An indium-doped molybdenum carbide nanoflower core-shell photocatalyst and its preparation and application

A technology of photocatalyst and core-shell structure, which is applied in the field of photocatalytic materials, can solve the problems of poor photocatalytic reduction performance, easy recombination of photogenerated carriers, and poor selectivity of reduction products, achieving high CO2 reduction performance, low cost, and low cost. Effect of photogenerated electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing an indium-doped molybdenum carbide nanoflower core-shell structure photocatalyst, comprising the following steps:

[0045] (1) Take MoCl 5 and 2-methylimidazole were respectively dissolved in a mixed solvent of ethanol and methanol, and then mixed and stirred to obtain a Mo LDH precursor solution;

[0046] (2) Add InCl to the Mo LDH precursor solution 3 , react, separate, wash, and dry to obtain an In-doped MoLDH precursor;

[0047] (3) Calcining the In-doped Mo LDH precursor to obtain the target product.

[0048] In some embodiments, in step (1), MoCl 5 The concentration of the solution obtained by dispersing into the mixed solvent is preferably 0.48mmol / ml, and the concentration of the solution obtained by dispersing 2-methylimidazole into the mixed solvent is preferably 0.48mmol / ml. More preferably, when mixing and stirring, the 2-methylimidazole solution is added dropwise to the MoCl 5 In the solution, during the dr...

