Sludge circulation type high-efficiency hydrolysis reaction device

A technology of sludge circulation and hydrolysis reaction, applied in water/sludge/sewage treatment, biological treatment equipment, biological water/sewage treatment, etc., can solve the problem of long residence time, high requirements of water distribution system, weak impact load resistance, etc. problems, to achieve the effect of increasing sludge activity and concentration, increasing hydrolysis reaction rate, and saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

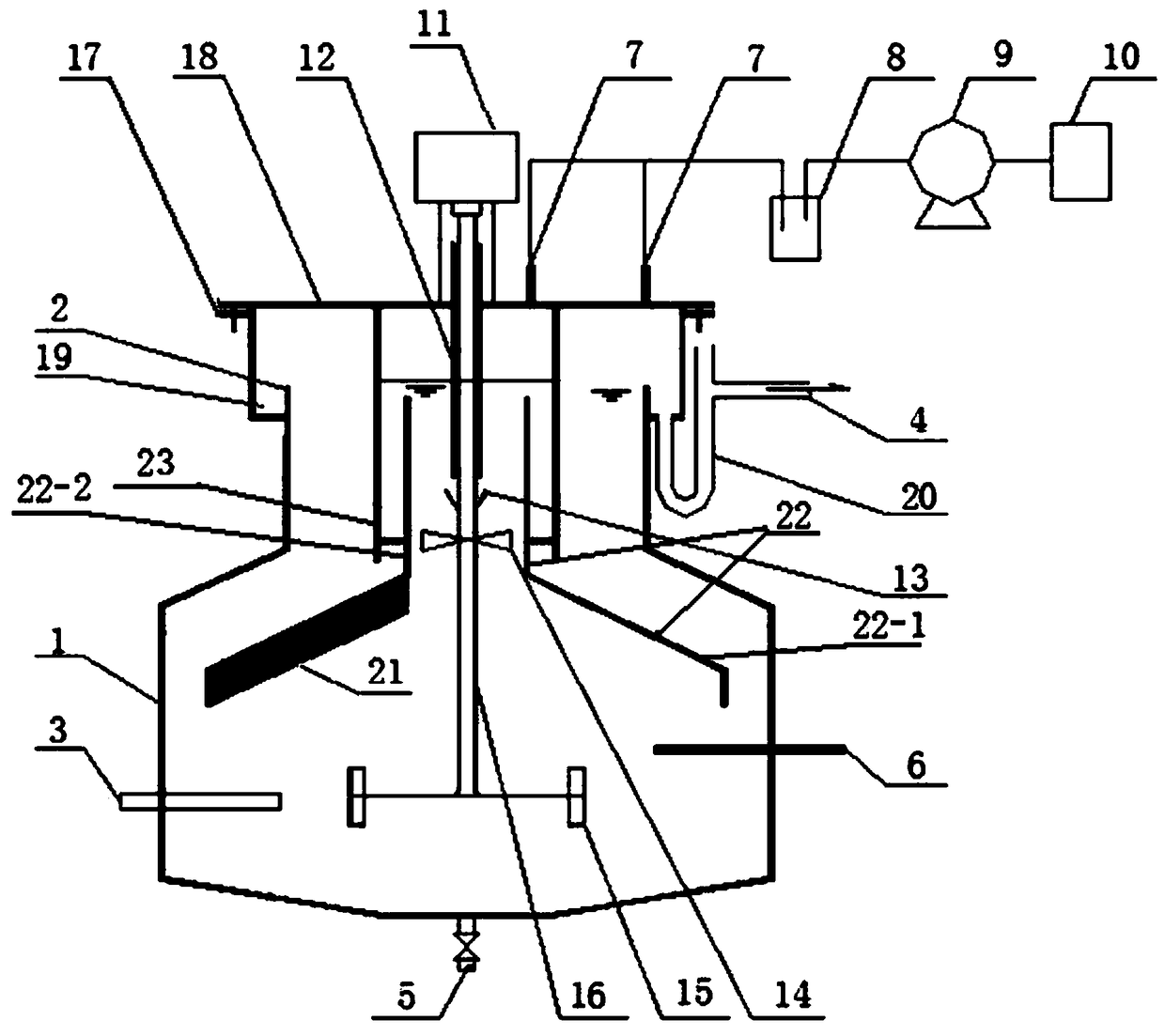

[0022] Specific implementation mode one: combine figure 1 , the sludge circulation type high-efficiency hydrolysis reaction device of the present embodiment is characterized in that it includes a tank body 1, a drainage weir 2, a water inlet 3, a water outlet 4, a sludge discharge pipe 5, a pH and ORP probe 6, exhaust pipe 7, water seal bottle 8, wet gas flow meter 9, gas online monitoring device 10, stirring motor 11, gas sealing tube 12, gas sealing baffle 13, propeller 14, stirring paddle 15, screw rod 16. Flange 17, top plate 18, sump 19, drain pipe 20 and diversion baffle 21;

[0023] The top of the pool body 1 is provided with a top plate 18, the gas sealing tube 12 runs through the top plate 18, the lower end of the screw rod 16 is located at the bottom of the pool body 1 and is connected to the stirring paddle 15, and the upper end of the screw rod 16 passes through the gas sealing tube 12 and is fixed on the stirring paddle. On the motor 11, the propeller 14 and the ...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the two exhaust pipes 7 are respectively arranged on the top plate 18 between the gas sealing pipe 12 and the vertical baffle 23, and the vertical baffle 23 On the top plate 18 between the pool body wall. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 in that: the umbrella-shaped support 22 and the bottom area of the cell body 1 together form a reaction zone. Others are the same as in the first embodiment.

[0030] The angle between the bottom of the reaction zone and the horizontal plane is 10°, so as to facilitate the regular sludge discharge after the reactor stops stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com