Preparing method of konjak coarse cereal rice

A production method and konjac technology are applied in the field of food processing to achieve the effects of adjusting dietary structure, retaining nutritional value and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

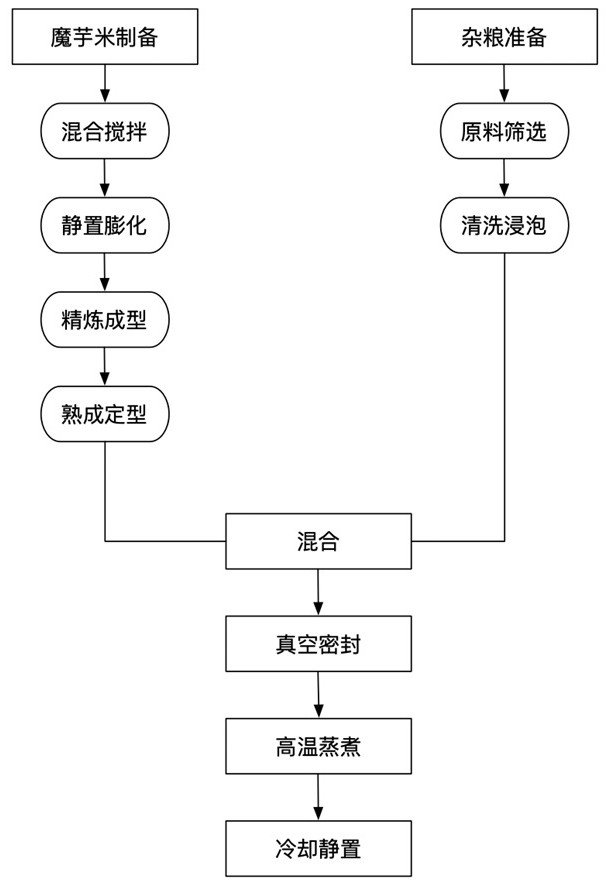

[0030] Embodiment 1: as figure 1 Shown, the invention discloses a kind of preparation method of konjac miscellaneous grain rice, the preparation method of this konjac miscellaneous grain rice specifically comprises the following steps:

[0031] (1) Preparation of konjac rice: Add konjac powder and water into water at 20°C in a ratio of 1:30, stir until fully dissolved; let stand for 1.5 hours to make the material expand into a paste slurry; put the paste slurry After fully mixing with the curing agent containing calcium ions through the refining agent, the shape of rice grains is obtained by extruding or shearing through a molding machine; aging in flowing hot water above 75°C to form a thermally irreversible gel and become rice grains Konjac gel food Konjac rice, cooled and rinsed, drained and set aside.

[0032] (2) Preparation of miscellaneous grains: the oats and barley are selected and the surface impurities are washed with water; soak the oats and barley in water for 1 ...

Embodiment 2

[0034] Embodiment 2: the present invention discloses a kind of preparation method of konjac miscellaneous grain rice, and the preparation method of this konjac miscellaneous grain rice specifically comprises the following steps:

[0035] (1) Preparation of konjac rice: add konjac powder and water into water at 21°C in a ratio of 1:28, stir until fully dissolved; let the material puff into a paste after standing for 2 hours; mix the paste The body and the curing agent containing calcium ions are fully mixed through the refining agent, and then the shape of rice grains is obtained by extruding or shearing through a molding machine; aging in flowing hot water above 75 ° C to form a thermally irreversible gel and become rice grains Konjac Gel Food Konjac Rice; cool, rinse and drain.

[0036] (2) Preparation of miscellaneous grains: After the oats are selected and the surface impurities are washed with clean water, the oats are soaked in hot water at 50°C for 1 hour and then draine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com