Wrapping post structure, carrier, lens driving device, photographic device and electronic product

A winding post and carrier technology, which is applied in the field of photographic devices, lens driving devices, electronic products, winding post structures, and carriers, and can solve the problems affecting the accuracy of the lens driving device, affecting the assembly of the lens driving device, and difficult to control the flow of solder paste, etc. problem, to avoid the center of gravity shift of the carrier, reduce the difficulty of injection molding processing, and avoid the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

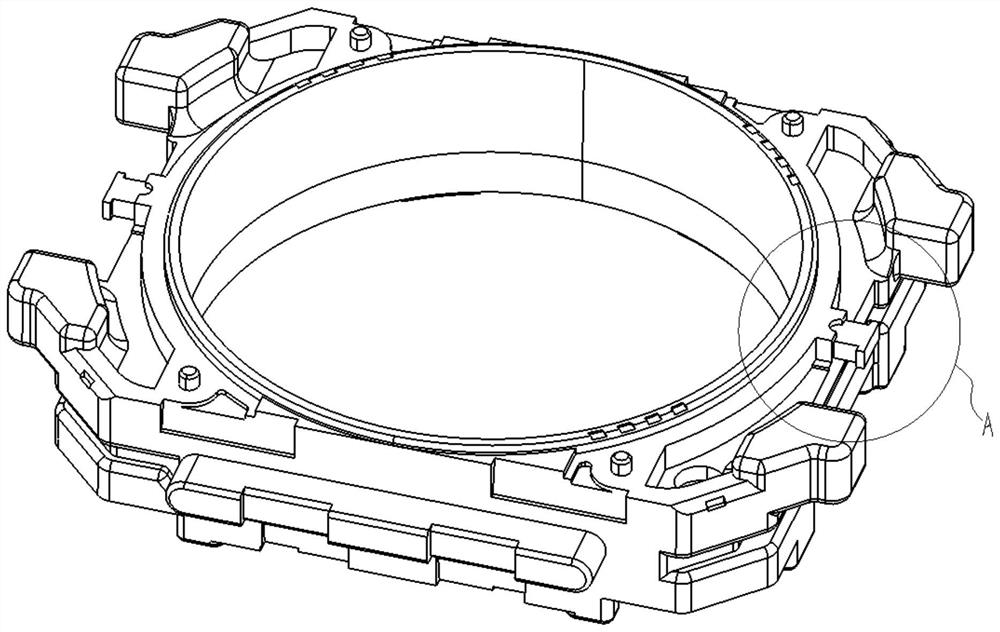

[0037] Embodiment 2: a kind of carrier, such as Figure 7 and Figure 8 As shown, it has the winding post structure described in Embodiment 1, and in this embodiment, the winding post structures are arranged in two groups and arranged symmetrically. This embodiment also includes a carrier body 5, the carrier body 5 is integrally formed with a stepped portion 6 connected to the fixed portion 1, the stepped portion 6 extends to a position of the fixed portion 1 close to the winding portion 2, and is wound around the winding portion 2. The coil wire ends of the portion 2 are attached to the stepped portion 6 .

[0038] Through the integral injection molding of the step part 6 and the fixing part 1, the connection strength between the winding post and the carrier is effectively increased, and at the same time, the difficulty of injection molding of the winding post is reduced. In addition, the step part 6 facilitates winding of the coil end on the winding part 2 .

Embodiment 3

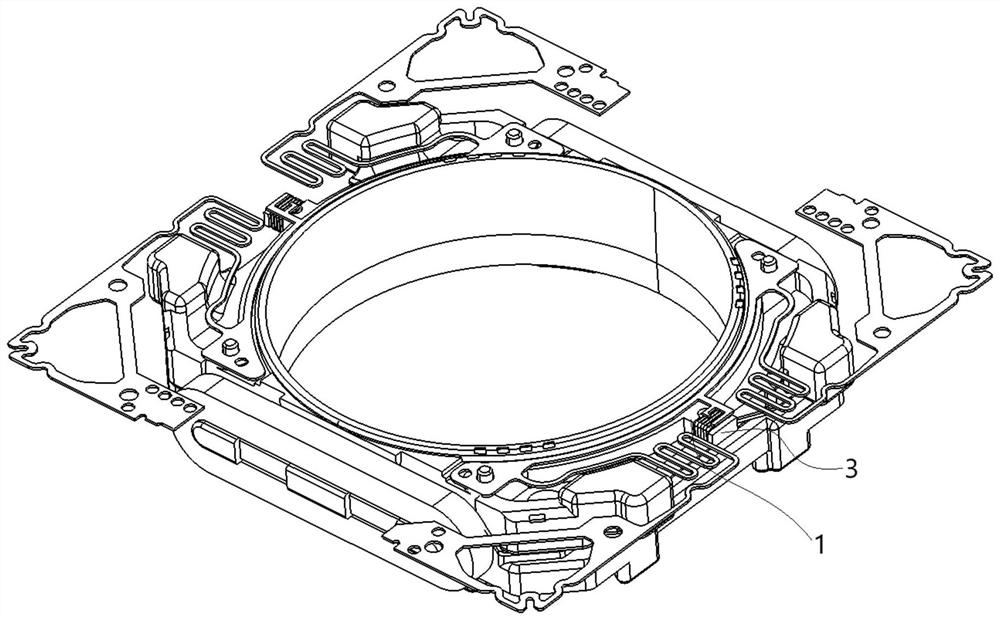

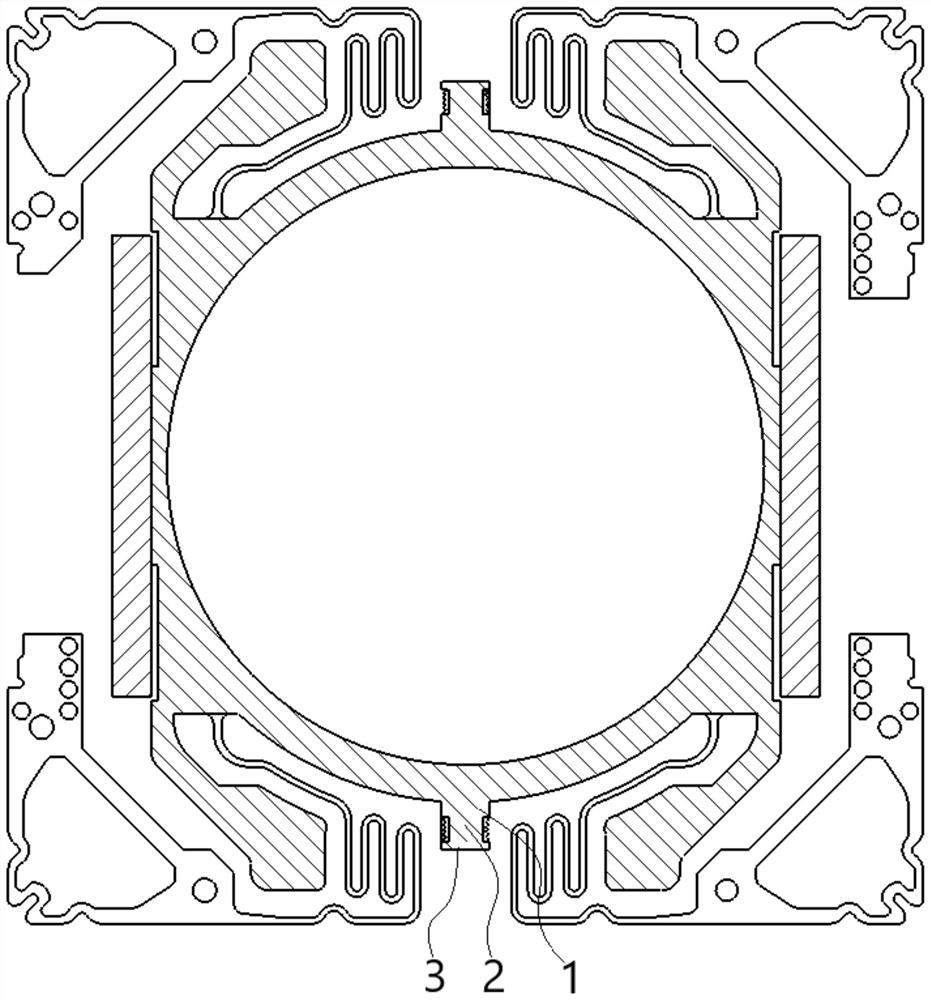

[0039] Embodiment 3: a kind of lens driving device, such as Figure 9 As shown, it has the carrier described in Embodiment 2. Specifically, the lens driving device has the carrier body 5 in Embodiment 2 and the winding post structure disposed on the carrier body 5 . The lens driving device with the above structure ensures that the center of gravity of the carrier is located at the center of the carrier, improves the accuracy of driving the lens movement, and ensures that the lens moves along the optical axis, thereby effectively improving the quality of photographing.

Embodiment 4

[0040] Embodiment 4: a kind of camera device, such as Figure 10 As shown, there is the lens driving device described in Embodiment 3. In the embodiment, the driving structure in the lens driving device drives the corresponding lens to move to achieve focusing. After focusing, the light passes through the lens and enters the photoelectric sensor in the camera device and is converted into an electrical signal, so that the image of the collected photo is converted into electronic data. camera function. The lens driving device and the spring structure in the camera device in this embodiment have been fully described above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com