Excavator for building machinery

A technology for construction machinery and excavators, which is applied to mechanically driven excavators/dredgers, etc., can solve problems such as affecting the comfort of drivers, instability of the fuselage, affecting the working efficiency of excavators, etc., to achieve strong grip, improve Driving comfort, weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

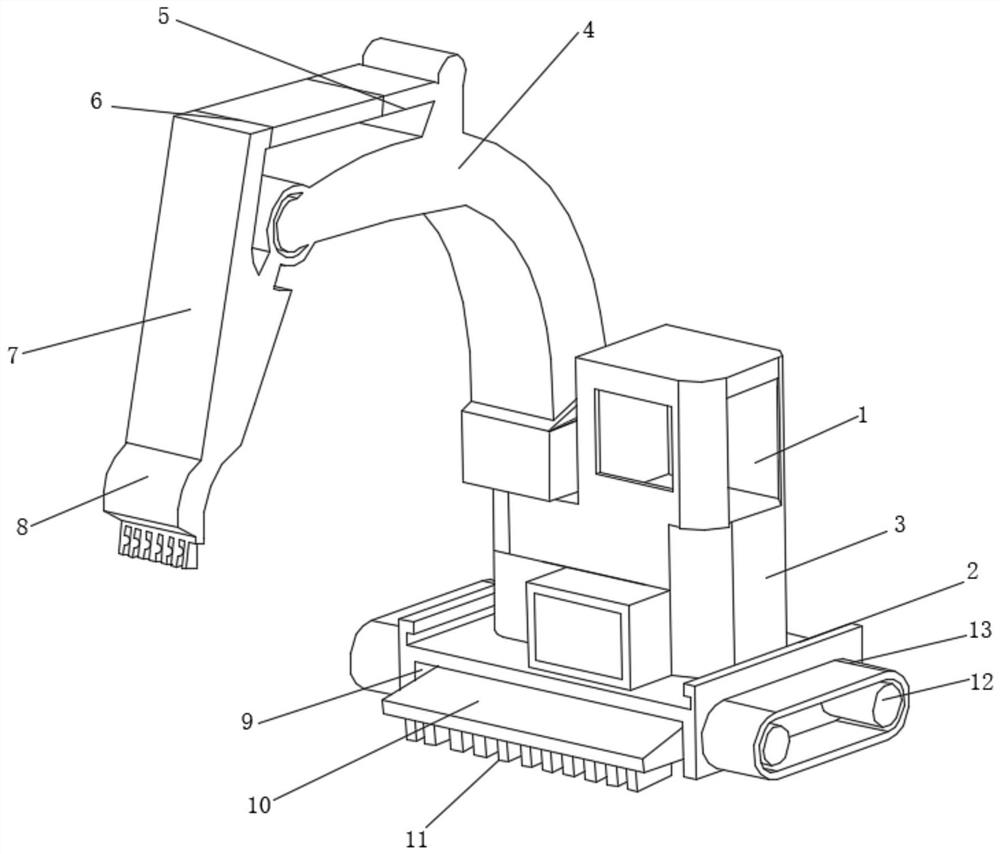

[0030] see figure 1 , the present invention provides a technical solution: an excavator for construction machinery, comprising a cab 1, the bottom of the cab 1 is fixedly connected with a fuselage platform 2, the left side of the cab 1 is fixedly connected with a chassis 3, and the bottom of the chassis 3 The top is rotatably connected with the lower lifting arm 4, and the top of the lower lifting arm 4 is fixedly connected with the connecting rod 6 through the fixed seat 5, and the outer surface of the connecting rod 6 is fixedly connected with the upper lifting arm 7 with the outer surface of the lower lifting arm 4. The bottom of the lifting arm 7 is fixedly connected with a gripper 8, and the bottom of the gripper 8 is uniformly and fixedly connected with gripping teeth, and the bottom of the cab 1 is fixedly connected with a radiator in front of the fuselage platform 2, and the bottom of the fuselage platform 2 is provided with There is a through groove 9, the inner surfa...

