Defect detection method for high-brightness and high-reflectivity part

A defect detection and parts technology, which is applied in the field of high-brightness and high-reflection parts defect detection, can solve the problems of fixed 2D camera angle, damage to the eyesight of inspectors, and inability to cover all areas of parts, etc., to achieve the effect of increasing versatility and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0026] see Figure 1 to Figure 7 , the embodiment of the present invention includes:

[0027] A method for detecting defects of high-brightness and high-reflection parts, comprising the following steps:

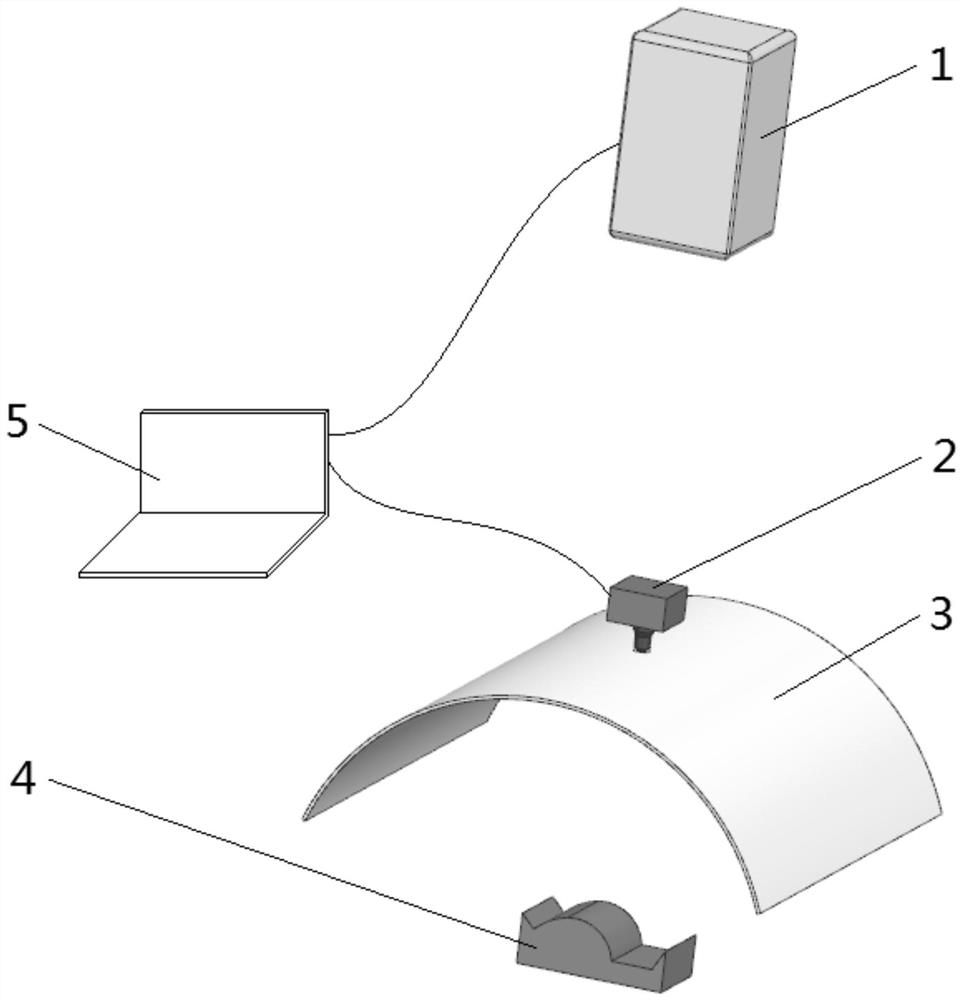

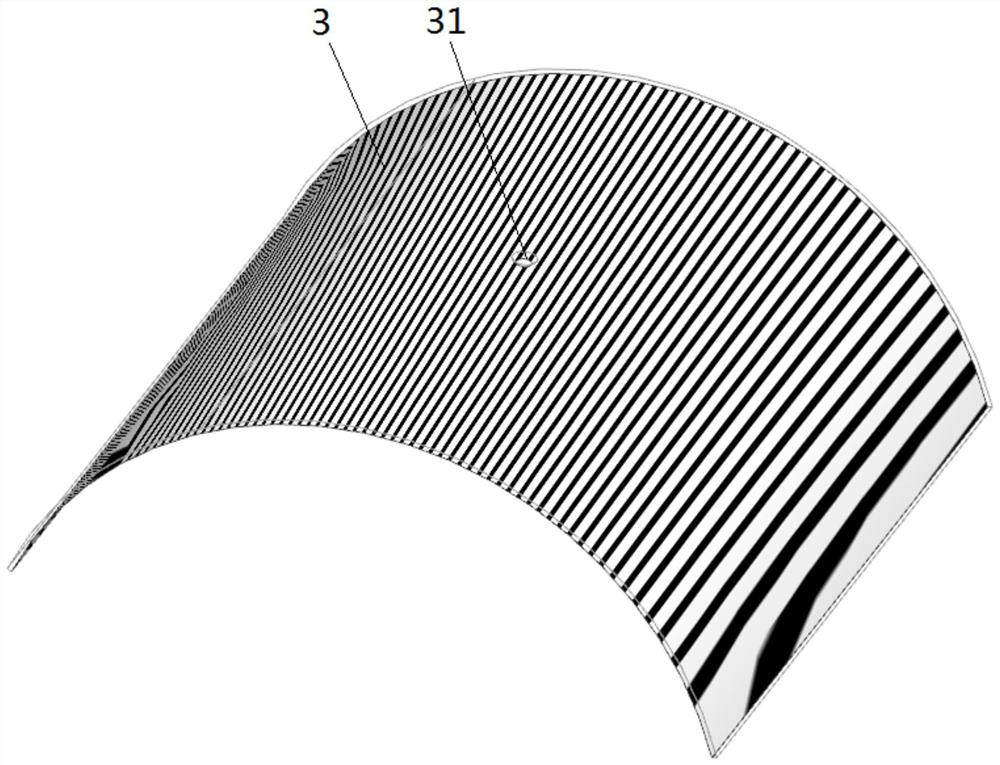

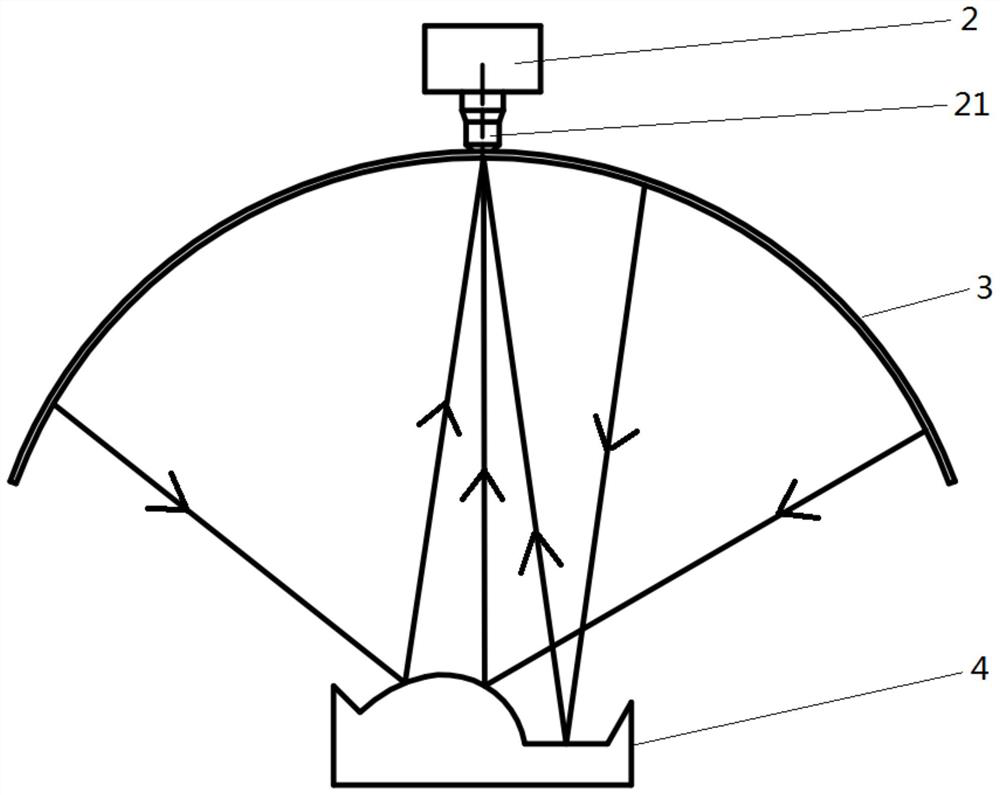

[0028] Step 1: Prepare projector 1, industrial camera 2, arc-shaped translucent plate 3, measured part 4 and computer 5, connect the projector 1 and industrial camera 2 to the computer 5; The measuring part 4 is placed at the arc center of the arc-shaped translucent plate 3, the industrial camera 2 is placed outside the arc-shaped translucent plate 3, and at the center of the arc-shaped translucent plate 3 A circular hole 31 is opened, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com