Flue gas desulfurization and denitrification device lower sliding support capable of accelerating progress

A technology of desulfurization and denitrification, sliding bearings, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of affecting the service life of sliding seats, increasing the number of lubricating oil additions, and wasting lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

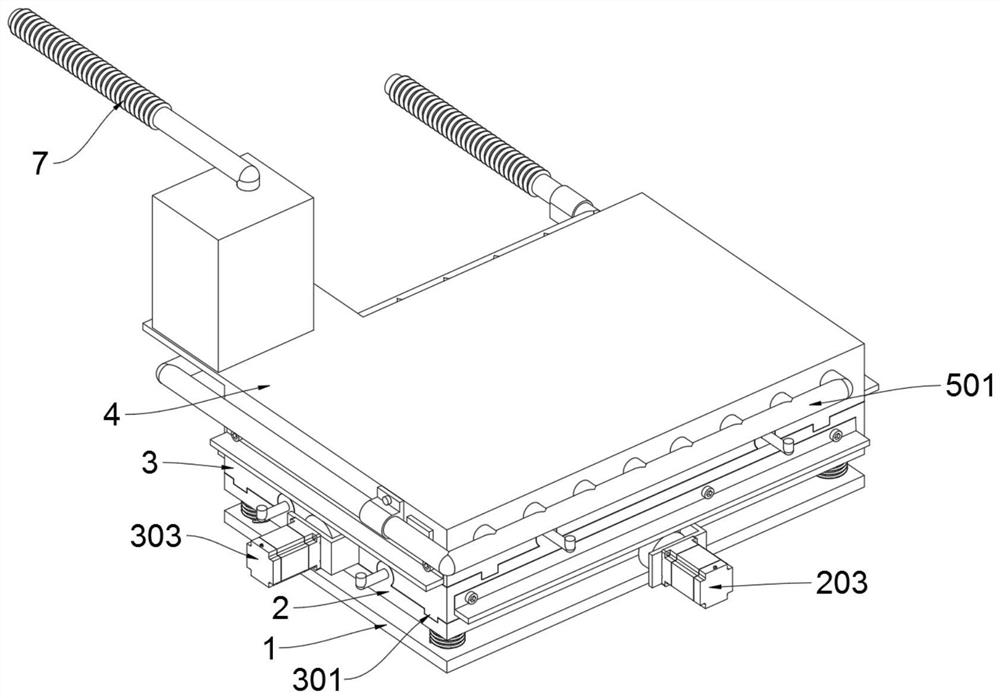

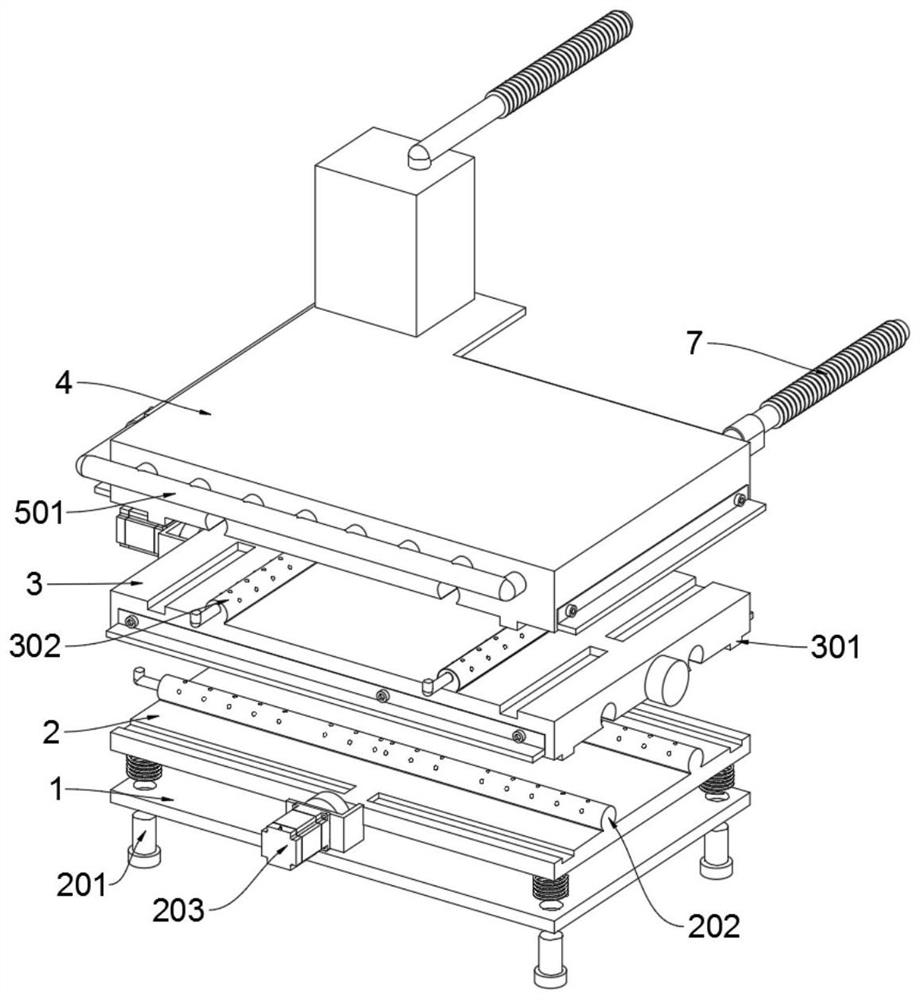

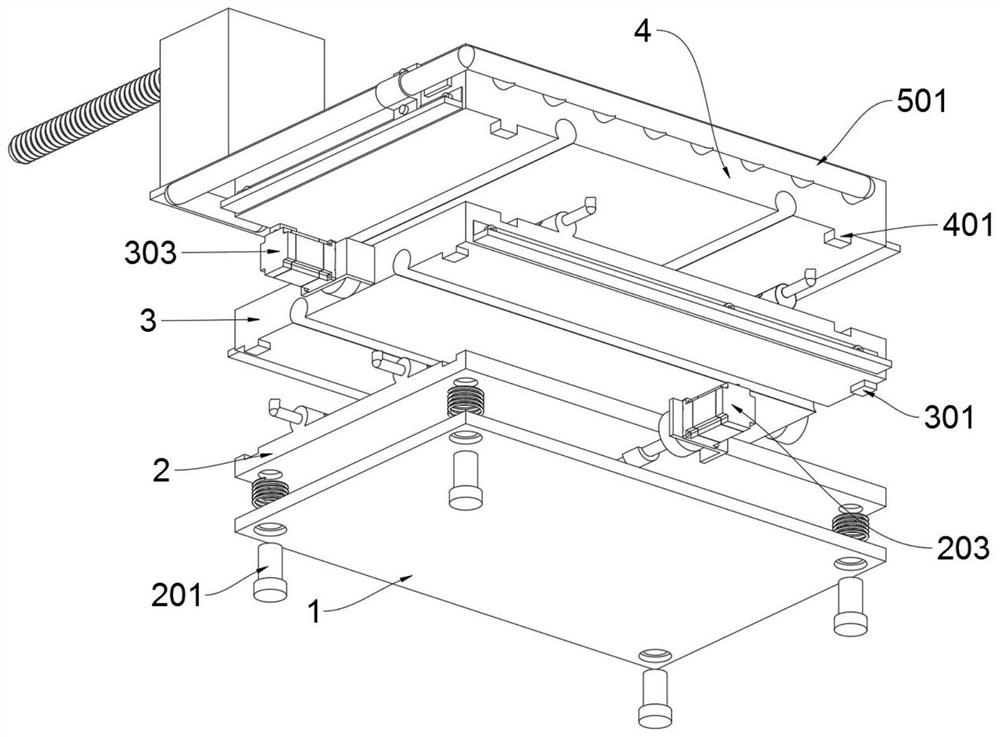

[0033] as attached figure 1 to attach Figure 7 Shown:

[0034]The present invention provides a sliding support for the lower part of a flue gas desulfurization and denitrification device that speeds up the progress, including a bottom plate 1; a support seat 2 is installed on the bottom plate 1, and a sliding seat 3 is installed on the support seat 2; A mounting base 4, and a group of heat dissipation mechanisms 5 are installed on the mounting base 4, and a heat dissipation pipe 6 is provided on the heat dissipation mechanism 5; a heat dissipation box is installed on the heat dissipation pipe 6, and a rectangular protrusion is provided on the mounting base 4 to dissipate heat. The box is installed on the rectangular protrusion, and two telescopic tubes 7 are installed on the cooling mechanism 5; At one corner, the bottom of the support base 2 is provided with four threaded holes, and the limit rod 201 is provided with external threads. On the hole, the limit rod 201 is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com