Aromatic lamp and manufacturing method thereof

A production method and aroma-type technology, applied in the field of aroma-type supply lamps and their production, can solve the problems of reducing bulge, low yield, large temperature difference, etc., to achieve rapid liquid level stabilization, ensure production quality, and avoid relative displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

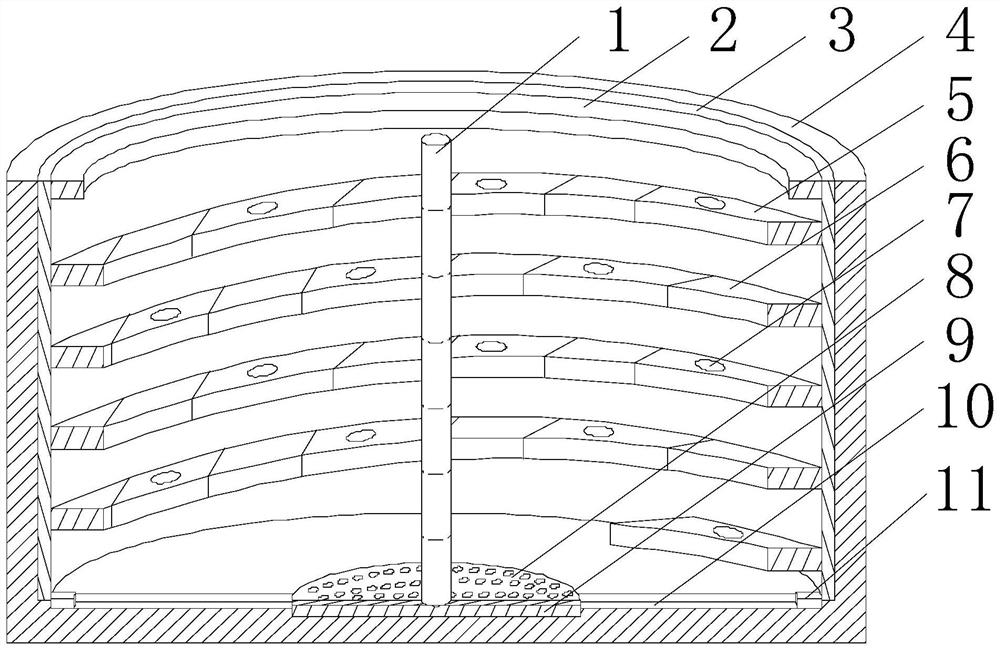

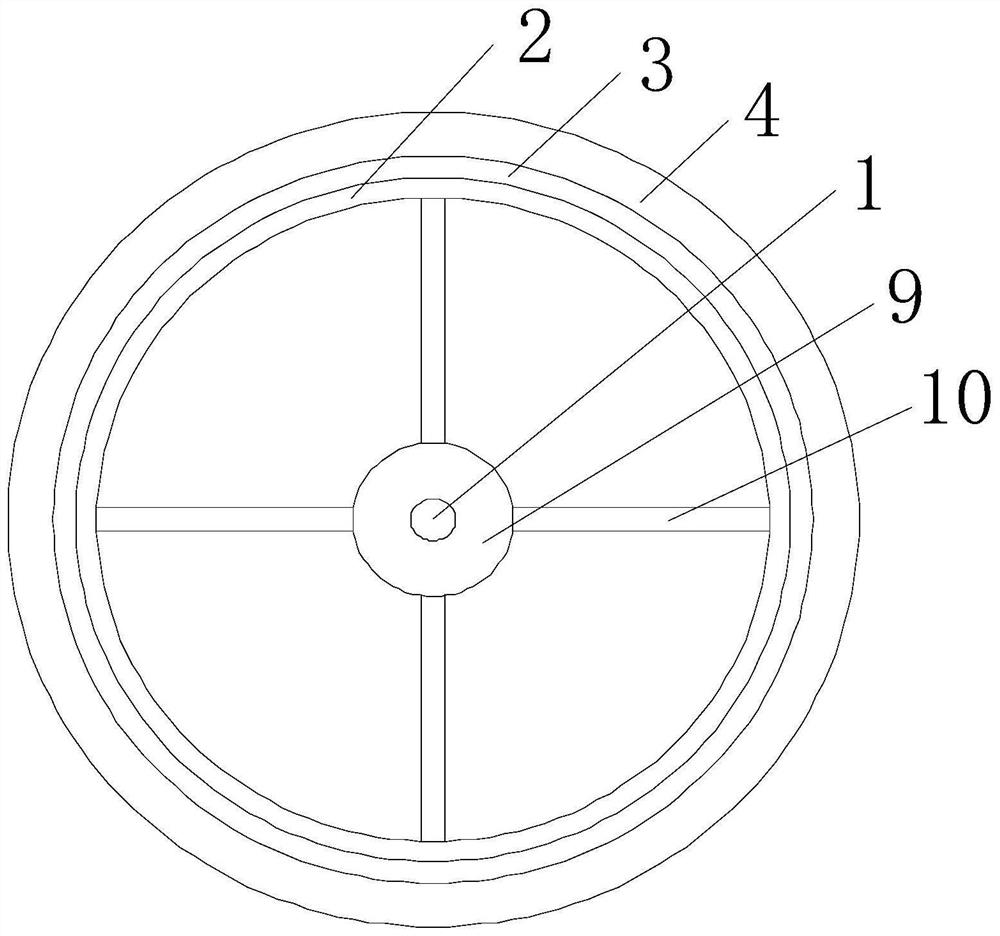

[0036] Such as figure 1 and figure 2 As shown, this embodiment includes a tank body 4, in which a matching inner sleeve 3 is provided, the two ends of the inner sleeve 3 are open, and the inner peripheral wall of the inner sleeve 3 is provided with There is a spiral body, a circular groove is opened in the middle part of the inner wall of the bottom of the axis of the tank body 4, the chassis 9 is placed in the circular groove, a wax core 1 is provided in the middle of the chassis 9, and a wax core 1 is provided in the middle of the inner sleeve 3 A retaining ring 2 is arranged on the inner wall of the upper section, and the inner sleeve 3 is filled with candle fuel.

[0037] During the specific operation, at first the chassis 9 and the wax core 1 are fixed in the circular groove, the inner sleeve 3 is placed in the tank body 4, and the outer peripheral wall of the inner sleeve 3 is closely attached to the inner wall of the tank body 4, and then the Fluid candle fuel is pou...

Embodiment 2

