Special fixture for mounting high-speed camera of ultra-precision machine tool

A technology of ultra-precision machine tools and high-speed cameras, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve inconvenience and other problems, and achieve the effect of wide adjustment range, high adjustment accuracy and multiple adjustment angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

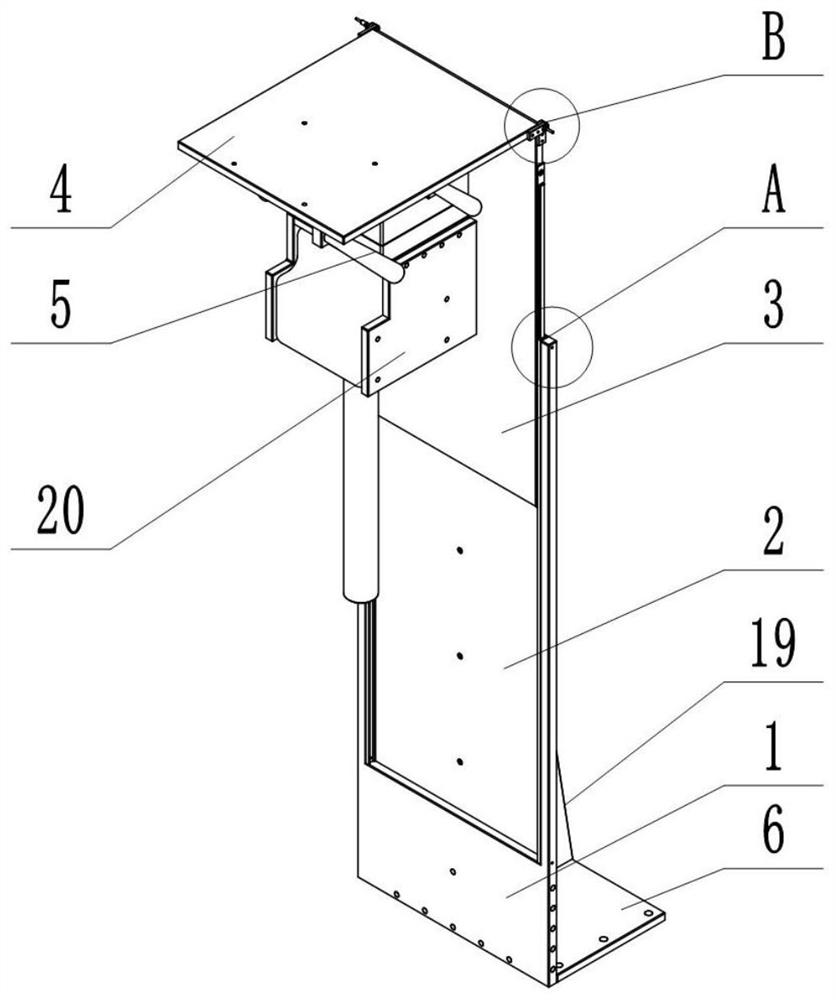