Embodiment 2

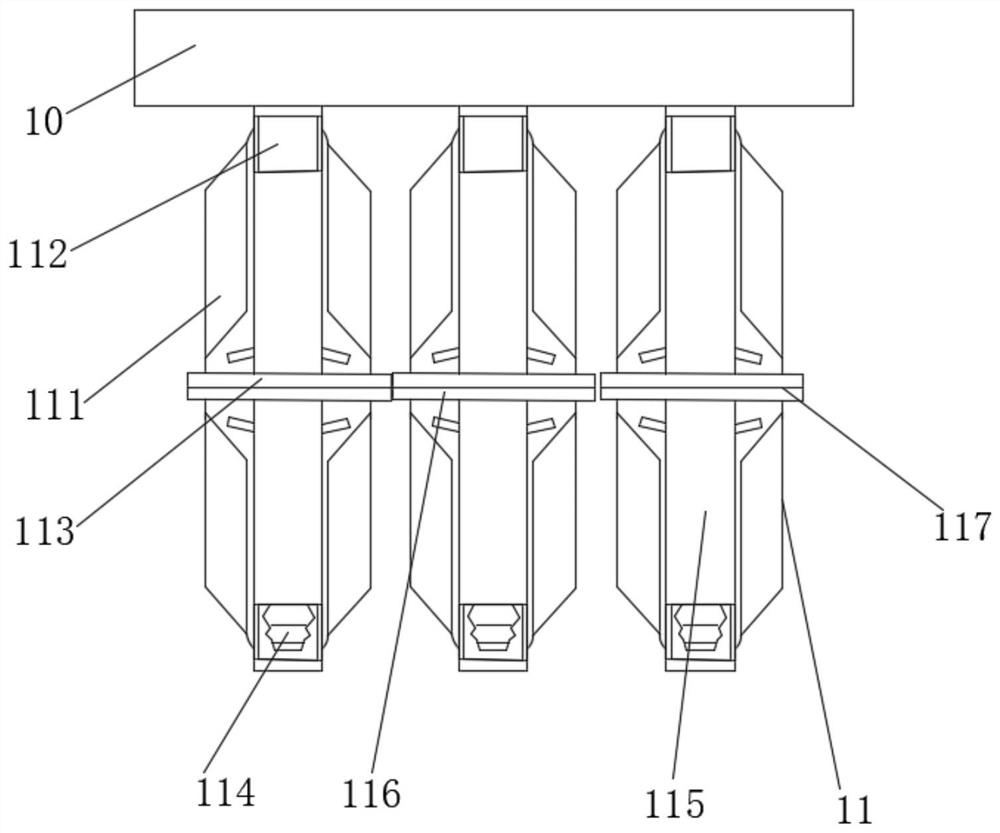

[0032] see Figure 2-3 , the present invention provides a technical solution: the fixing mechanism 11 includes a special-shaped casing 111, the inner surface of the special-shaped casing 111 is slidingly connected with a piston rod 112, the top of the piston rod 112 is fixedly connected with the bottom of the fixed plate 10, and the bottom of the piston rod 112 The bottom is fixedly connected with a folding plate 113, the bottom of the inner surface of the special-shaped casing 111 is fixedly connected with a cardan shaft 114, the top of the cardan shaft 114 is fixedly connected with a vertical rod 115, and the top of the vertical rod 115 is fixedly connected with a lower opening plate 116, The top of the lower opening plate 116 is flexibly connected with the bottom of the folding plate 113 .

[0033] The outer surface of the lower opening plate 116 is an irregular curved surface, the outer surface of the lower opening plate 116 is fixedly connected with a connecting shaft, an...

Embodiment 3

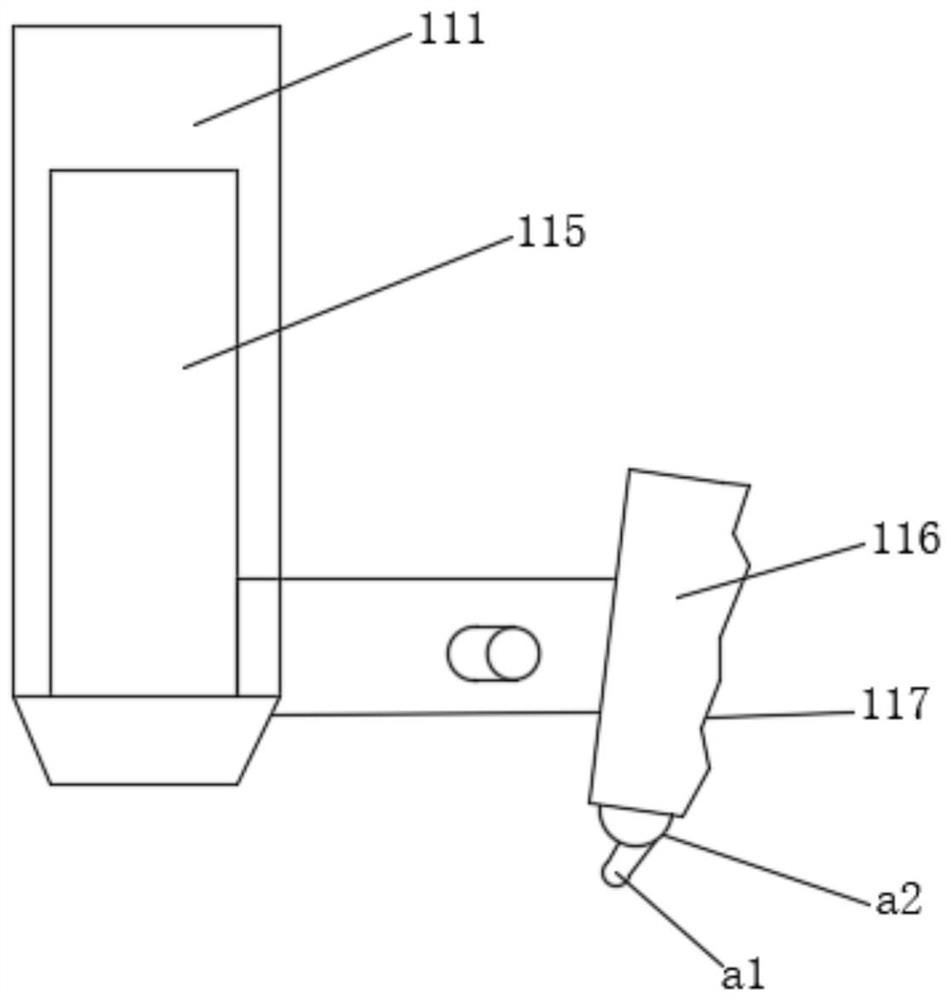

[0035] see Figure 4, the present invention provides a technical solution: the stabilizing mechanism 117 includes a fixed vertical tooth a1, the top of the fixed vertical tooth a1 is rotationally connected with the outer surface of the lower opening plate 116, and the outer surface of the fixed vertical tooth a1 is fixedly connected with a fastening component a2. The contact area between the mechanism and the ground soil is increased, and the frictional force between the fixed vertical teeth a1 and the ground is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com