A metallographic method for displaying the three-dimensional structure of the silicon-rich phase in the aluminum-silicon coating

A three-dimensional structure, aluminum-silicon technology, which is applied in the field of displaying the three-dimensional structure of the silicon-rich phase in the aluminum-silicon coating by the metallographic method, can solve the problems of the phase structure of the aluminum-coated silicon coating remaining, and no three-dimensional phase structure is found, and achieve low detection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

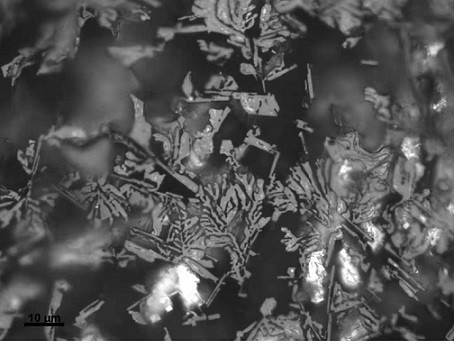

[0029] A method for displaying the three-dimensional structure of a silicon-rich phase in an aluminum-silicon coating by a metallographic method, which comprises sample preparation, chemical corrosion, and microscope observation, specifically:

[0030] (1) Sample preparation: Take the aluminum-silicon coated steel plate (1500+AS grade), cut a 15mm×15mm sample, put the surface of the sample coating into the inlay machine horizontally for inlaying, and the surface of the inlaid sample coating is completely exposed. , and then polishing, specifically: spraying water and 2.5μm high-efficiency metallographic polishing agent on the 200mm pressure-sensitive adhesive woolen polishing cloth in turn, and then polishing for 30s at a polishing machine speed of 300 rpm.

[0031] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution is composed of an aqueous solution of hydrochloric acid with a volume concentrat...

Embodiment 2

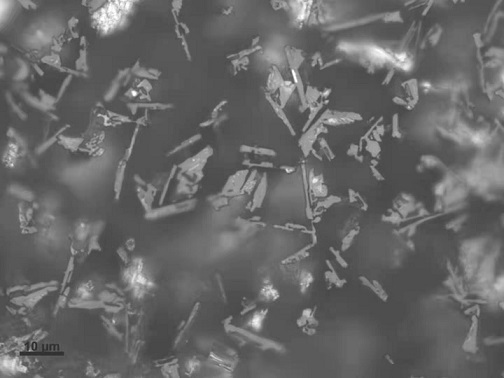

[0035] A method for displaying the three-dimensional structure of a silicon-rich phase in an aluminum-silicon coating by a metallographic method, which comprises sample preparation, chemical corrosion, and microscope observation, specifically:

[0036] (1) Sample preparation: Take the aluminum-silicon coated steel plate (DC52D+AS grade), cut a 20mm×20mm sample, put the surface of the sample coating into the inlay machine horizontally for inlaying, and the surface of the inlaid sample coating is completely exposed. , and then polishing, specifically: spraying water and 0.5μm high-efficiency metallographic polishing agent on the 250mm pressure-sensitive adhesive woolen polishing cloth in turn, and then polishing at 600 rpm for 20s.

[0037] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution is composed of an aqueous solution of hydrochloric acid with a volume concentration of 12% and an aqueous so...

Embodiment 3

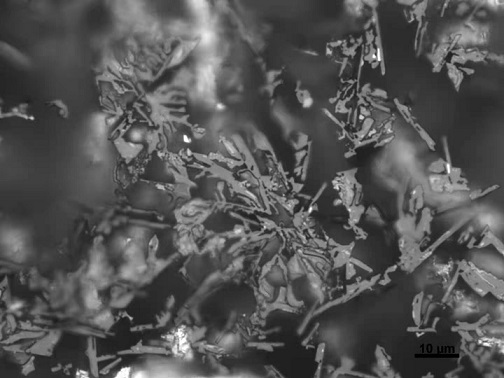

[0041] A method for displaying the three-dimensional structure of a silicon-rich phase in an aluminum-silicon coating by a metallographic method, which comprises sample preparation, chemical corrosion, and microscope observation, specifically:

[0042] (1) Sample preparation: Take the aluminum-silicon coated steel plate (DC51D+AS grade), cut a 10mm×10mm sample, put the surface of the sample coating into the inlay machine horizontally for inlaying, and the surface of the inlaid sample coating is completely exposed. , and then polishing, specifically: spraying water and 1.5μm high-efficiency metallographic polishing agent on the 200mmmm pressure-sensitive adhesive woolen polishing cloth in turn, and then polishing at 450 rpm for 25s.

[0043] (2) Chemical corrosion: Put the sample prepared in step (1) into the corrosion solution for chemical corrosion. The corrosion solution is composed of an aqueous solution of hydrochloric acid with a volume concentration of 11% and an aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com