Gas condensation visualization and heat exchange characteristic detection device and method

A detection device, gas condensation technology, applied in the direction of measuring devices, material condensation, material thermal development, etc., can solve problems such as inaccurate flow control, thermocouple corrosion, equipment failure, etc., to enhance protection performance, ensure reliable and accurate work, Increases the effect of protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

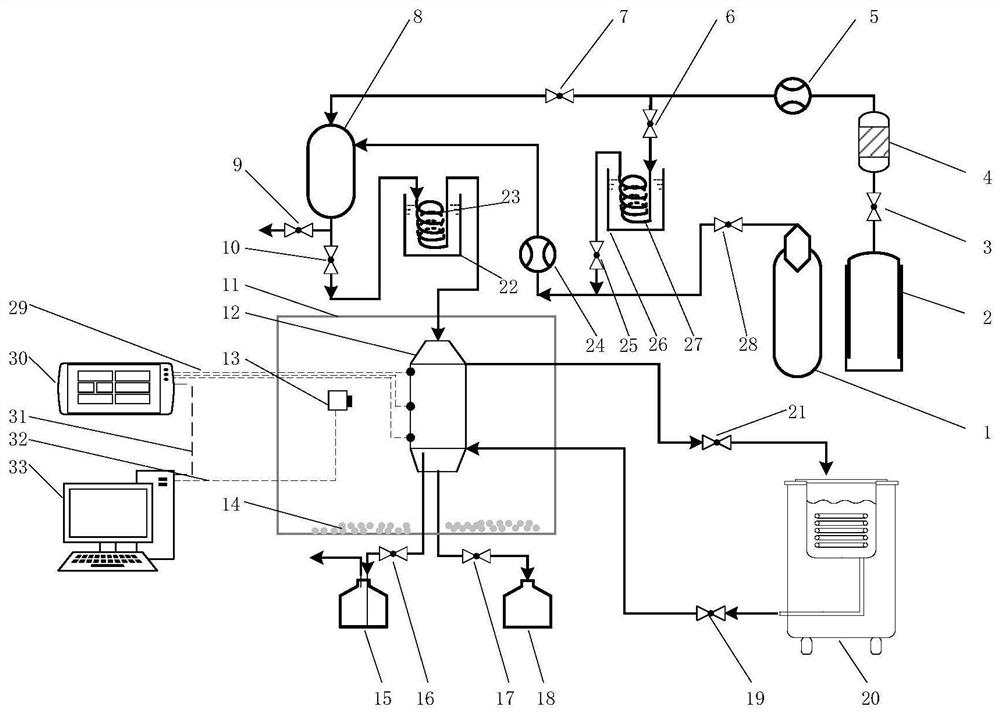

[0074] refer to figure 1 , this embodiment proposes a visual detection device for gas condensation heat transfer characteristics, the visual detection device includes:

[0075] Gas distribution unit, condensing unit, refrigeration unit and data acquisition unit;

[0076] The gas distribution unit is connected to the condensing unit, the refrigerating unit provides cooling capacity for the condensing unit, and the data acquisition unit collects temperature information and image information of the condensing unit.

[0077] refer to figure 1 , in this embodiment, the gas distribution unit includes:

[0078] Gas cylinder to be condensed 1, first rotameter 5, non-condensable gas cylinder 2, molecular sieve dehydration adsorber 4, second rotameter 24, gas mixing tank 8, heating system, constant temperature system and several first valves A ~G;

[0079] The non-condensable gas cylinder 2, the molecular sieve dehydration adsorber 4, the first rotameter 5 and the gas mixing tank 8 ...

Embodiment 2

[0108] This embodiment proposes a detection method using the visual detection device for gas condensation heat transfer characteristics described in Embodiment 1; the detection method includes the following steps:

