Bismuth metal loaded tungsten nitride photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and bismuth metal, which is applied in the field of photocatalytic materials, can solve problems such as insufficiency, and achieve the effects of promoting utilization, good hydrogen evolution cycle stability, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A bismuth metal-supported tungsten nitride photocatalyst mainly contains three main elements of Bi, W and N, and is prepared by a method comprising the following steps:

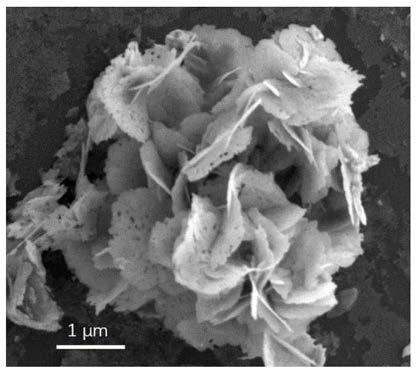

[0081] (1) Preparation of sheet-like WN (tungsten nitride nanosheets)

[0082] 288mg phosphotungstic acid (H 3 o 40 PW 12 .xH 2 O) In 50ml of deionized water, ultrasonically stirred for 10 minutes for 40 minutes; 15uL of pyridine was dissolved in 10ml of deionized water, and then slowly added to the above aqueous solution of phosphotungstic acid. Then the above solution was transferred to a 50°C oil bath and stirred for 24h, and finally centrifuged at 8000rpm, washed several times with deionized water and dried in an oven at 60°C to obtain a tungsten nitride precursor. The precursor was transferred to a tube furnace and calcined in an ammonia atmosphere at a calcination temperature of 600°C, a calcination time of 4 hours, and a heating rate of 3-5°C / min. Obtained flake WN.

[0083] (2), preparati...

Embodiment 2

[0101] A bismuth metal-supported tungsten nitride photocatalyst mainly contains three main elements of Bi, W and N, and is prepared by a method comprising the following steps:

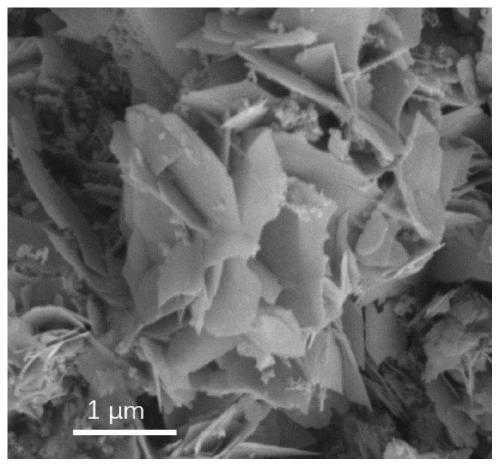

[0102] (1) Preparation of sheet-like WN (tungsten nitride nanosheets)

[0103] 300mg phosphotungstic acid (H 3 o 40 PW 12 .xH 2 O) In 50ml of deionized water, ultrasonically stirred for 10 minutes for 40 minutes; 10uL of pyridine was dissolved in 10ml of deionized water, and then slowly added to the above aqueous solution of phosphotungstic acid. Then the above solution was transferred to a 60°C oil bath and stirred for 12h, and finally centrifuged at 7000rpm, washed several times with deionized water and dried in an oven at 70°C to obtain a tungsten nitride precursor. The precursor was transferred to a tube furnace and calcined in an ammonia atmosphere at a calcination temperature of 650°C, a calcination time of 2 hours, and a heating rate of 3-5°C / min. Obtained flake WN.

[0104] (2), preparati...

Embodiment 3

[0109] A bismuth metal-supported tungsten nitride photocatalyst mainly contains three main elements of Bi, W and N, and is prepared by a method comprising the following steps:

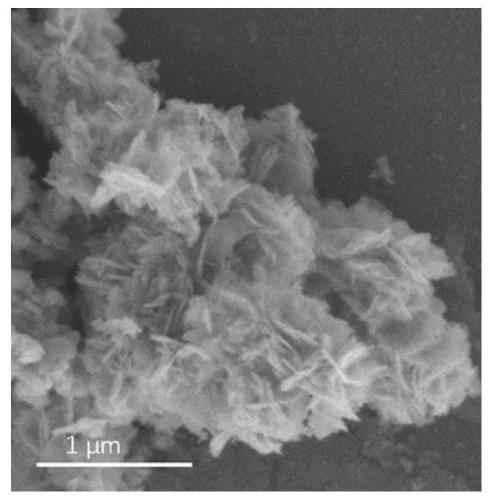

[0110] (1) Preparation of sheet-like WN (tungsten nitride nanosheets)

[0111] 250mg phosphotungstic acid (H 3 o 40 PW 12 .xH 2 O) In 50ml of deionized water, ultrasonically stirred for 10 minutes for 40 minutes; 20uL of pyridine was dissolved in 10ml of deionized water, and then slowly added to the above aqueous solution of phosphotungstic acid. Then the above solution was transferred to a 40°C oil bath and stirred for 48h, and finally centrifuged at 7500rpm, washed several times with deionized water and dried in an oven at 65°C to obtain a tungsten nitride precursor. The precursor was transferred to a tube furnace and calcined in an ammonia atmosphere at a calcination temperature of 550°C, a calcination time of 6 hours, and a heating rate of 3-5°C / min. Obtained flake WN.

[0112] (2), preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com