Hydrophobic UV-LED ink for glass and preparation method thereof

A UV-LED, hydrophobic technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of poor adhesion, low weather resistance, general hydrophobicity, etc., achieve low cost, good adhesion, solve hydrophobicity general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a hydrophobic UV-LED ink for glass, comprising the following steps:

[0027] (1) Weigh each component according to the weight ratio in Table 1, mix and stir the silicone-modified urethane acrylate and urethane acrylate at 55°C, the stirring speed is 1000r / min, and the stirring time is 25 minutes;

[0028] (2) Continue to add n-vinyl caprolactam reactive diluent, photoinitiator, liquid polybutadiene, stirring speed 1000r / min, stirring time 60 minutes;

[0029] (3) Add fillers and additives, and stir at a stirring speed of 800r / min for 60 minutes;

[0030] (4) Fully grind on a three-roll machine until the ink fineness is below 5 microns.

Embodiment 2

[0032] A method for preparing a hydrophobic UV-LED ink for glass, comprising the following steps:

[0033] (1) Weigh each component according to the weight ratio in Table 1, mix and stir the silicone-modified urethane acrylate and urethane acrylate at 50°C, the stirring speed is 800r / min, and the stirring time is 20 minutes;

[0034] (2) Continue to add n-vinyl caprolactam reactive diluent, photoinitiator, liquid polybutadiene, stirring speed 1100r / min, stirring time 30 minutes;

[0035] (3) Add fillers and additives, and stir at a stirring speed of 900r / min for 80 minutes;

[0036] (4) Fully grind on a three-roll machine until the ink fineness is below 5 microns.

Embodiment 3

[0038] A method for preparing a hydrophobic UV-LED ink for glass, comprising the following steps:

[0039] (1) Weigh each component according to the weight ratio in Table 1, mix and stir the silicone-modified urethane acrylate and urethane acrylate at 60°C, the stirring speed is 900r / min, and the stirring time is 30 minutes;

[0040] (2) Continue to add n-vinyl caprolactam reactive diluent, photoinitiator, liquid polybutadiene, stirring speed 1200r / min, stirring time 50 minutes;

[0041] (3) Add fillers and additives, and stir at a stirring speed of 1000r / min for 100 minutes;

[0042] (4) Fully grind on a three-roll machine until the ink fineness is below 5 microns.

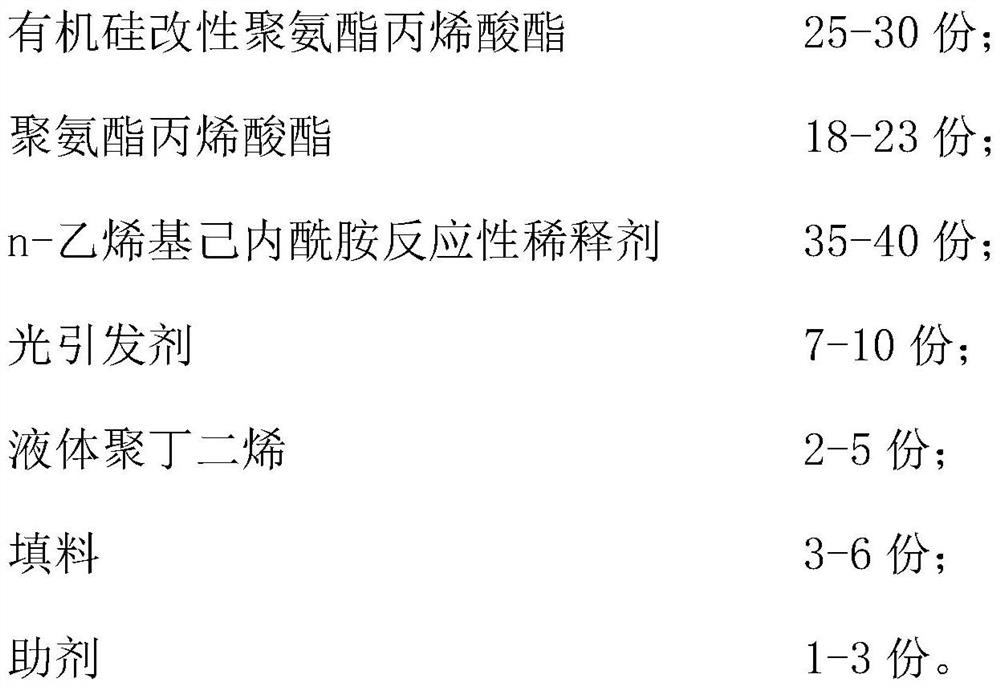

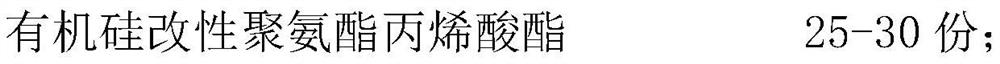

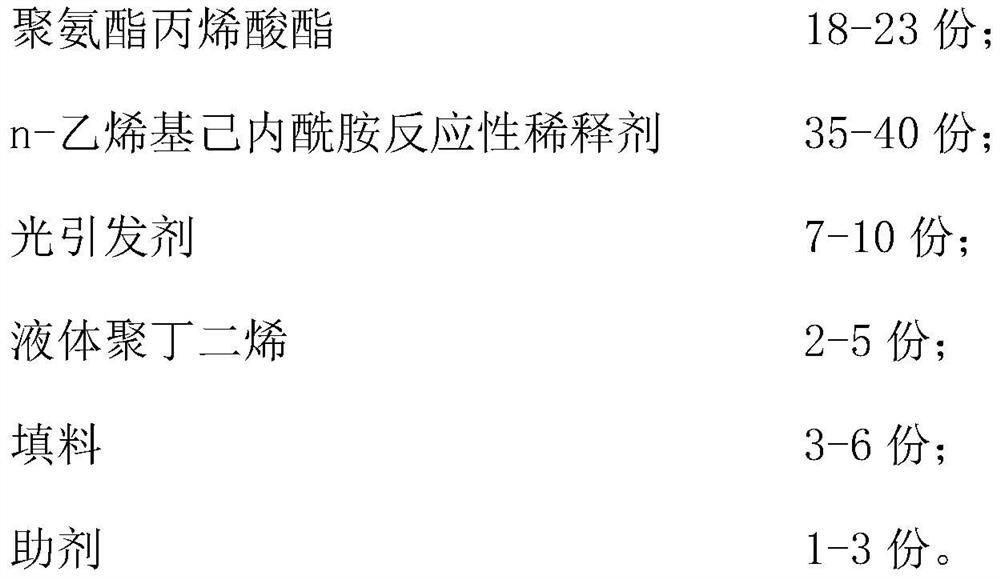

[0043] Table 1: The weight ratio of the UV-LED ink for glass of Examples 1-3

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com