Underground continuous wall refining roundness connection structure and construction method thereof

A technology of underground diaphragm wall and connection structure, which is applied in basic structure engineering, excavation, sheet pile wall and other directions to achieve the effect of ensuring accuracy, facilitating subsequent cleaning and construction, and enhancing strength and connection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

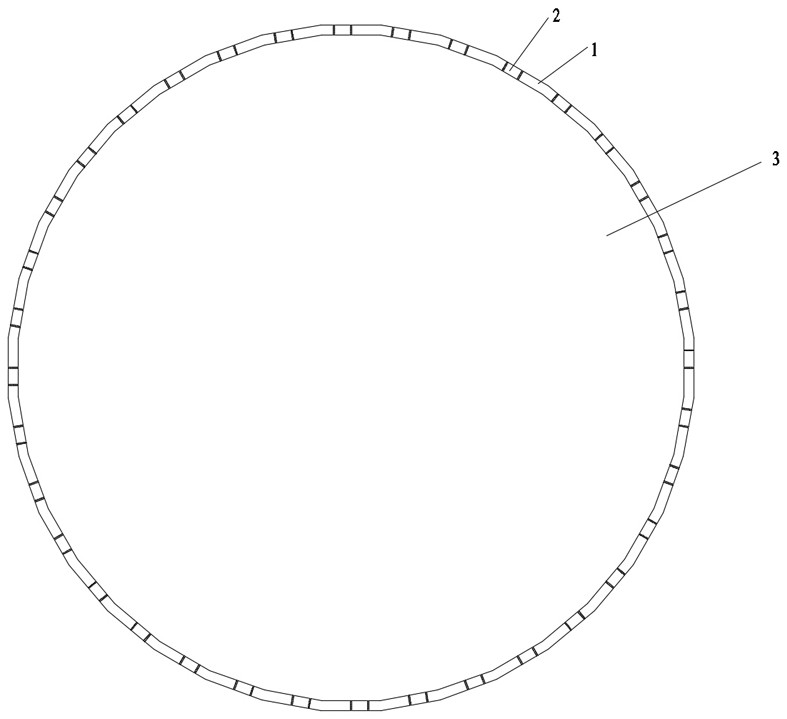

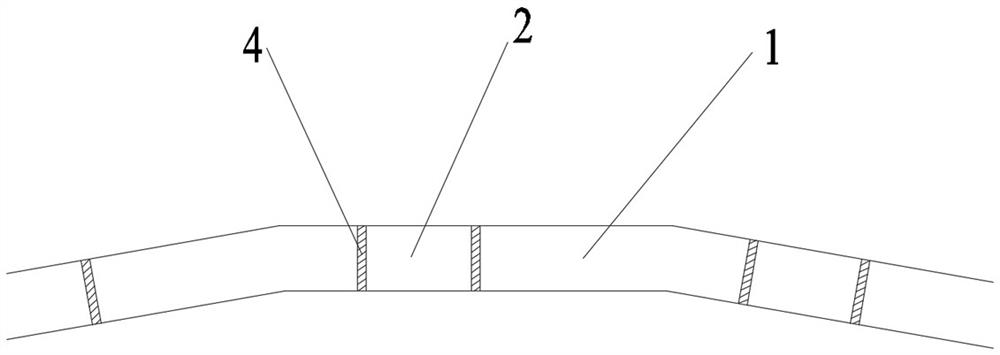

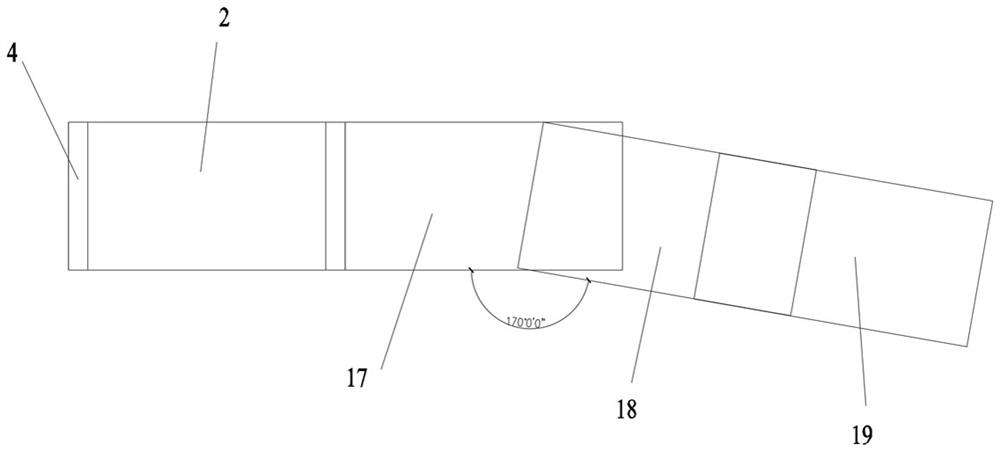

[0042] Taking a natural gas storage tank as an example, the underground structure floor of the storage tank is mainly located in medium and slightly weathered conglomerate and quartz porphyry. The 1.5m thick underground diaphragm wall is adopted, the depth is 53~61m, the concrete design strength grade is C45, and the impermeability grade is P12. Such as Figure 1 to Figure 5 As shown, the refined roundness connection structure of the underground diaphragm wall includes type I connecting wall 1, type II connecting wall 2 connected between adjacent type I connecting walls 1, and type I connecting wall 1 and type II connecting wall The casing milling section 4 arranged between the connecting walls 2; the type I connecting wall 1, the type II connecting wall 2 and the casing milling section 4 are connected in a ring shape, and the inside of the ring is the excavation surface 3; the type I connecting wall 1 and the type II connecting wall The 2 connecting walls are 36 pieces respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com