Miniature high-isolation microwave double-frequency power divider

A technology of high isolation and power divider, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problems of mutual influence of output signals, unfavorable miniaturization design, and short distance between two output ports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

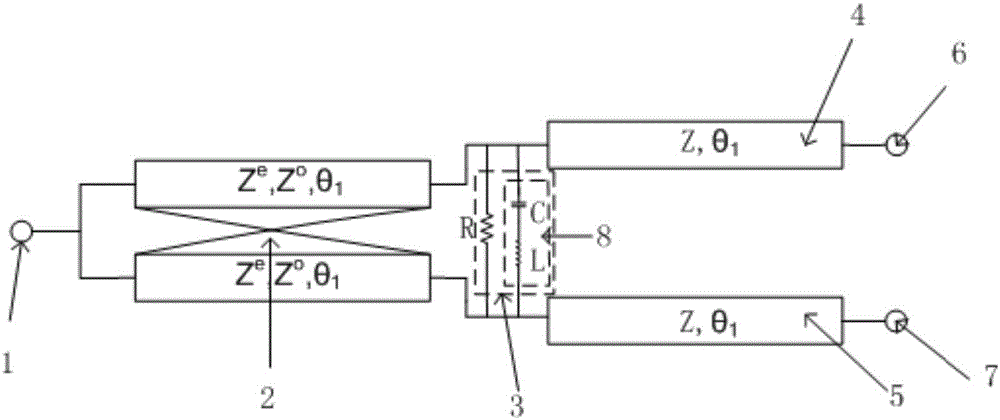

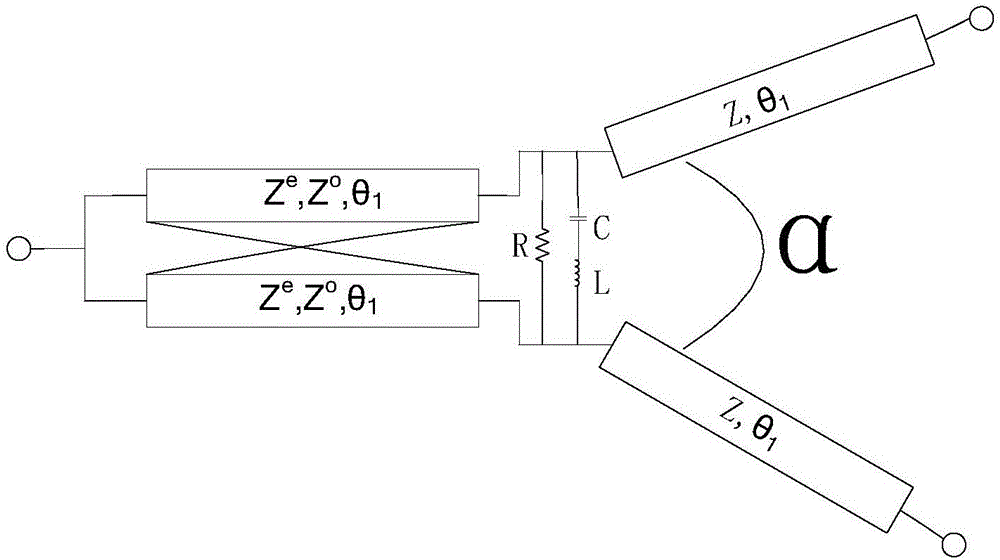

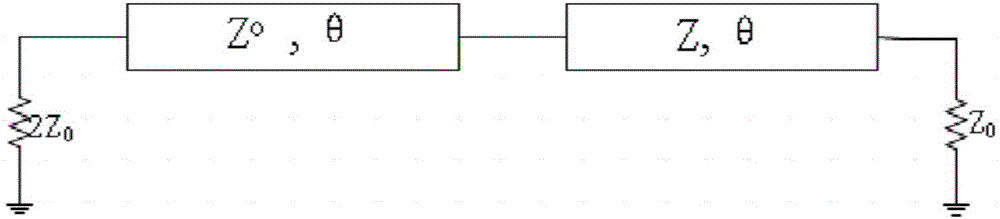

[0045] This embodiment discloses a miniaturized high-isolation microwave dual-frequency power divider, such as Figure 1a and 1b As shown, it includes an input port 1, a coupled line 2, an isolation network 3, a first transmission line 4, a second transmission line 5, a first output port 6 and a second output port 7, and the coupled line 2 includes a first port and the second port, and the third port and the fourth port at the other end of the coupled line 2.

[0046] The input port 1 is connected to the first port and the second port of the coupled line 2, the third port of the coupled line 2 is connected to the first output port 6 through the first transmission line 5, and the fourth port of the coupled line 2 is connected to the second port through the second transmission line 5. Output port 7; the connection between the third port of the coupling line 2 and the first transmission line 4 is connected to one end of the isolation network 3, and the connection between the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com