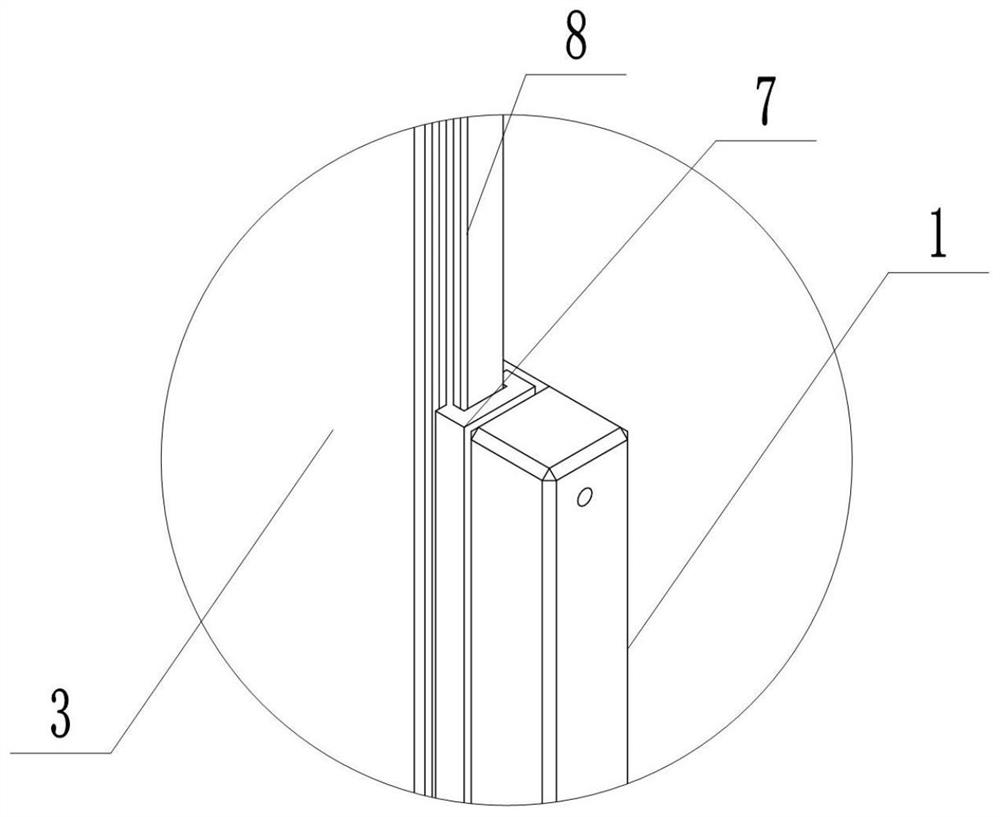

[0033] refer to Figure 1-6 , the present invention provides a special fixture for the installation of high-speed cameras for ultra-precision machine tools, including a lower vertical plate 1 of the fixture, a chute 2 is longitudinally opened on the top surface of the lower vertical plate 1 of the fixture, and an upper vertical plate of the fixture is slidably connected in the chute 2 3;

