Bent-frame-free rapid construction method for high and steep slope support

A technology for high and steep slopes and construction methods, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as affecting the construction progress, long construction period, and affecting the overall stability of the slope, so as to improve construction efficiency and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

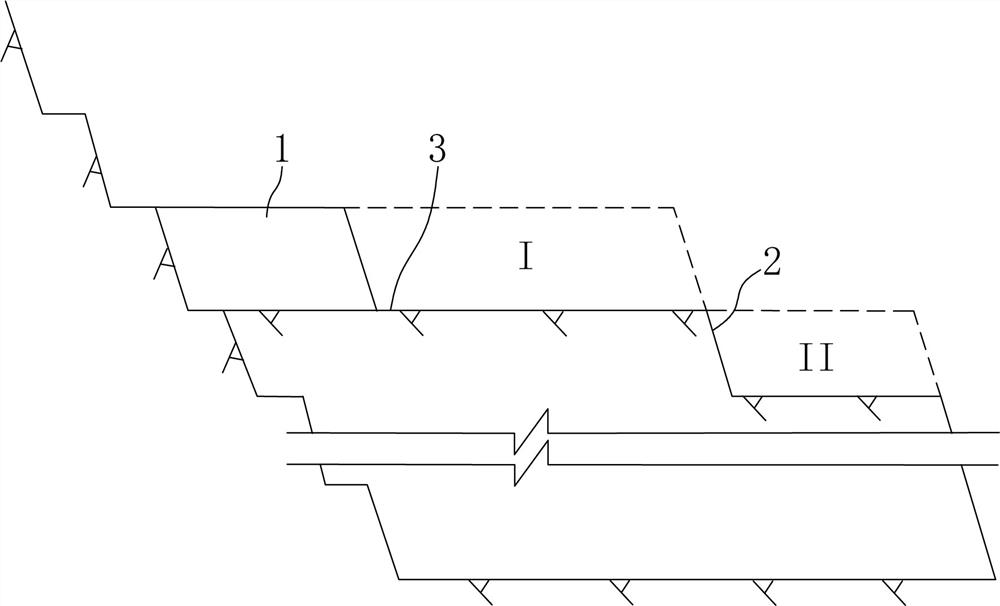

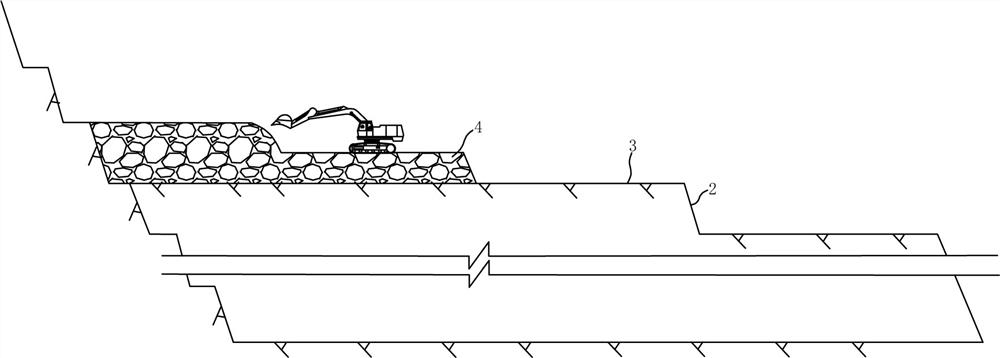

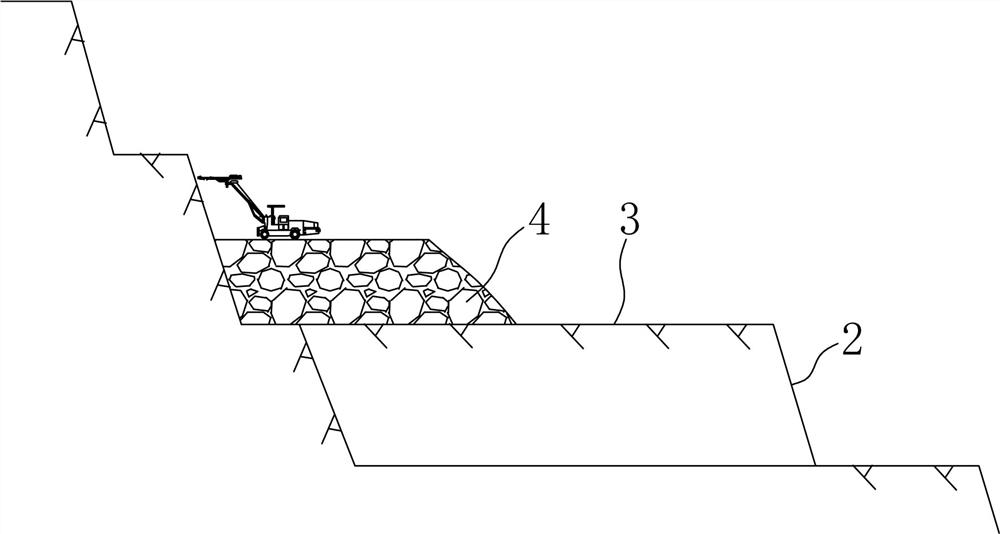

[0027] Such as Figure 1-4 Among them, a rapid construction method for high and steep slope support without bending, including the following steps:

[0028] 1) Reserve protective layer 1 at the slope position;

[0029] 2) The side slope is excavated in layers to the position of protective layer 1 and steps 2 are formed, and the excavation sequence is as follows figure 1 In the order of "I→II→...";

[0030] 3) Carry out blasting and excavation of the protective layer and form a support construction platform 3;

[0031] 4) Carry out support construction and spray concrete on the support construction platform 3;

[0032] 5) After completing the support construction of the previous step 2, repeat steps 2)-4) to carry out the construction of the next step 2.

Embodiment 2

[0034] In the step 3), the pre-splitting blast hole and the main blast hole are drilled with the CM351 high air pressure drilling rig, and the CM351 high air pressure drilling rig is used to replace the traditional YQ-100B drilling rig for the pre-split hole drilling. Since the CM351 drill The mechanical angle of the hole is difficult to control, and the hole diameter is large. Compared with the traditional pre-splitting blasting, the charge structure needs to be adjusted experimentally, which further increases the difficulty of pre-splitting blasting.

[0035] Weld a steel plate on the arm of the CM351 high air pressure drilling rig, dig a round hole with a diameter of 3cm on the steel plate, tie a hanging wire hammer in the hole, and the surveyors will fix the pre-splitting blast holes along the opening line of the pre-splitting holes and The location of the directional hole. Pre-split blast holes are marked with red paint or red plastic bags for hole location control.

[0...

Embodiment 3

[0038] On the basis of Example 2, after the pre-splitting hole is positioned, use a goniometer measuring tool to check the hole angle and direction accurately before drilling, and the drilling can only be started after the accuracy is correct.

[0039] Since each hole needs to be checked, the workload is heavy, and the side angle of the "special slope measuring instrument" is used. Press a steel plate on the boom frame of the CM351 drilling rig, and fix the "special slope measuring instrument" on the steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com