Aluminum-rich high-entropy alloy and preparation method and application thereof

A high-entropy alloy and aluminum-rich technology, which is applied in the field of aluminum-rich high-entropy alloy and its preparation, can solve problems such as poor corrosion resistance and achieve excellent mechanical properties and good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

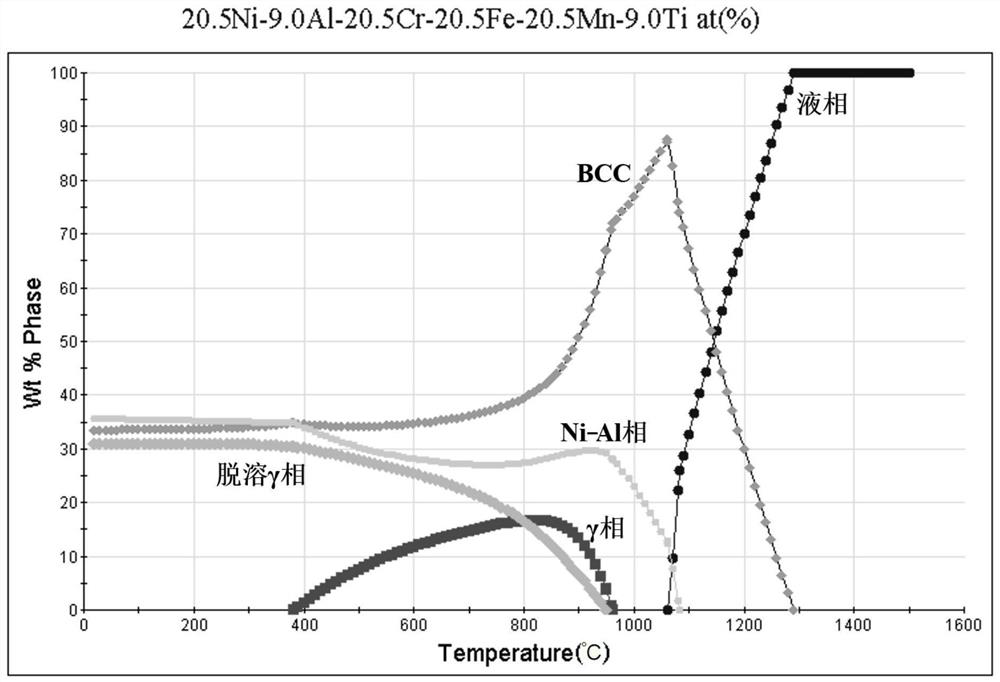

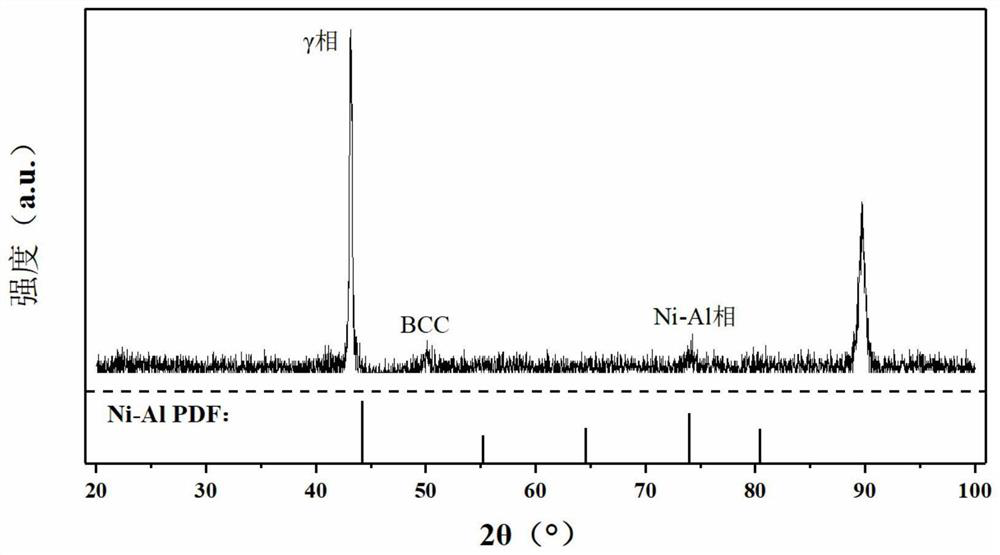

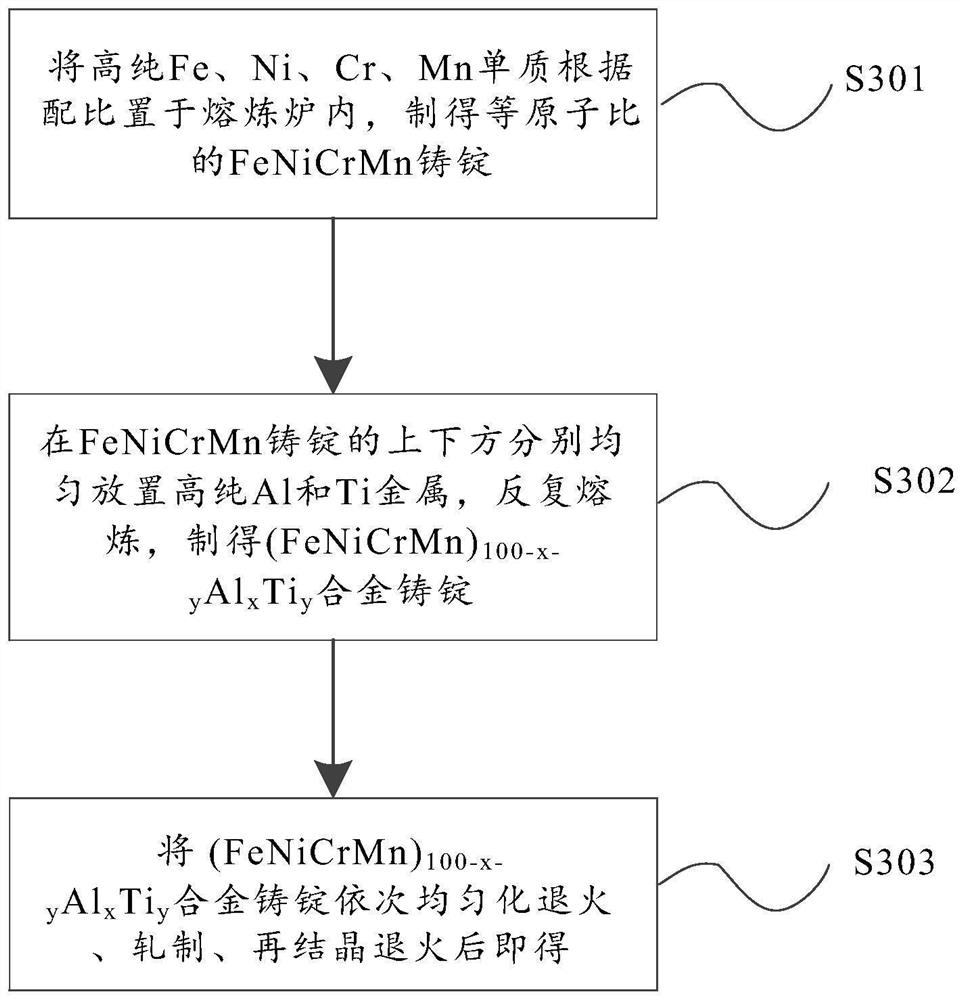

[0051] This embodiment prepares (FeNiCrMn) 82 al 9 Ti 9 Aluminum-rich high-entropy alloy, the equipment used is the vacuum suspension melting furnace of Shenzhen Saimet Company. Specific steps are as follows:

[0052] Put the high-purity Fe, Ni, Cr, and Mn elements into the melting furnace according to the ratio, and repeat the melting three times to obtain FeNiCrMn ingots with equiatomic ratios.

[0053] Place high-purity Al and Ti metals evenly on the top and bottom of the FeNiCrMn ingot, and repeat the melting three times to obtain (FeNiCrMn) 82 al 9 Ti 9 alloy ingot.

[0054] The (FeNiCrMn) 82 al 9 Ti 9 The alloy ingot was heated to 1150°C in a vacuum annealing furnace, homogenized and annealed for 14 hours, quenched in water and rapidly cooled to room temperature; then the above-mentioned homogenized annealed ingot was rolled to 65% of the thickness, and heated at 920°C Under recrystallization annealing for 2 hours, the finished alloy ingot is finally obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com