Coating spray booth airflow velocity and pressure simulation method

A technology of airflow speed and simulation method, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as difficult control, consumption of manpower, material and financial resources, timely change of spray booth, etc., to achieve cost saving, accurate results, Effects for easy reference and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

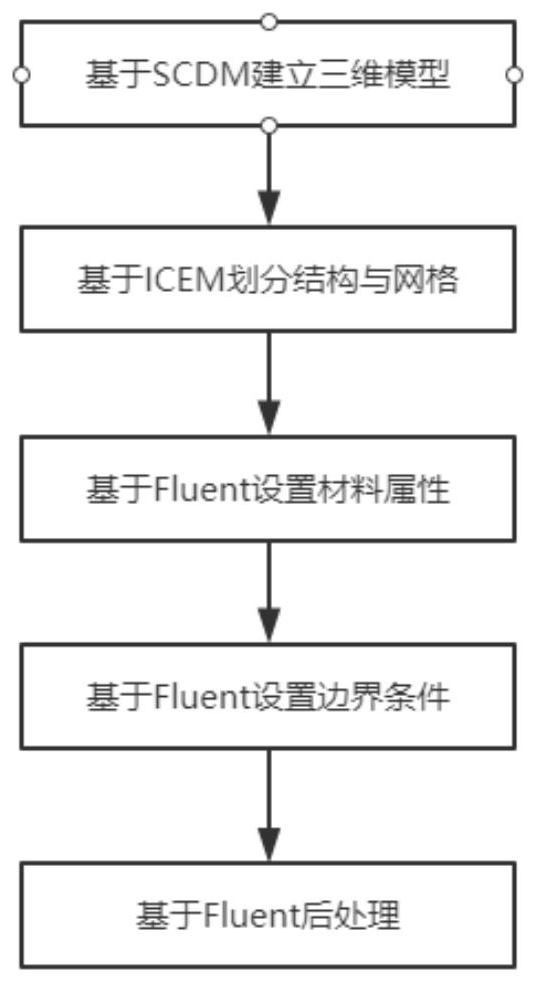

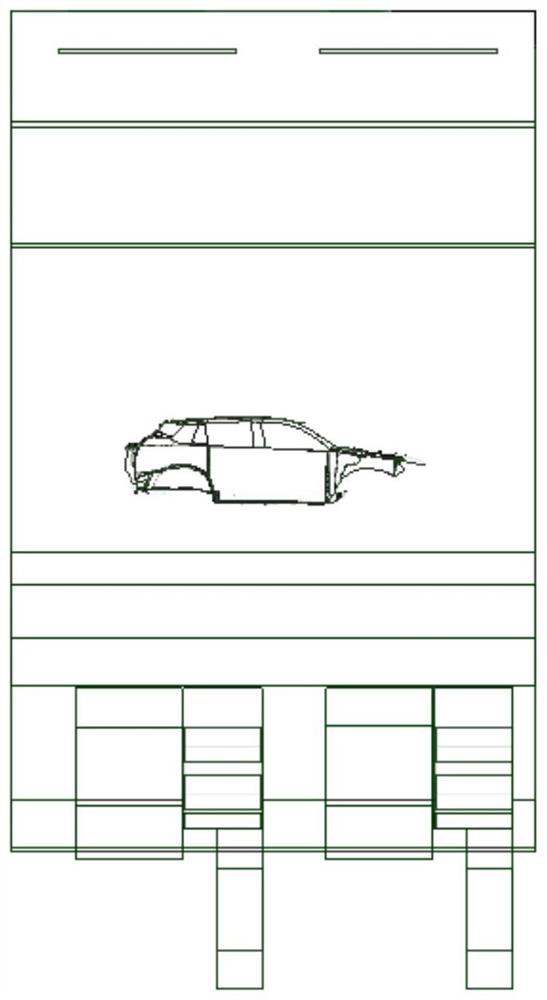

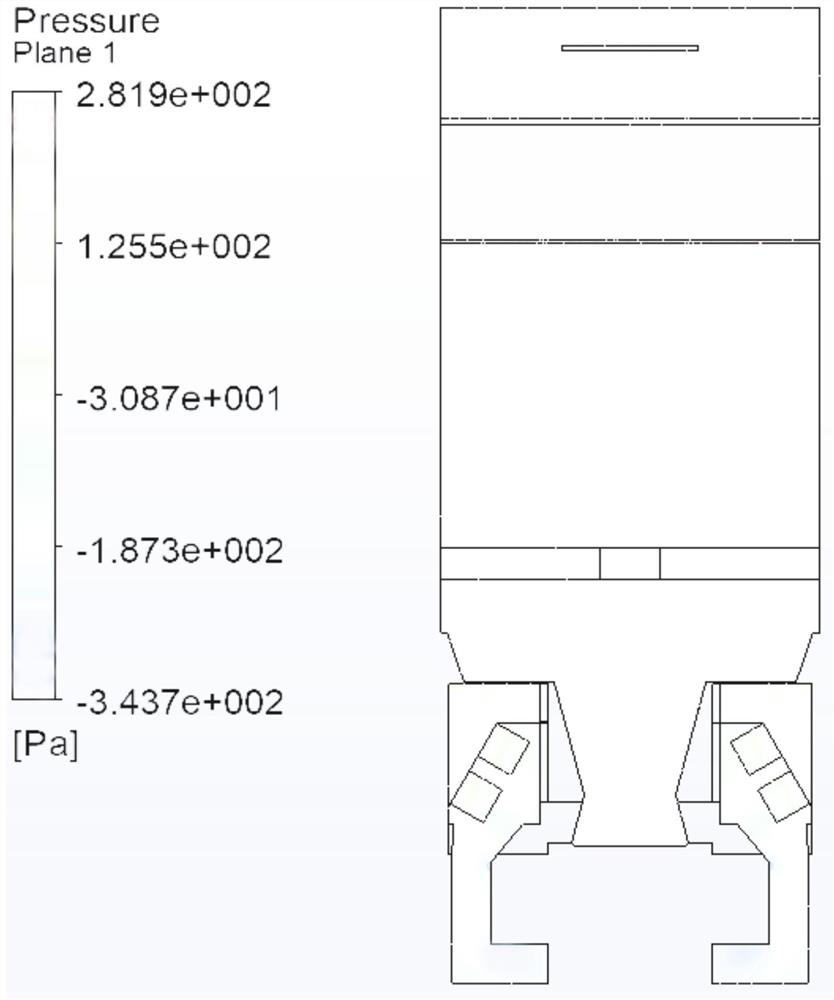

[0039] see Figure 1-4 , the present invention provides a technical solution: a method for simulating air velocity and pressure in a painting spray booth, which is operated based on SCDM, ICEM, and Fluent software, and includes the following steps:

[0040] Step 1, 3D modeling based on SCDM;

[0041] Step 2. Based on ICEM, divide the structure and grid of the 3D model generated by SCDM;

[0042] Step 3. Set the material properties of the grid structure generated by ICEM based on Fluent;

[0043] Step 4. Set the boundary conditions of the structure and grid based on Fluent;

[0044] Step 5. Perform subsequent processing based on Fluent.

[0045] Specifically, the modeling method in step 1 includes the following steps:

[0046] Step 101, importing the two-dimensional drawing of the spray booth;

[0047] Step 102, importing the two-dimensional drawings of the car body;

[0048] Step 103: Generate a 3D model based on SCDM software according to the imported paint spray booth ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap