Mechanical arm safety trajectory tracking control method based on sliding mode

A trajectory tracking and control method technology, applied in the field of control, can solve problems such as reducing position control accuracy, work task interruption, secondary collision, etc., to achieve the effect of reducing complexity, fast response, and high-precision tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific drawings and embodiments.

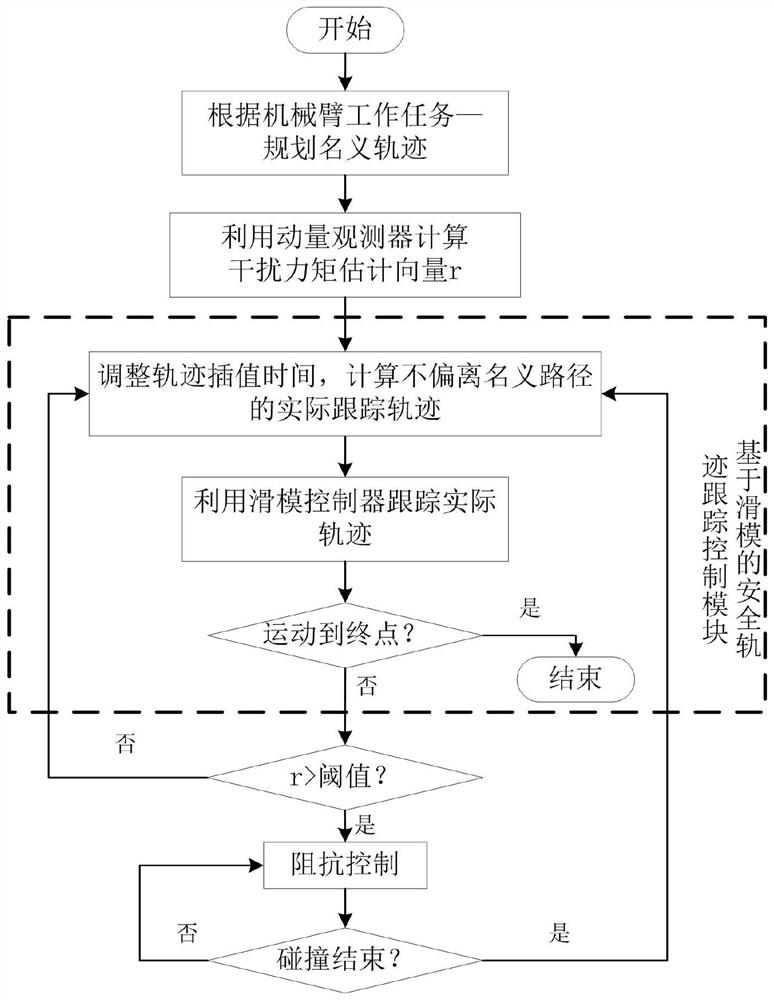

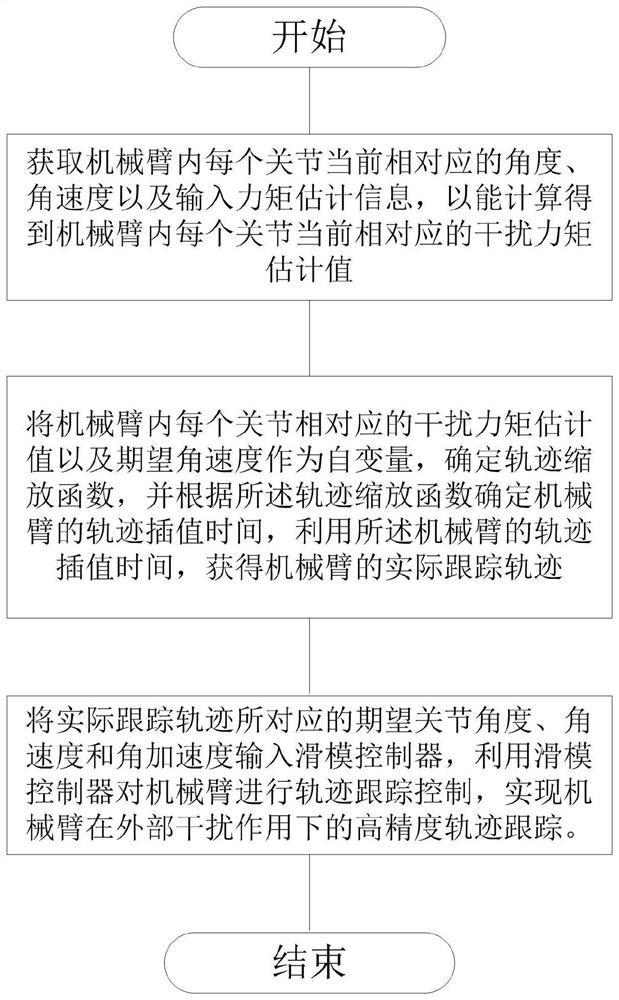

[0038] Such as figure 1 Shown: is the working flow chart of the existing manipulator. Specifically, according to the work tasks of the manipulator, the required nominal trajectory is planned; when the manipulator has no interaction with the external environment, the manipulator tracks the plan When the manipulator is subjected to external disturbance and the external disturbance torque is less than the set threshold, the trajectory interpolation time of the manipulator is corrected by the trajectory scaling function, that is, the movement speed of the manipulator on the nominal trajectory is corrected (when the speed is positive , the mechanical arm moves forward along the nominal trajectory, and when the speed is negative, the mechanical arm moves reversely along the nominal trajectory).

[0039] If the above method cannot ensure that the external disturbance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com