Dry anaerobic fermentation drying equipment of putrescible organic waste

A technology for dry anaerobic fermentation and organic waste, applied to biochemical equipment and methods, bioreactor/fermenter combinations, specific-purpose bioreactor/fermenter, etc., can solve the problem of long stirring time and difficult Uniform stirring, low stirring efficiency and other problems, to achieve uniform stirring, improve the effect of stirring, and improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

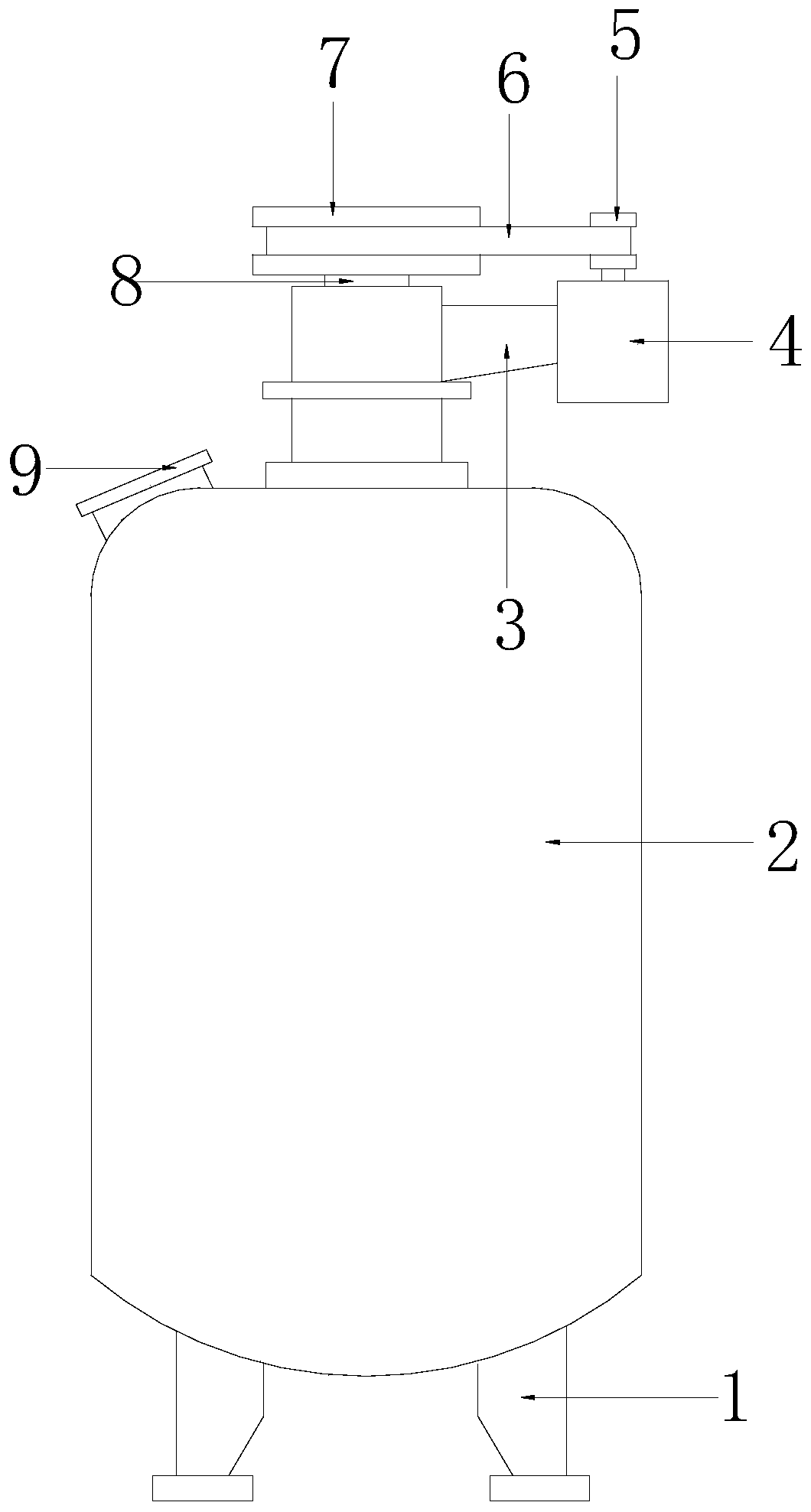

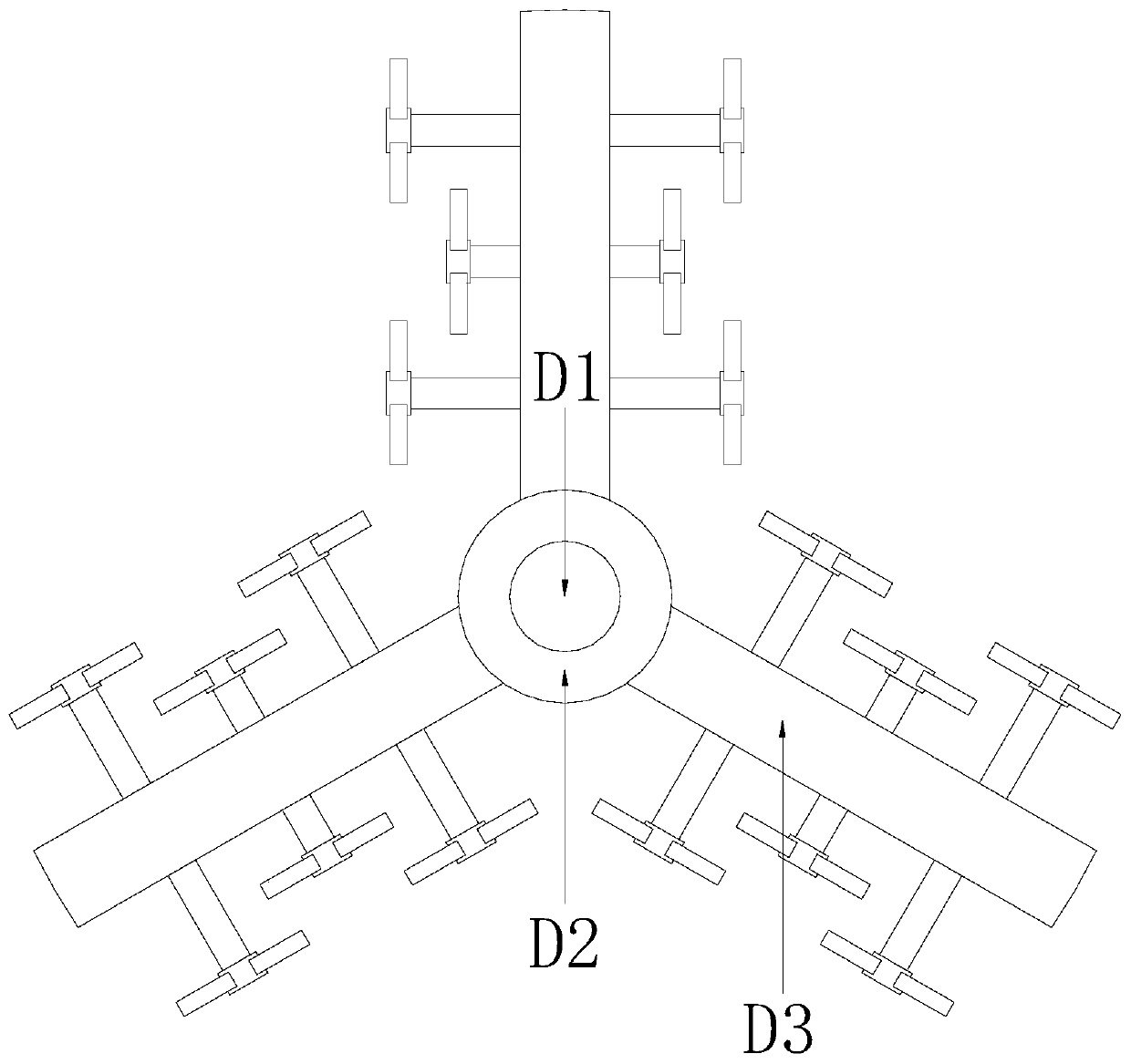

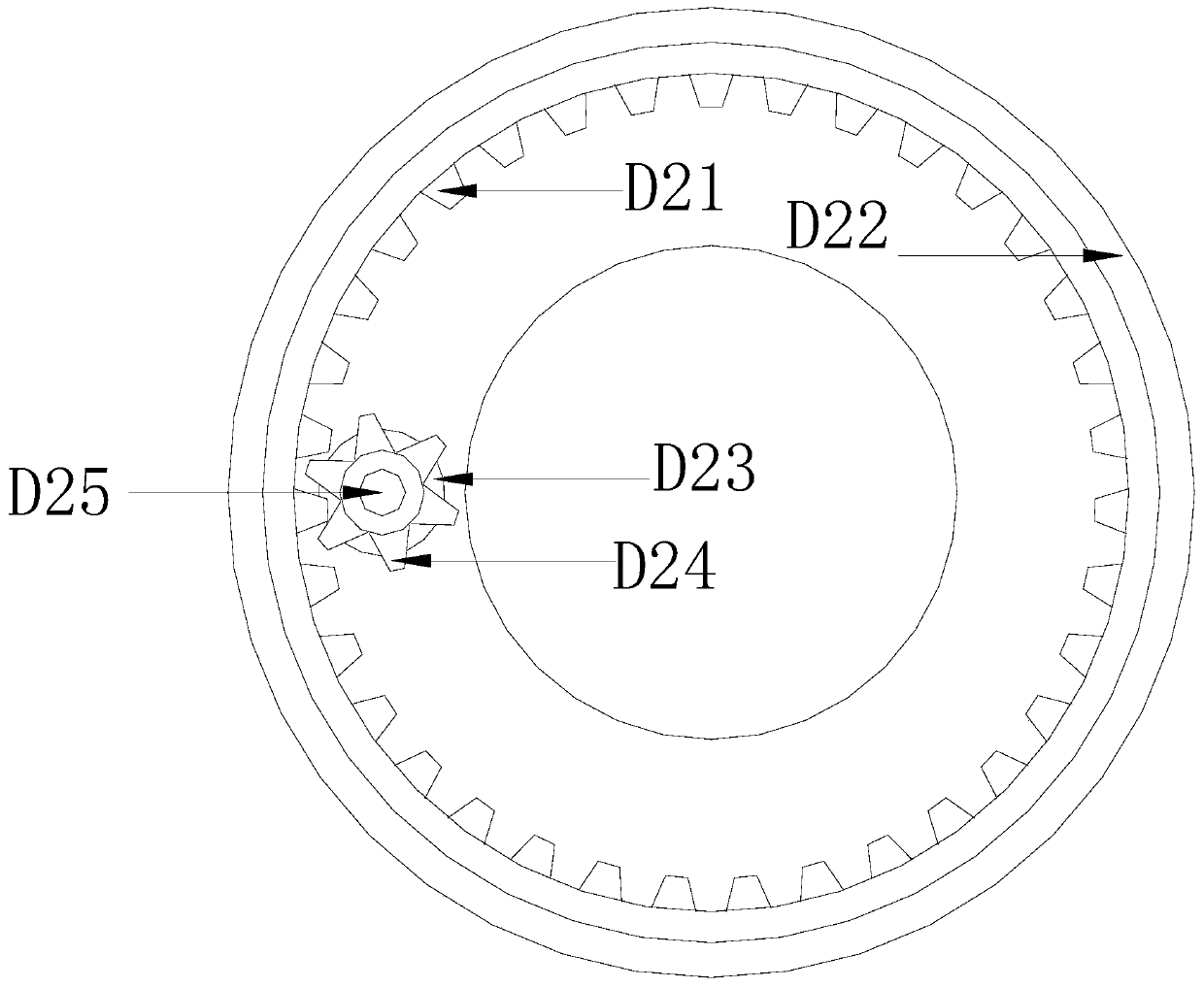

[0037] see Figure 1-8, the present invention provides a technical solution for dry-type anaerobic fermentation and drying equipment for perishable organic waste: its structure includes a foot 1, a dry-type anaerobic fermentation drying machine body 2, a shock