Monitoring method and system for running process of heavy-load train based on interval type II

A technology for heavy-duty trains and running processes, applied in the directions of registration/indicating vehicle operation, reasoning methods, neural learning methods, etc. Non-linear and other issues, to achieve the effect of improving accuracy and realizing high-precision monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

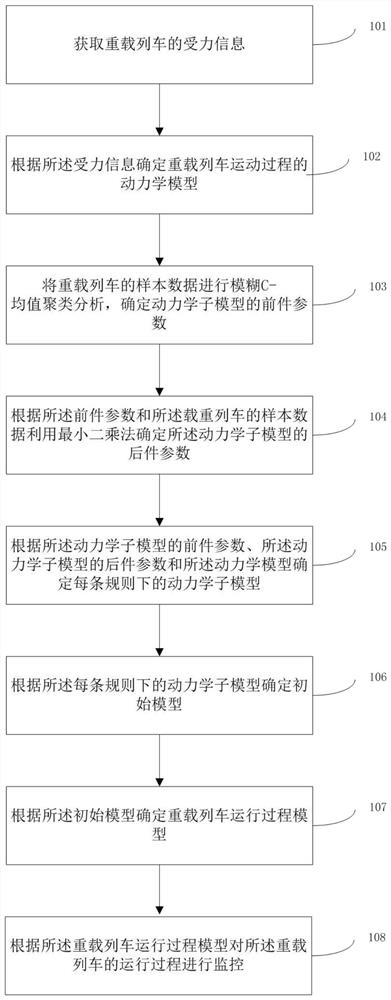

[0073] like figure 1 As shown, a kind of heavy-duty train running process monitoring method provided by the present embodiment includes:

[0074] Step 101: Obtain the force information of the heavy-haul train.

[0075] Step 102: Determine the dynamic model of the movement process of the heavy-haul train according to the force information.

[0076] Step 103: Perform fuzzy C-means cluster analysis on the sample data of the heavy-haul train to determine the antecedent parameters of the dynamic sub-model.

[0077] Step 104: According to the antecedent parameters and the sample data of the heavy-duty train, determine the consequent parameters of the dynamic sub-model by using the least square method.

[0078] Step 104 specifically includes:

[0079] The initial consequent parameter is determined by using the least square method according to the antecedent parameter and the sample data of the heavy-duty train.

[0080] A first model is determined based on the antecedent paramete...

Embodiment 2

[0102] This embodiment provides a specific implementation of a heavy-duty train operation process monitoring method, the steps are as follows:

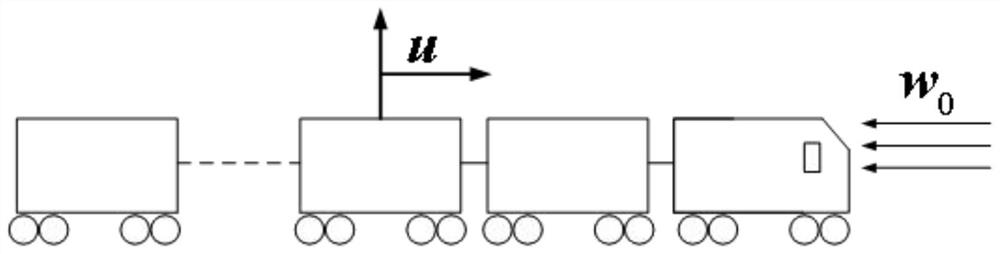

[0103] Analyze the stress situation during the operation of heavy-duty trains, such as figure 2 As shown, the dynamic model of its motion process can be expressed as:

[0104]

[0105] In the formula, y is the running speed of the heavy-duty train, ε is the acceleration coefficient, u is the unit control force (traction force / braking force), ω 0 =A+By+Cy 2 , ω 0 is the unit of basic resistance, A, B, and C are the resistance coefficients, and the differential equation of formula (1) is expressed as:

[0106] y(k)=f{y(k-1), u(k-1)} (2)

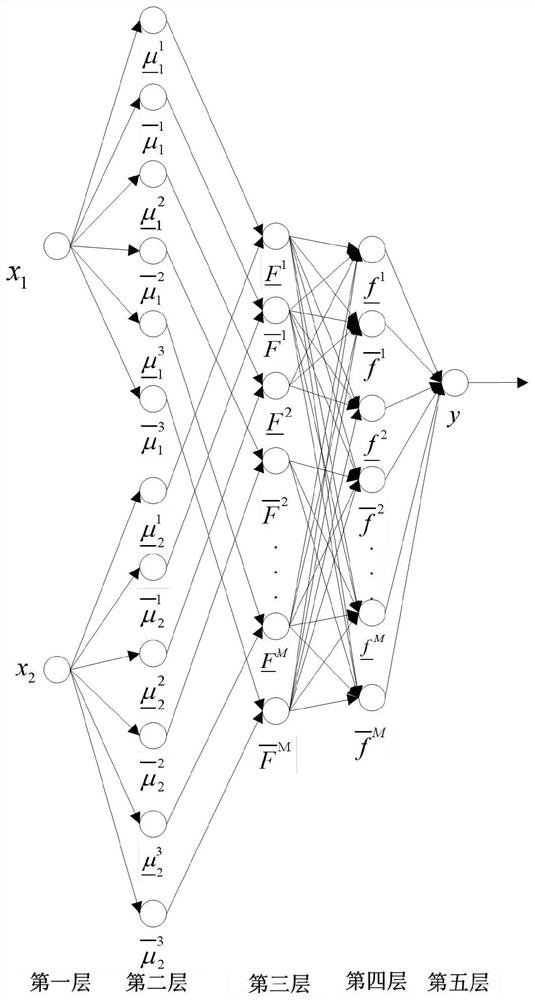

[0107] According to the operation process of the heavy-duty train, fuzzy reasoning rules are used to model the model, and the linear structure of the sub-model is determined based on the mathematical equation description of the force of the heavy-duty train operation process. When the rule is d...

Embodiment 3

[0155] like Figure 8 As shown, the present embodiment also provides a heavy-duty train operation process monitoring system, including:

[0156] The force information acquisition module 801 is used to acquire the force information of the heavy-haul train.

[0157] A dynamic model determining module 802, configured to determine a dynamic model of the heavy-haul train's motion process according to the force information.

[0158] The antecedent parameter determination module 803 of the dynamic sub-model is used to perform fuzzy C-means cluster analysis on the sample data of the heavy-haul train to determine the antecedent parameters of the dynamic sub-model.

[0159] The subsequent parameter determination module 804 of the dynamic sub-model is configured to determine the subsequent parameter of the dynamic sub-model by using the least square method according to the preceding parameter and the sample data of the heavy-duty train.

[0160] A dynamic submodel determining module 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com