Processing device for dewaxing fluid

A technology for processing equipment and wax removal water, which is applied to mixers with rotating stirring devices, transportation, packaging, and dissolution. It can solve problems such as uneven mixing, labor consumption, and reduced product production efficiency, so as to improve the mixing effect. The effect of speeding up the swing frequency and improving the stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

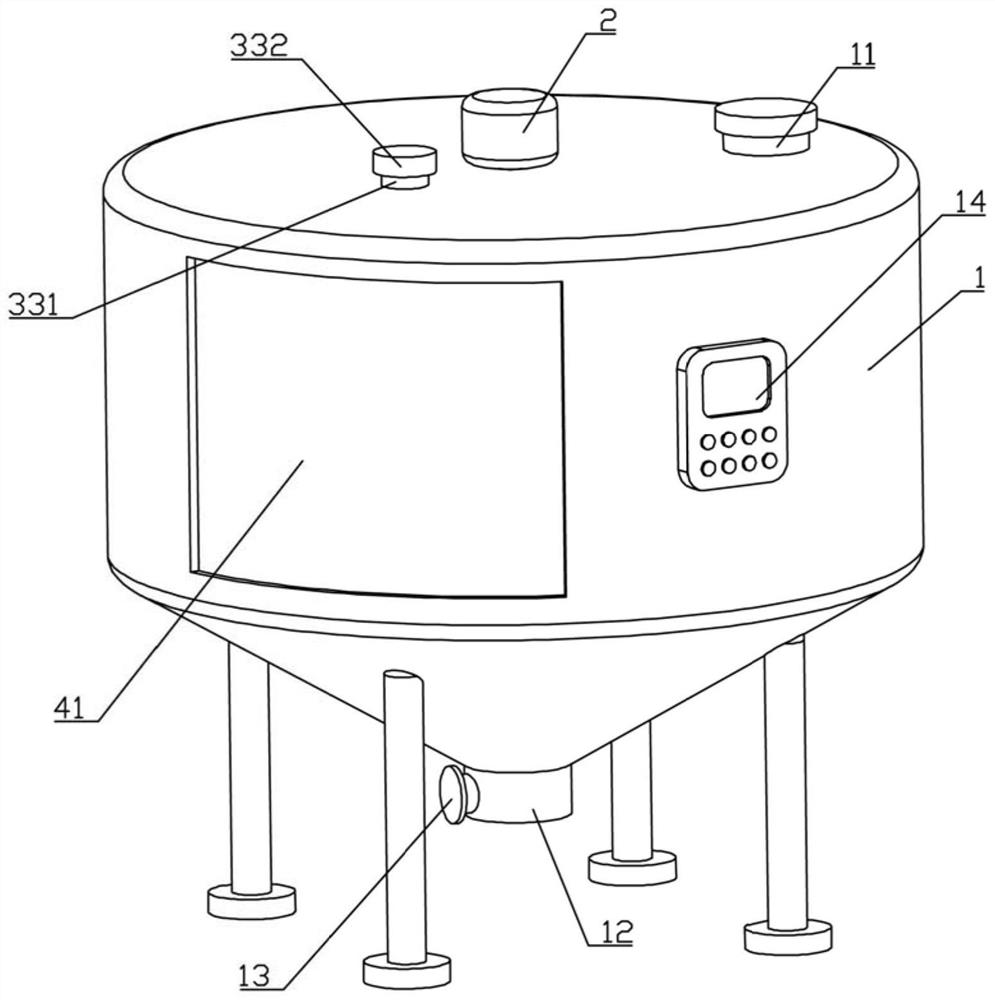

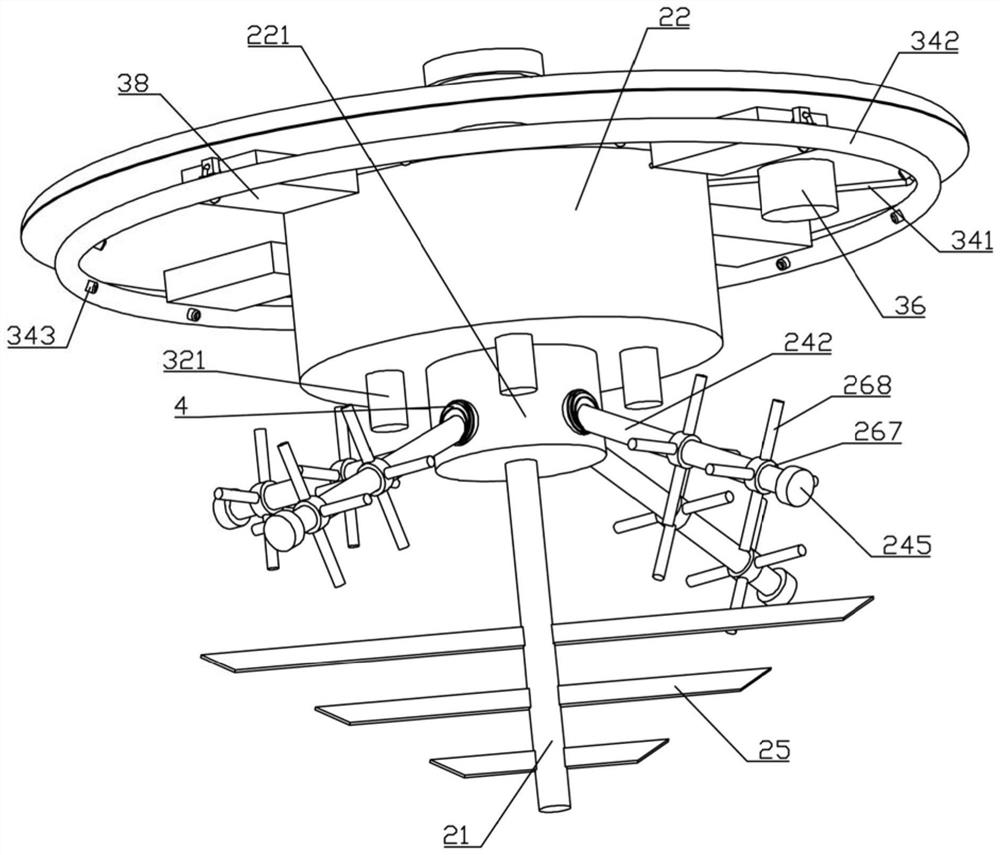

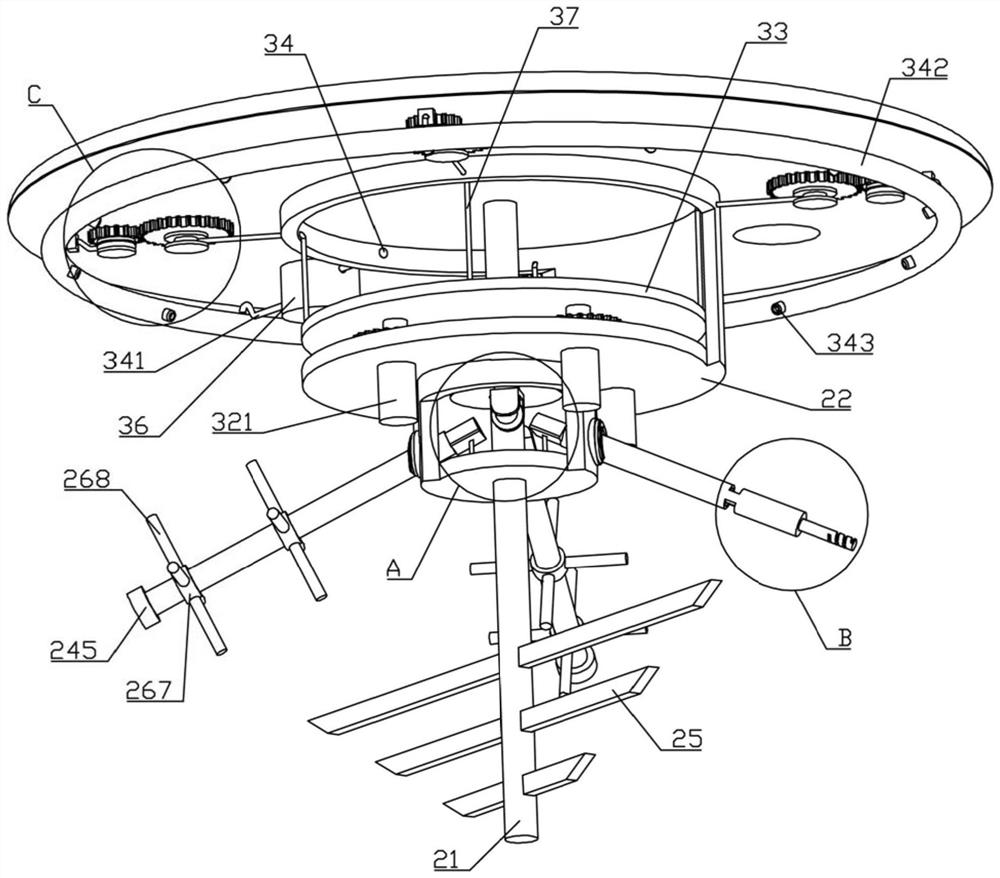

[0041] Such as Figure 1-16 As shown, a kind of processing device for wax removal water of the present invention comprises tank body 1, and tank body 1 is provided with feed port 11 and discharge port 12, and discharge port 12 is provided with electromagnetic valve 13, and tank body 1 There is a control panel 14, the solenoid valve 13 is electrically connected to the control panel 14, the control panel 14 is electrically connected to the external power supply, the upper middle part of the tank body 1 is provided with a motor 2, the motor 2 is electrically connected to the control panel 14, and the motor 2 The output shaft passes through the tank body 1 and is connected with a rotating shaft 21. The inner upper wall of the tank body 1 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com