for 30 min, and finally CNTs-OH@PA6 / PS / graphene composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com