Toughness detection device for cable processing

A detection device and cable technology, which is applied to measurement devices and uses a stable bending force to test the strength and strength characteristics of materials, can solve the problems of poor applicability, inconvenient use, bloated mechanism, etc., and achieve high bending efficiency and convenient use. , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

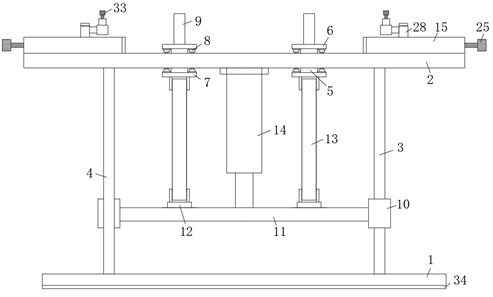

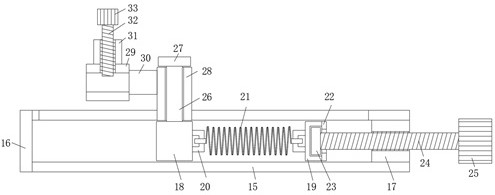

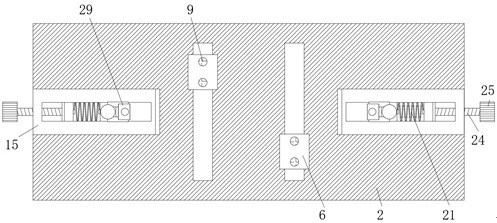

[0027] Refer Figure 1-4 A toughness detecting device for cable processing, including the base 1, and the bottom of the base 1 is provided with a detection table 2, and the bottom portion of the detecting table 2 is fixed to the base 1, and there is a track penetrating rod 3, or the track penetration rod 3 has two For the detecting table 2, there is a track long hole, and there are two orbital long holes and each other, and the track is slidably connected to the slider 5, and both ends of the slider 5 extend to the detection table 2. On the side and fixing the top side of the top plate 6 and the bottom plate 7, the top side of the top plate 6 is fixedly connected with two positioning rod 9, and the outer sliding sleeve of the rod portion of the track pendulum 3 is provided with a slider 10, and the two slider 10 is fixedly connected. There is a horizontal plate 11, and the top side of the cross plate 11 is fixedly connected to the connecting plate 12, and the connecting plate 12 is...

Embodiment 2

[0030] Such as Figure 1-4 As shown, the present embodiment is substantially identical, preferably, the base 1 and the detection table 2 are fixedly connected to the auxiliary support rod 4, and the auxiliary support rod 4 has two, two auxiliary support rods 4 and two tracks. The vertical rod 3 is a rectangular cross-distribution.

[0031] In this embodiment, the arrangement of the auxiliary support rod 4 is supported by the track penetration rod 3, so that the state of the detecting table 2 is more stable.

Embodiment 3

[0033] Such as Figure 1-4 As shown, the present embodiment is substantially the same as that, preferably, the top plate 6 and the bottom plate 7 are mounted on one side of the detection table 2, and the minus beads 8 are located on both sides of the orbital longifuane. On the side of the minus bead 8, the side of the detection table 2 scrolls the contact connection.

[0034] In the present embodiment, the arrangement of the devil bead 8 causes the slider 5, the top plate 6, and the bottom plate 7 more smoothly in the horizontal reciprocating movement, and reduces friction loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com