Hot press and product feeding and discharging method

A technology of hot press and hot press mechanism, which is applied in the direction of press, final product manufacturing, battery assembly machine, etc. It can solve the problems of mechanical interference of mechanical jaws, low production capacity, and slow production efficiency, so as to improve production capacity and improve processing The effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

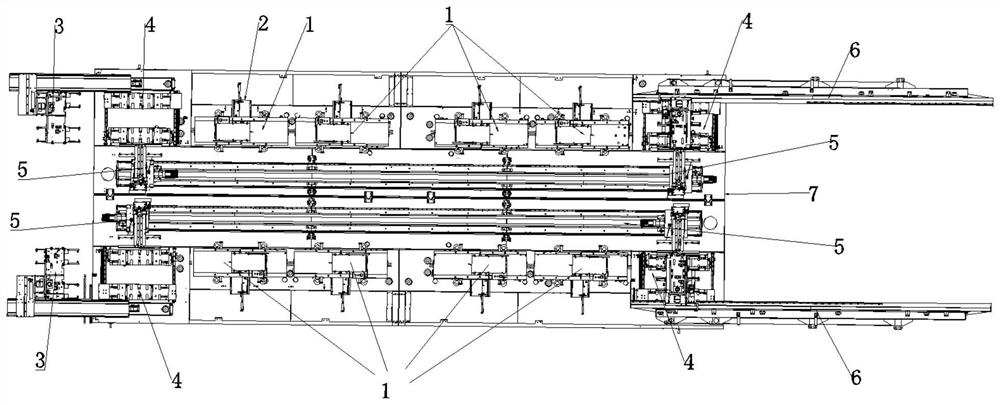

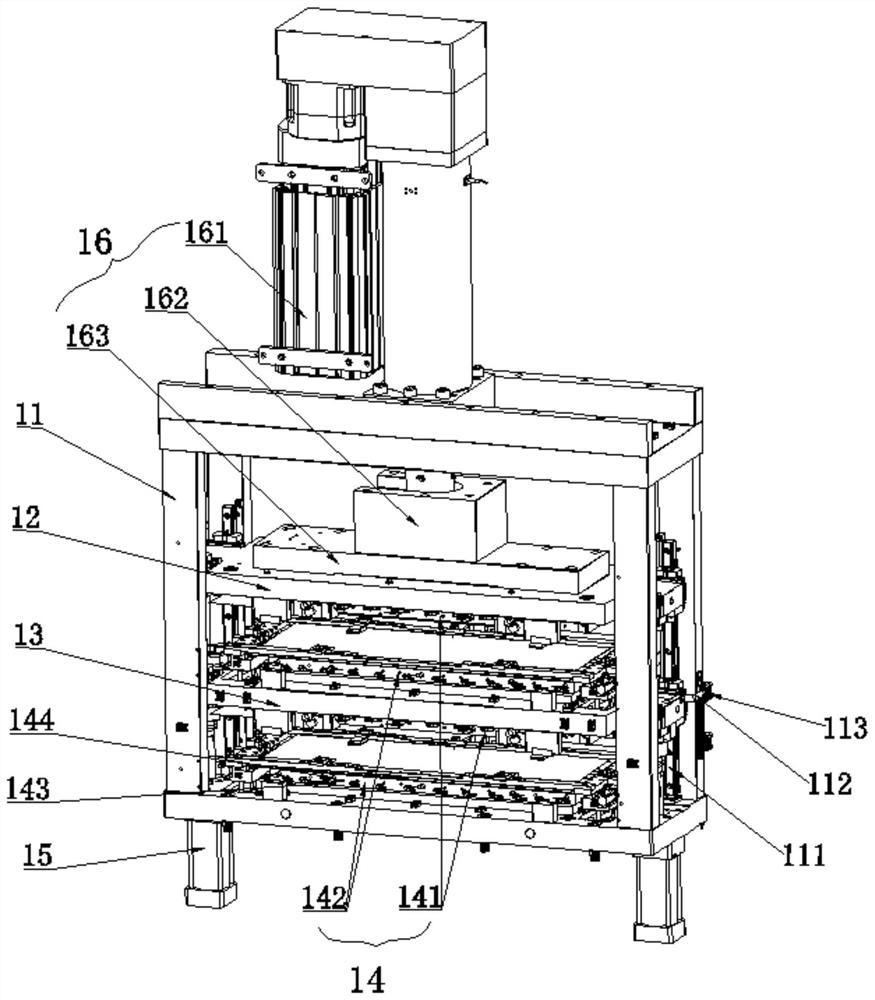

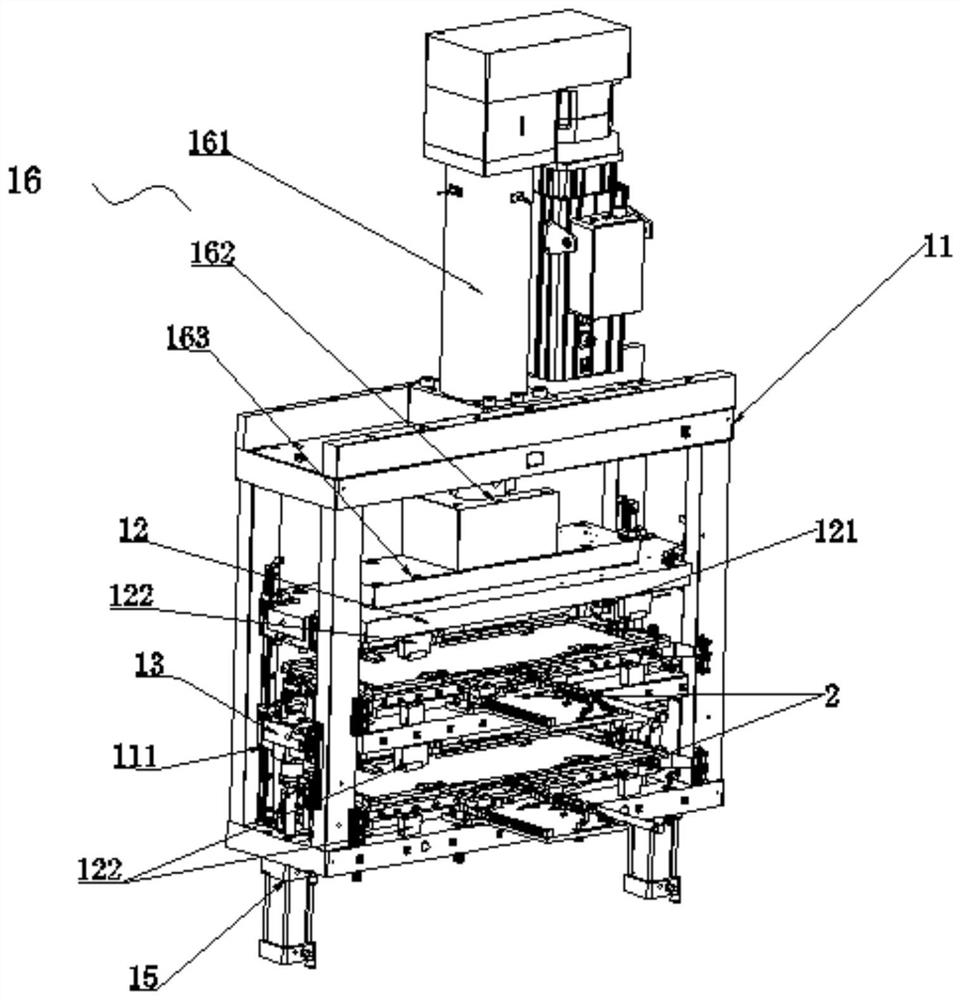

[0041] In order to solve the above technical problems, this embodiment provides a hot press, such as figure 1 Shown, comprise the loading mechanism 3 that is arranged on frame 7 two ends and unloading mechanism 6, be positioned at between loading mechanism 3 and unloading mechanism 6 on frame 7 and arrange several hot-pressing mechanisms 1 side by side, hot-pressing mechanism 1. The battery is hot-pressed, and a transfer platform 4 is respectively provided under the loading mechanism 3 and the unloading mechanism 6. The transfer platform 4 places the battery to be loaded or unloaded, and the transfer platform 4 is located in several hot-pressing mechanisms 1 On both sides of the frame 7, a transfer mechanism 5 is arranged on the side of the transfer platform 4 and the heat press mechanism 1. The transfer mechanism 5 extends along the arrangement direction of the heat press mechanism 1, and the transfer mechanism 5 is used to place the battery on the transfer platform. 4 and th...

Embodiment 2

[0076] The present embodiment provides a heat press machine, which also includes a loading mechanism 3 and an unloading mechanism 6 arranged on a frame 7, a transfer platform 4, several heat press mechanisms 1 arranged side by side, and a battery for placing the battery on the transfer platform 4 and the hot-pressing mechanism 1 are transferred between the transfer mechanism 5, and the multiple hot-pressing mechanisms 1 are loaded and unloaded through the transfer mechanism 5, and then the battery is hot-pressed on the multi-station, and the automatic production greatly improves the production efficiency, and the thermal The pressing mechanism 1 is a double-layer hot pressing mechanism, which can carry out hot pressing processing on two batteries at the same time, greatly increasing the production capacity. The heat-pressing mechanism 1 is provided with a carrying device 2 for supporting the product. The carrying device 2 lifts the product and forms a space for the transfer mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com