[0040] Such as figure 1 and figure 2 As shown, this embodiment is based on Embodiment 1. The spiral body includes a plurality of rotating plates 5 equidistantly distributed along the helix, and two adjacent rotating plates 5 are connected by a barrier plate 6. The plate 5 is made of metal material, and the barrier plate 6 is made of heat-resistant and flame-retardant silica gel. The setting of the spiral body can not only limit the candle fuel during pouring, but also increase the contact area between the candle fuel and the inner sleeve 3 when the candle fuel is cooling, thereby reducing the probability of the candle tank 4 detaching; in this technical solution , the spiral body includes a plurality of rotating plates 5 and a plurality of blocking plates 6, and two adjacent rotating plates 5 are connected through the blocking plates 6, the materials of the rotating plates 5 and the blocking plates 6 are different, and the rotating plates 5 adopt heat-conducting metal mater...

Embodiment 3

[0044] Such as figure 1 and figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of cutting grooves are arranged at equidistant intervals along the axial direction of the wax core 1 on its outer wall, and the groove depth of the cutting grooves is as deep as that of the wax core 1 1 / 3 of the radius; when used in jar candles, the burning part of the wax wick 1 is prone to distortion, resulting in smaller flames or easy generation of black smoke, which affects the user experience. In this technical solution, the wax The core 1 is cut so that after the wax core 1 burns for a certain distance, the tip of the burnt wax core 1 can fall off automatically without manual trimming, and the groove depth of the cutting groove is one-third of the radius of the wax core 1. The wax core 1 can maintain its own toughness without affecting its normal combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com