Embodiment 1

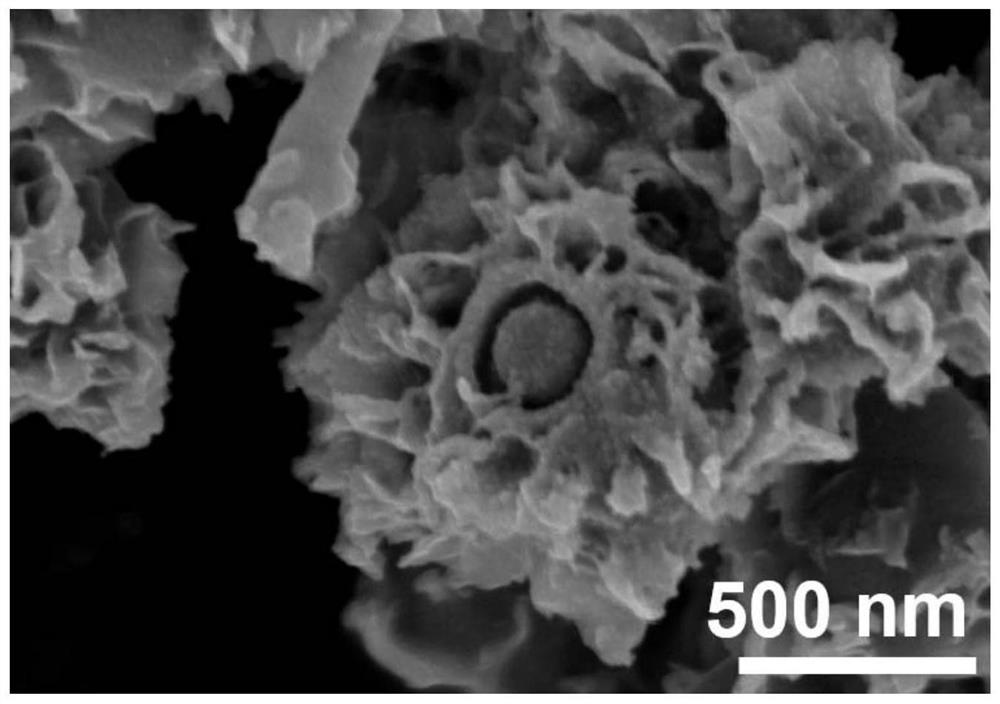

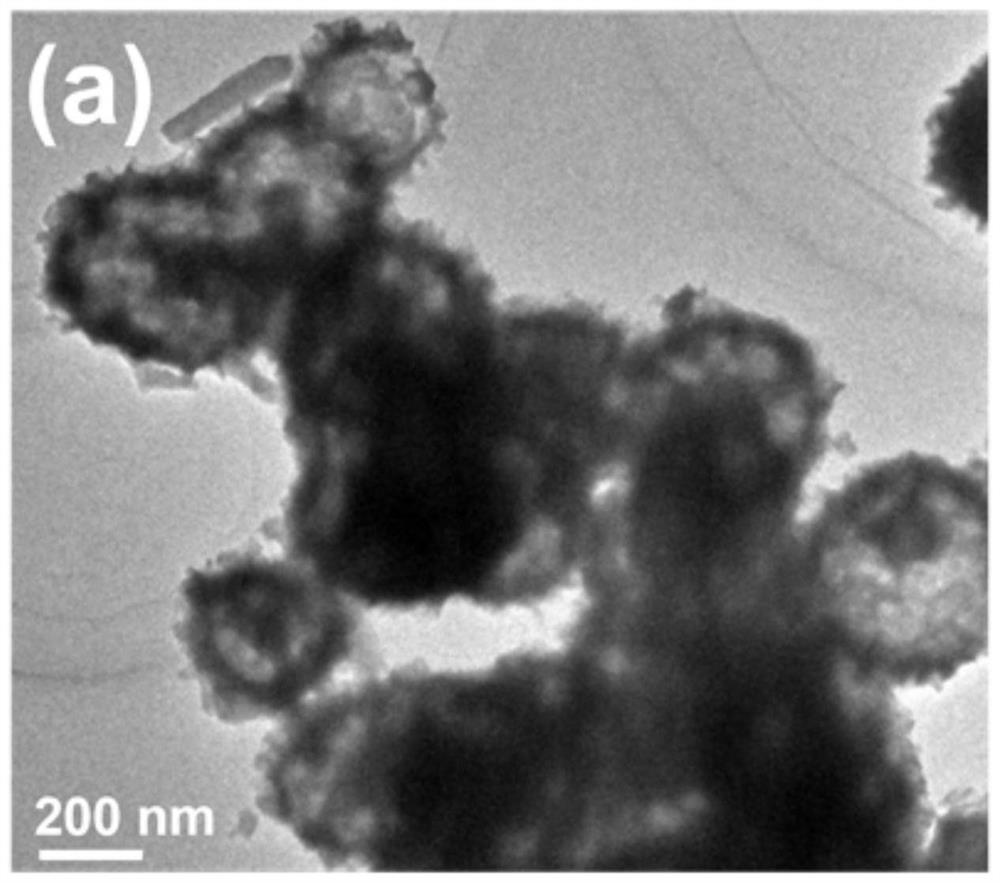

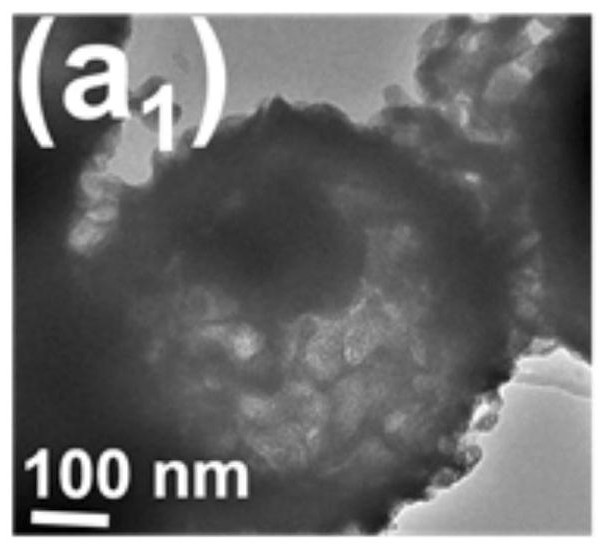

[0092] A defect-rich indium-doped molybdenum carbide nanoflower core-shell structure photocatalyst mainly contains five main elements of In, Mo, O, C, and N, and is prepared by a method comprising the following steps:

[0093] (1) Preparation of Mo LDH

[0094] Take 0.41g MoCl respectively 5 and 1.32g of 2-methylimidazole were dissolved in 40mL of a mixed solution of ethanol and methanol, wherein the volume ratio of ethanol to methanol was 1:1, and the 2-methylimidazole solution was added dropwise to MoCl 5 In the solution, the dropping rate was controlled to be 0.5ml / min.

[0095] (2) Preparation of In@Mo LDH

[0096] Add 0.25 mmol of indium trichloride tetrahydrate to the Mo LDH turbid solution in step (1), and obtain In@Mo LDH by ion exchange method. After stirring for 12 hours, centrifuge with ethanol, wash and dry to obtain In@Mo LDH , where the rotational speed was controlled at 8000r / min for 10min, the obtained precipitate was washed with absolute ethanol at a contro...

Embodiment 2

[0117] A defect-rich indium-doped molybdenum carbide nanoflower core-shell structure photocatalyst mainly contains five main elements of In, Mo, O, C, and N, and is prepared by a method comprising the following steps:

[0118] (1) Preparation of Mo LDH

[0119] Take 0.41g MoCl respectively 5 and 1.32g of 2-methylimidazole were dissolved in 40mL of a mixed solution of ethanol and methanol, wherein the volume ratio of ethanol to methanol was 1:1, and the 2-methylimidazole solution was added dropwise to MoCl 5 In the solution, the dropping rate was controlled to be 0.5ml / min.

[0120] (2) Preparation of In@Mo LDH

[0121] Add 0.5 mmol of indium trichloride tetrahydrate to the Mo LDH turbid solution in step (1), and obtain In@Mo LDH by ion exchange method. After stirring for 12 hours, centrifuge with ethanol, wash and dry to obtain In@Mo LDH , where the rotational speed was controlled at 8000r / min for 10min, the obtained precipitate was washed with absolute ethanol at a control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com