Self-adhesive sealing type drainage system

A drainage system and sealing technology, which is applied in the direction of roof drainage, roof insulation materials, fixed filter elements, etc., can solve the problems of increasing operating costs, increasing construction period, affecting the structure of houses, etc., and achieves elongation at break High, reduce the construction period, the effect of high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

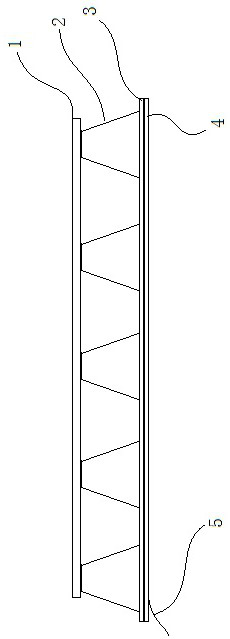

[0034] like figure 1 , Figure 6 to Figure 8 As shown, a self-adhesive sealed drainage system includes a drainage board structure and a siphon type drainage groove. The drainage board structure includes a base plate 3, several bosses 2, a filter layer 1, a waterproof layer 4 and a self-adhesive layer 5 , the plurality of bosses 2 are distributed on the substrate 3 in a matrix, the filter layer 1 is arranged above the bosses 2, one side of the waterproof layer 4 is connected to the bottom surface of the substrate 3, the The other side of the waterproof layer 4 is connected to the self-adhesive layer 5 .

[0035] The drainage board structure and the siphon type drainage groove are combined and spliced in any combination, and the joints between the drainage board structures, between the drainage board structure and the siphon type drainage groove, and between the siphon type drainage grooves are provided with waterproof Material.

[0036] In this embodiment, preferably, the ...

Embodiment 2

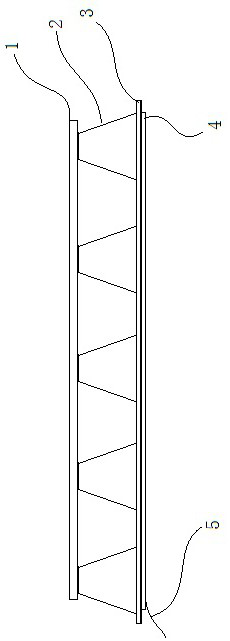

[0045] like figure 2 , Figure 6 to Figure 8 As shown, another self-adhesive sealed drainage system includes a drainage board structure and a siphon type drainage groove. The drainage board structure includes a base plate 3, several bosses 2, a filter layer 1, a waterproof layer 4 and a self-adhesive layer 5. The plurality of bosses 2 are distributed on the substrate 3 in a matrix, the filter layer 1 is arranged above the bosses 2, one side of the waterproof layer 4 is connected to the bottom surface of the substrate 3, and the The other side of the waterproof layer 4 is connected to the self-adhesive layer 5 .

[0046] The drainage board structure and the siphon type drainage groove are combined and spliced in any combination, and the joints between the drainage board structures, between the drainage board structure and the siphon type drainage groove, and between the siphon type drainage grooves are provided with waterproof Material.

[0047]In this embodiment, prefera...

Embodiment 3

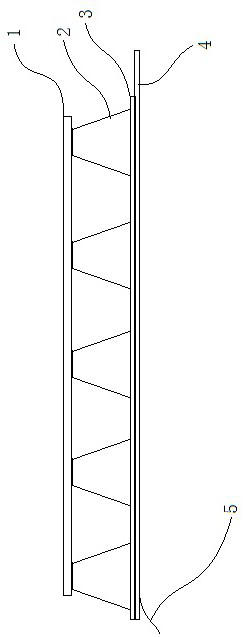

[0056] like image 3 , Figure 6 to Figure 8 As shown, another self-adhesive sealed drainage system includes a drainage board structure and a siphon type drainage groove. The drainage board structure includes a base plate 3, several bosses 2, a filter layer 1, a waterproof layer 4 and a self-adhesive layer 5. The plurality of bosses 2 are distributed on the substrate 3 in a matrix, the filter layer 1 is arranged above the bosses 2, one side of the waterproof layer 4 is connected to the bottom surface of the substrate 3, and the The other side of the waterproof layer 4 is connected to the self-adhesive layer 5 .

[0057] The drainage board structure and the siphon type drainage groove are combined and spliced in any combination, and the joints between the drainage board structures, between the drainage board structure and the siphon type drainage groove, and between the siphon type drainage grooves are provided with waterproof Material.

[0058] In this embodiment, prefera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com