Power cable insulation closed terminal and closing method of cable end

A power cable and cable insulation technology, which is applied to cable terminals, cable installation, cable accessories, etc., can solve the problems of inconvenient operation of electric field insulation and sealing, and achieve the effect of saving cable length, occupying less land and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

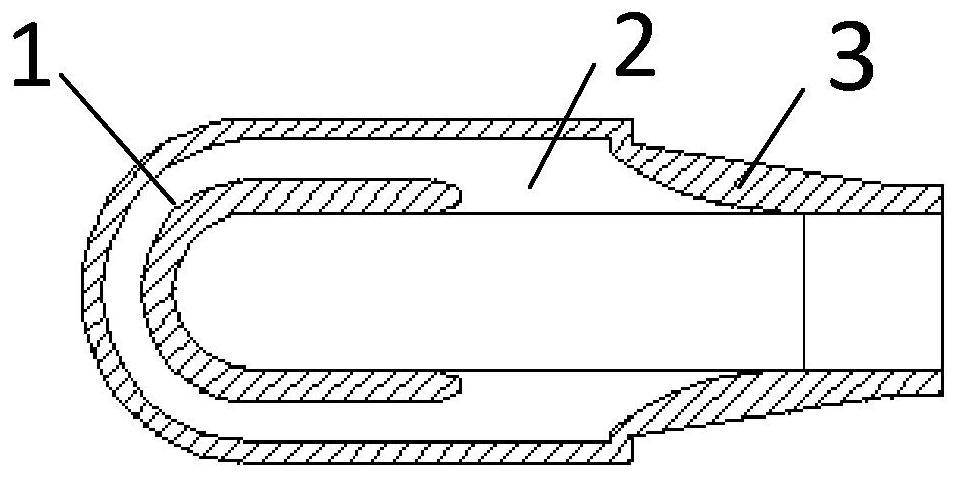

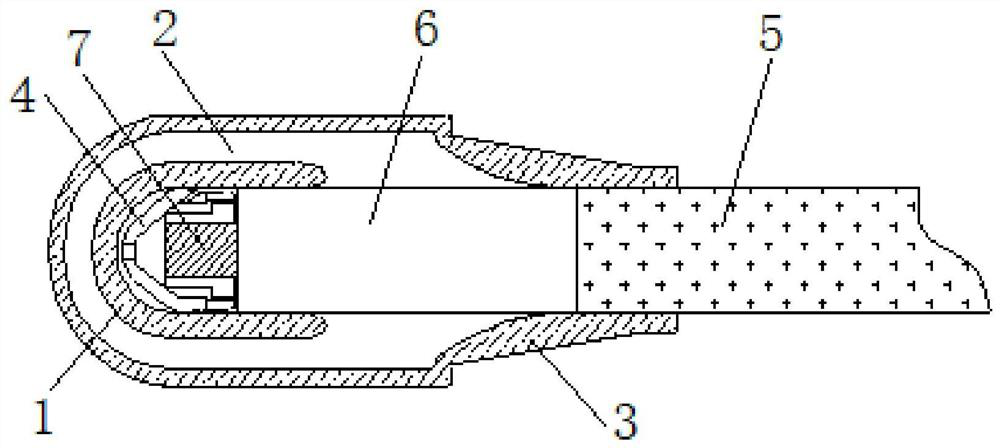

[0023] Such as figure 1 with figure 2 As shown, an insulated closed terminal of a power cable according to the present invention includes an inner shielding layer 1 , an insulating layer 2 , an outer shielding layer 3 and a metal shielding cover 4 . The inner shielding layer 1 and the outer shielding layer 3 are made of semi-conductive rubber material, and the insulating layer 2 is made of insulating rubber material. These three parts form an integral part through the rubber injection process and become the main body of the cable closed insulation terminal. The outer shielding layer 3 , insulating layer 2 and inner shielding layer 1 are sequentially arranged from outside to inside to form a semi-closed structure with one end open.

[0024] The metal shield 4 is a matching part. The metal shield 4 is set on the cable conductor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com