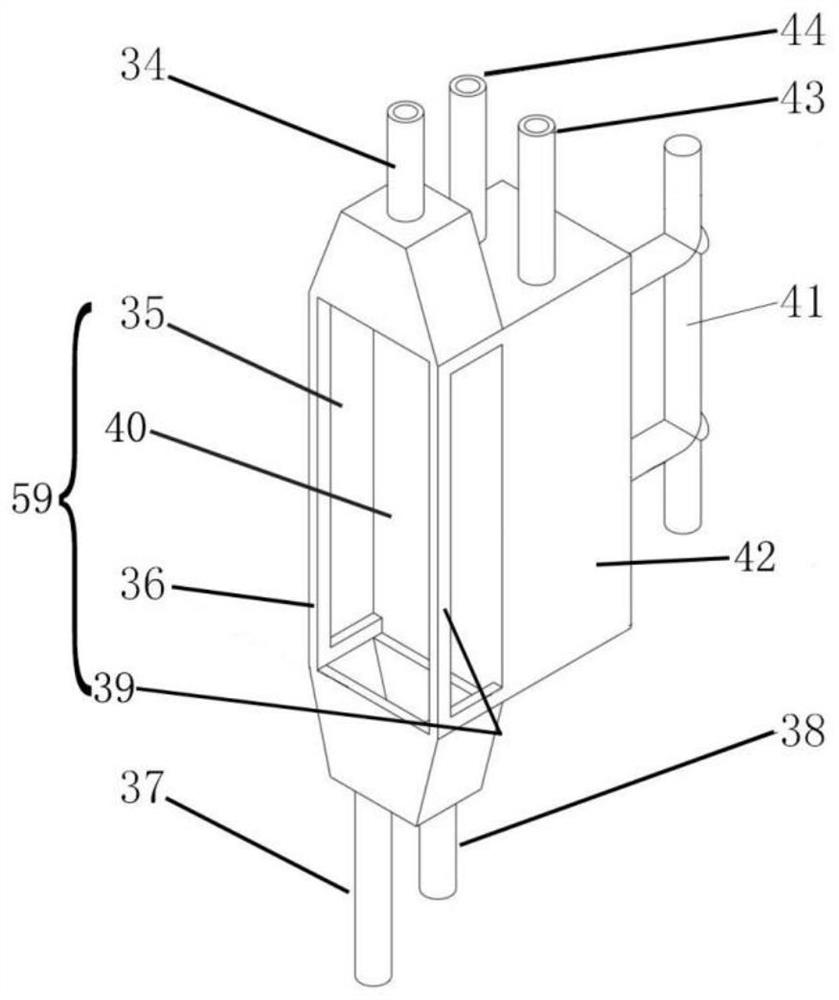

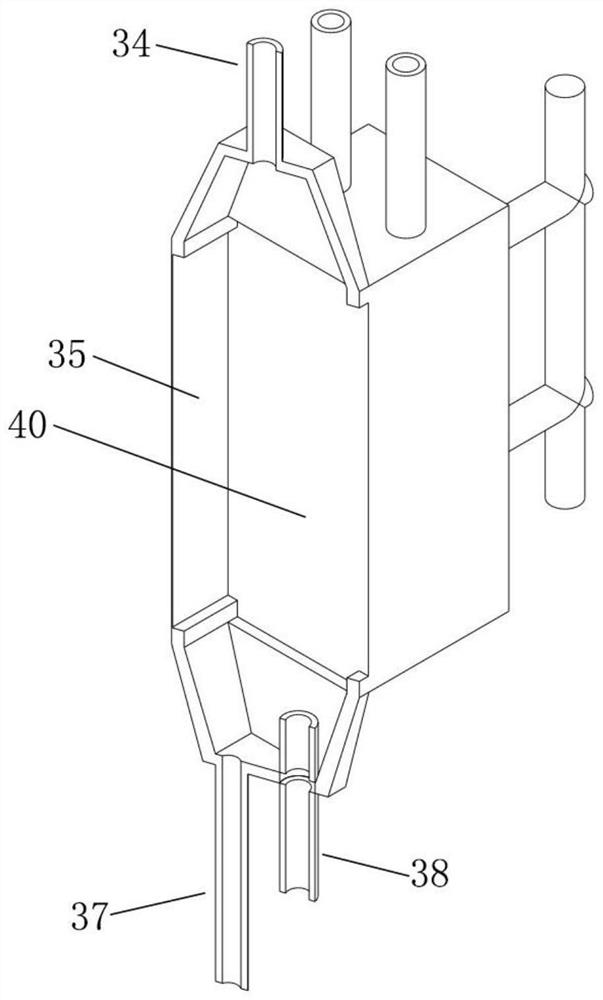

[0109] S1, install the thermocouple: install the thermocouple on the condensing device 12, the installation position includes: the gas inlet and outlet of the condensing device, the gas space in the airflow channel, and the condensing wall of the condensing device; the condensing wall of the condensing device is the same as the low-temperature water tank 42 the contact surface;

[0110] S2, refrigerating: using a refrigerator 20 to refrigerate the condensing device 12;

[0111] Specifically: open the refrigerator 20, the third valve A19 and the third valve A21, so that the brine circulates between the refrigerator 20 and the condensing device 12, and continuously transfers the cooling capacity to the condensing device 12;

[0112] S3, heating the second rotameter ...

Embodiment 3

[0127] According to the detection method of above-mentioned embodiment 2, this example uses high boiling point gas NO 2 As the gas to be condensed, the following detection tests are carried out with air as the non-condensable gas:

[0128] In this experiment, the air is only used to heat the second rotameter 24 and does not interact with the NO 2 The mixture enters the condensing unit 12.

[0129] The refrigerator was set at -10°C to -30°C to study NO 2 Condensation of mixed gas on 316 metal wall. Gas to be condensed NO 2 Cylinders are heated to 45°C to ensure NO 2 The gas flows out of the gas cylinder continuously, and the pipeline and gas mixing tank are heated to 60-70°C to prevent NO 2 Condensate before entering the condensing unit. Air heats the second rotameter 24, closes the non-condensable gas cylinder 2 after heating; then adjusts the second rotameter 24 to carry out 200ml / min of pure NO 2 Condensation of gas at -10°C, -15°C, -17°C, -19°C, -20°C, -21°C, -23°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com