A LED epitaxy structure

A technology of light-emitting diodes and epitaxial structures, which is applied in the field of optoelectronics, can solve the problems of large bandwidth and cannot effectively reflect incident light, etc., and achieve the effects of improving reflection angle, light extraction efficiency, and high reflection spectrum width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

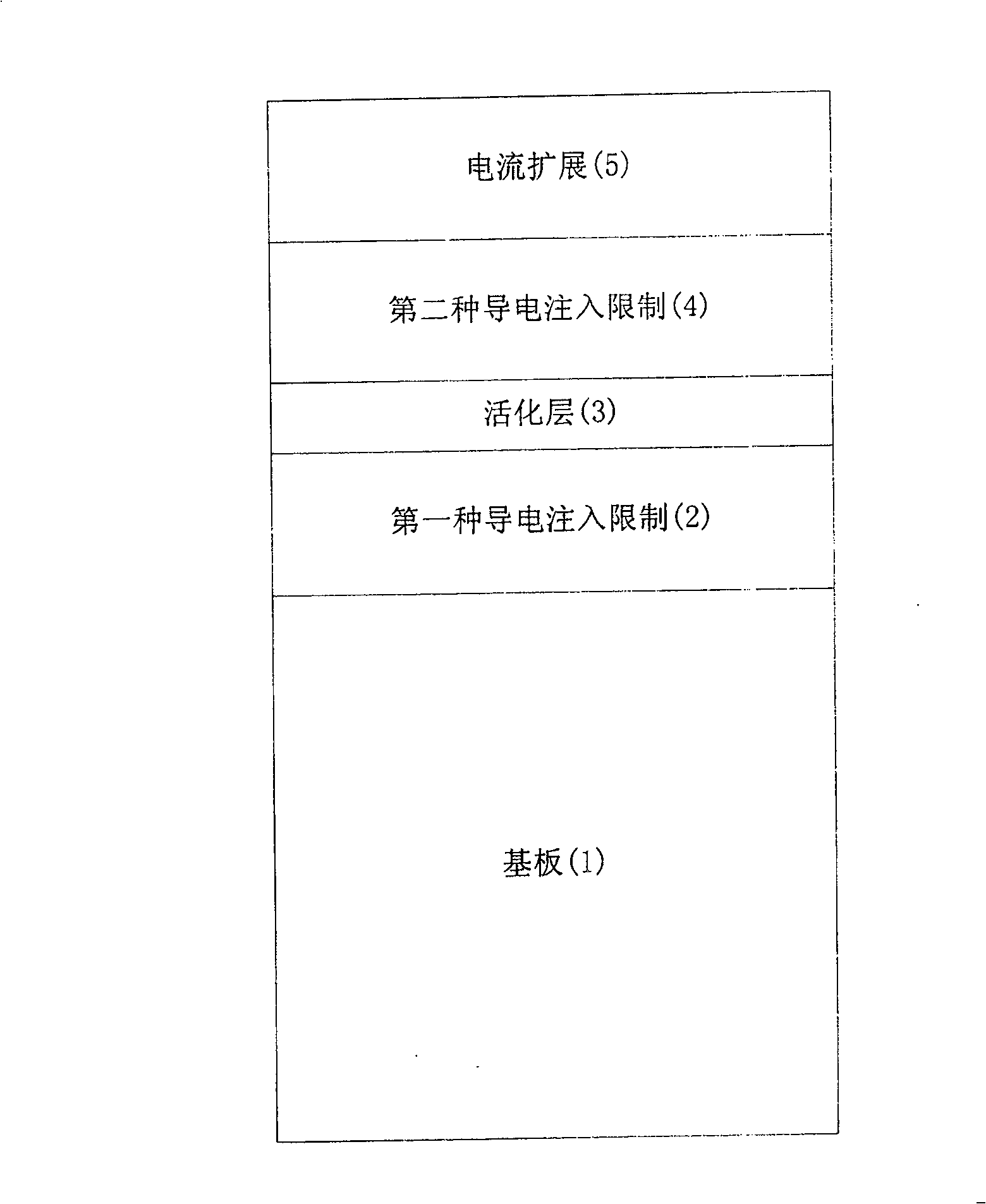

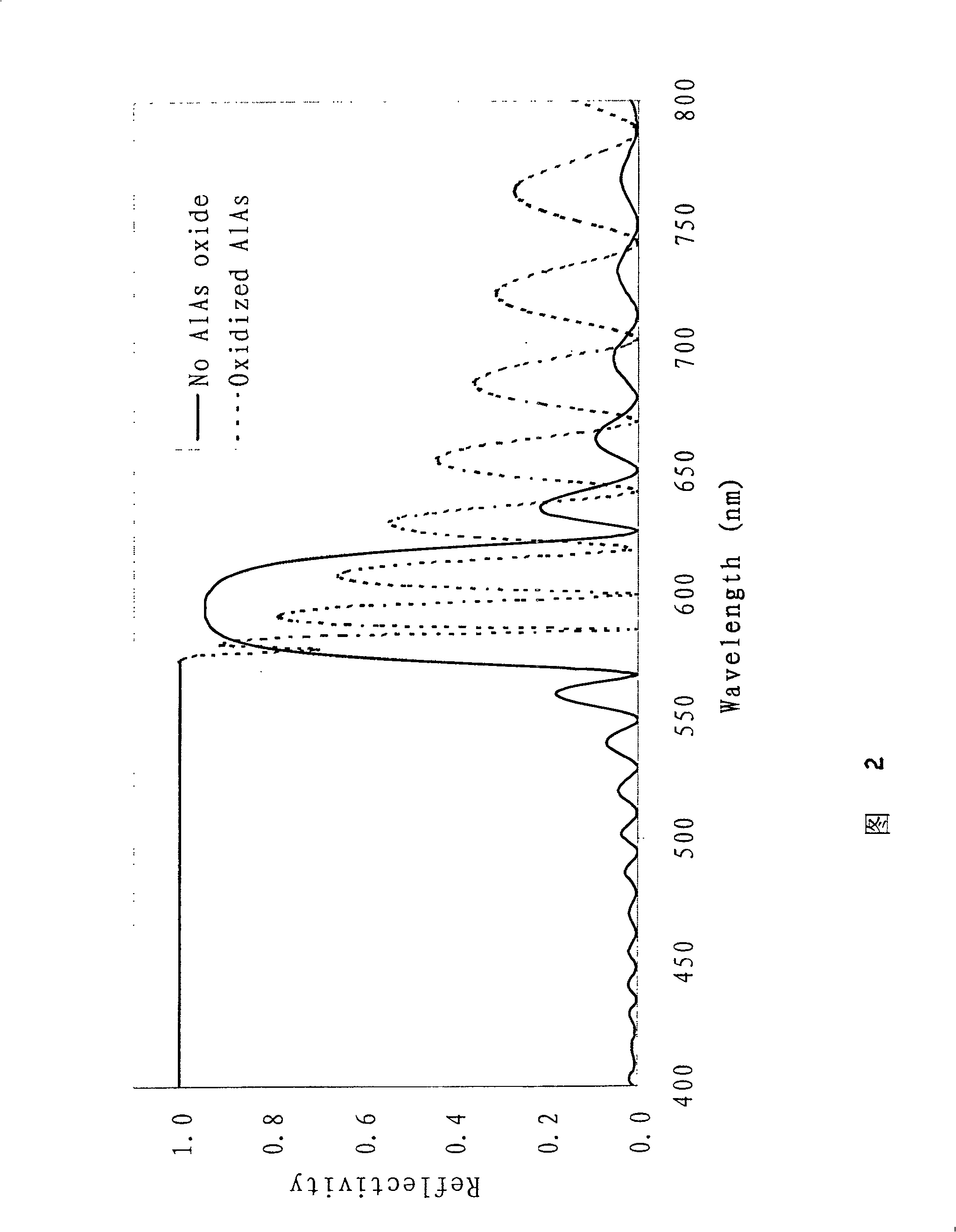

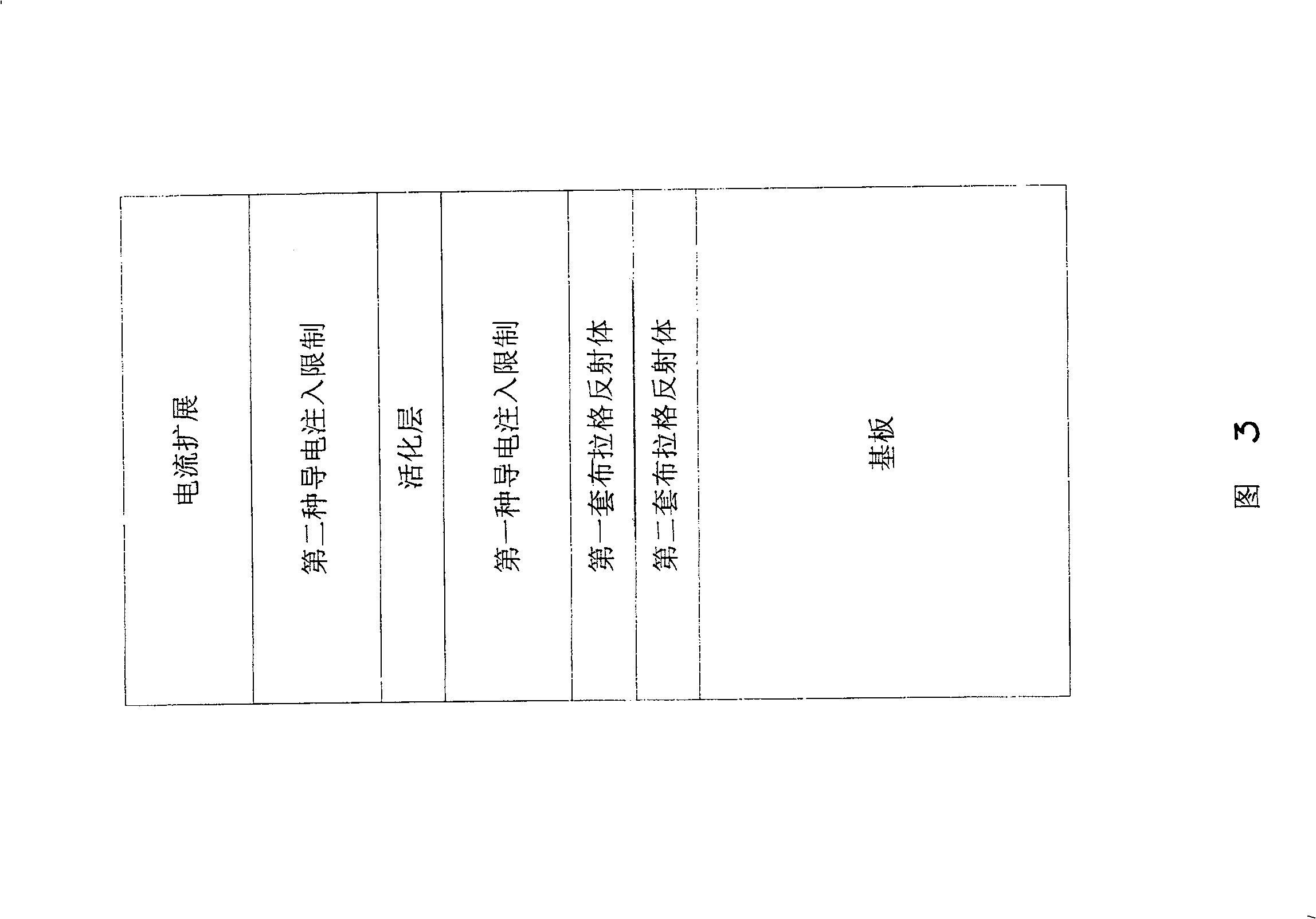

[0013] In the present invention, at least two sets of Bragg reflectors are grown between the conventional light-emitting diode structure and the gallium arsenide substrate, as shown in Figure 3, the two sets of Bragg reflectors are the Bragg reflectors that need to be oxidized for epitaxy, and then epitaxy does not need to be carried out on them. Oxidized Bragg reflectors, wherein the reflection spectrum of the first set of Bragg reflectors covers the radiated light of the LED, and the reflection spectrum of the other set of Bragg reflectors covers the radiated light of the LED after being oxidized. The first set of Bragg reflectors has the characteristics of conventional Bragg reflectors, and the periodic units are composed of AlGaAs / AlGaAs, or AlGaAs / AlGaInP, or AlGaInP / AlGaInP, or AlGaInP / AlGaAs. One layer of the periodic unit of the second set of Bragg reflectors should have a much larger oxidation rate than the other layer of material in the periodic unit under certain oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com