absorber 3, and a high-efficiency and energy-saving motor 4 , driving wheel 5, transmission belt 6, driven wheel 7, horizontal and vertical stirring device 8, feeding hole 9, the bottom of the dry anaerobic fermentation drying machine body 2 is fixedly connected with a foot 1, and the top is equipped with a shock absorber 3, The shock absorber 3 is mechanically connected with a high-efficiency energy-saving motor 4, and the output shaft of the high-efficiency energy-saving motor 4 is equipped with a driving wheel 5, and the driving wheel 5 is connected with a driven wheel 7 through a transmission belt 6, and the driven wheel 7 is installed On the horizontal and vertical stirring device 8, the horizontal and vertical stir...

Embodiment 2

[0045] see Figure 1-10 , the present invention provides a technical solution for dry-type anaerobic fermentation and drying equipment for perishable organic waste: its structure includes a foot 1, a dry-type anaerobic fermentation drying machine body 2, a shock absorber 3, and a high-efficiency and energy-saving motor 4 , driving wheel 5, transmission belt 6, driven wheel 7, horizontal and vertical stirring device 8, feeding hole 9, the bottom of the dry anaerobic fermentation drying machine body 2 is fixedly connected with a foot 1, and the top is equipped with a shock absorber 3, The shock absorber 3 is mechanically connected with a high-efficiency energy-saving motor 4, and the output shaft of the high-efficiency energy-saving motor 4 is equipped with a driving wheel 5, and the driving wheel 5 is connected with a driven wheel 7 through a transmission belt 6, and the driven wheel 7 is installed On the horizontal and vertical stirring device 8, the horizontal and vertical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com