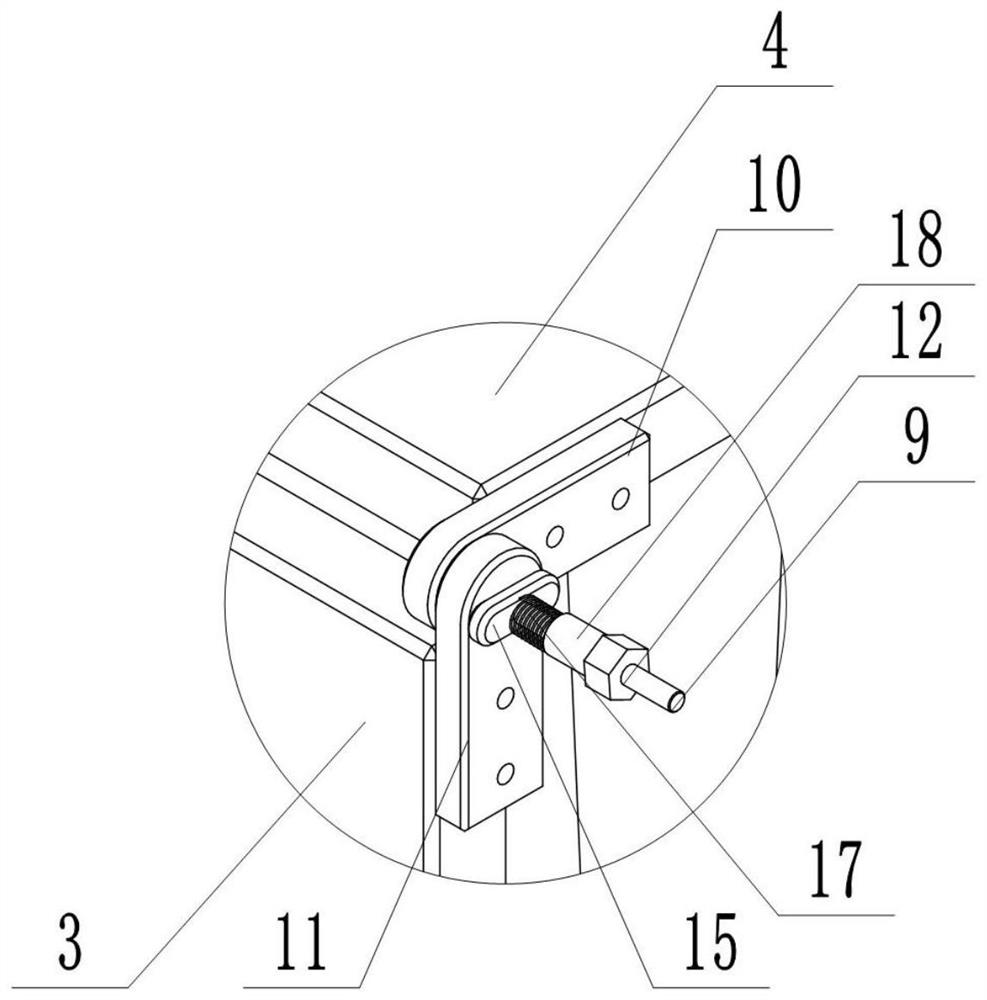

[0034] The top of the fixture upper vertical plate 3 is rotated to connect the fixture upper top plate 4, and a self-locking hinge assembly is arranged between the fixture upper vertical plate 3 and the fixture upper top plate 4;

[0035] A three-degree-of-freedom micro-displacement platform 5 is fixedly connected to one end surface of the upper top plate 4 of the fixture. The upper top plate 4 of the fixture is provided with a number of installation holes for fine-tuning the installation position of the three-degree-of-freedom micro-displacement platform 5. The three-degree-of-freedom micro...

Embodiment 2

[0048] refer to Figure 7 , the difference between this embodiment and Embodiment 1 is that the device is installed horizontally, the lower vertical plate 1 of the fixture is vertically fixed to the side of the additional base plate 21 of the clamp, and then the additional base plate 21 of the clamp is fixed with the high-speed machine tool, so that the device Horizontally installed and fixed; several screw holes are reserved on the upper vertical plate 3 of the fixture, and the three-degree-of-freedom micro-displacement platform 5 is fixed on the upper vertical plate 3 of the fixture, and the high-speed camera fixing frame 20 is installed with reference to the method of embodiment 1 here and high-speed cameras.

[0049] In this installation method, the adjustment method of the Z-axis direction is the same as that of the X-axis direction in Embodiment 1, the adjustment method of the X-axis direction is the same as that of the Z-axis direction in Embodiment 1, and the adjustmen...

Embodiment 3

[0052] refer to Figure 8-11 The difference between this embodiment and Embodiment 1 is that the lower vertical plate 11 of the fixture in this embodiment is provided with an inner shaft 22, the inner shaft 22 is located below the chute 2, and the inner shaft 22 is covered with two sections of outer shafts 26. The inner shaft 22 is rotationally connected with the outer shaft 26; two first bevel gears 27 are sleeved on the inner shaft 22, and a second bevel gear 28 is respectively sleeved on the two sections of the outer shaft 26, wherein the two first bevel gears The gears are respectively affixed to the inner shaft 22, and the two second bevel gears 28 are respectively affixed to the two sections of the outer shaft 26; two longitudinal screw rods 23 are arranged above the inner shaft 22, and a slider 25 is threadedly connected to the screw rod 23, The slider 25 is fixedly connected with the upper vertical plate 3 of the fixture; the end of the screw rod near the inner shaft 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap