Multi-station anchor rod system

A multi-station and bolt technology, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc. The effect of high construction efficiency, safe operation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

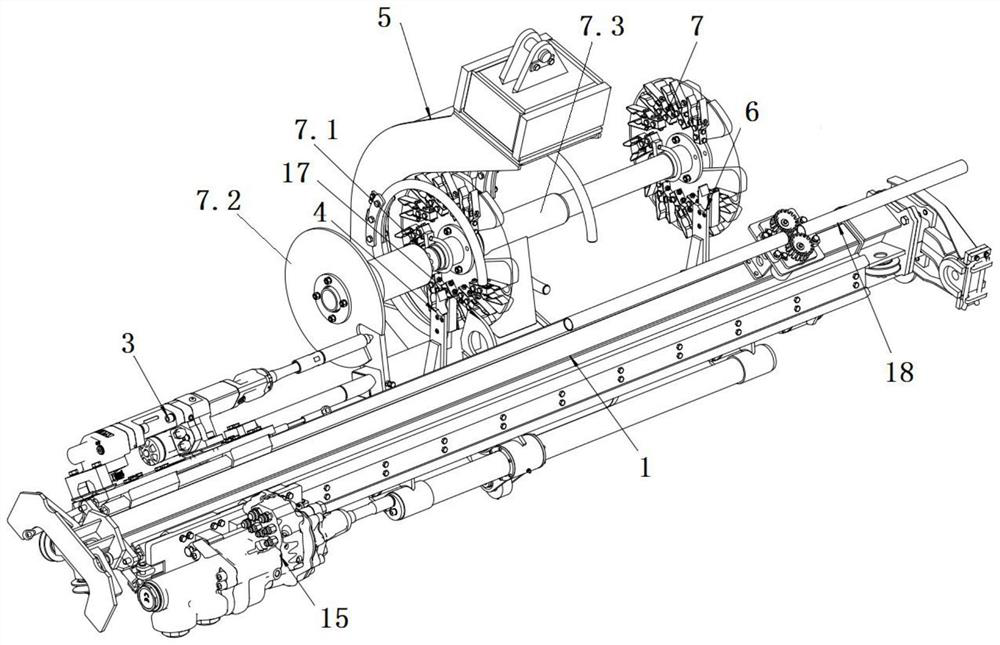

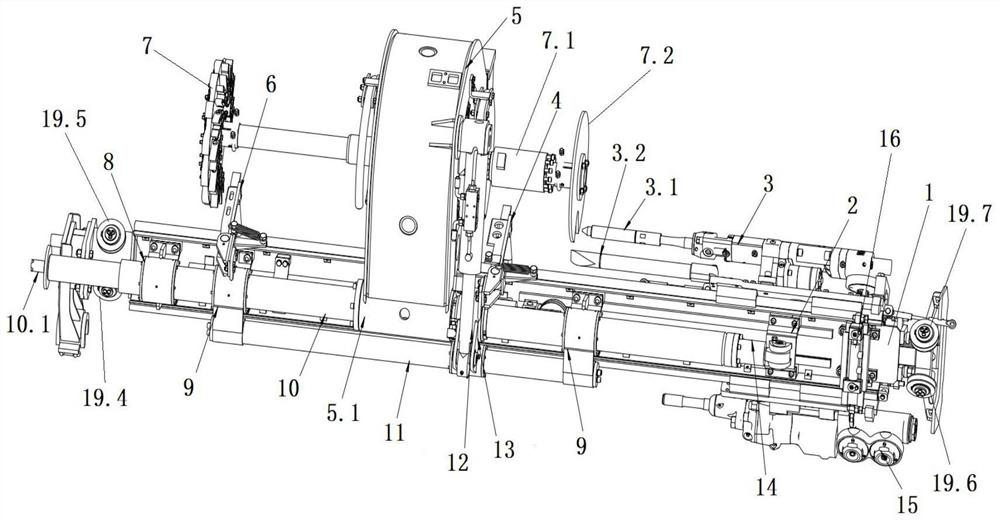

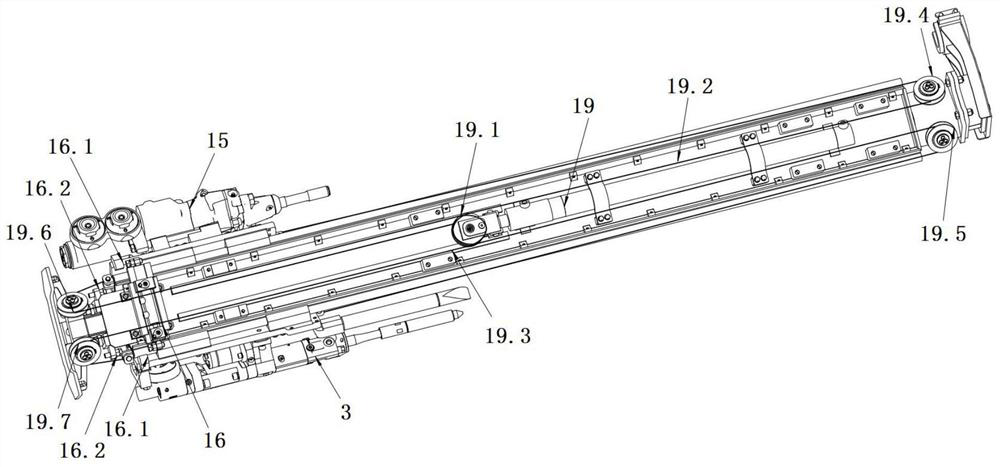

[0042] see Figure 1-10 , a multi-station bolt system, comprising a double-track main beam 1, a bolt propulsion device 3, a slewing bearing 5, a bolt storehouse 7, a drilling device 15, a grouting device 18 and a propulsion system, the double-track main beam 1 It is rotatably connected with the slewing support 5 through a rotating mechanism, the anchor bar library 7 is arranged on the slewing support 5, the double-track main beam 1 includes a first track 1.1 and a second track 1.2 arranged in the same direction, and the first The track 1.1 and the second track 1.2 are arranged on opposite sides of the double-track main beam 1, and the bolt propulsion device 3 and the drilling device 15 are respectively slidably arranged on the first track 1.1 and the second track 1.2; the propulsion system and The grouting device 18 is arranged on another group of opposite sides of the double-track main beam 1, and the propulsion system is connected with the bolt propulsion device 3 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com