Optimization method of shot blasting-acid pickling combined type descaling process

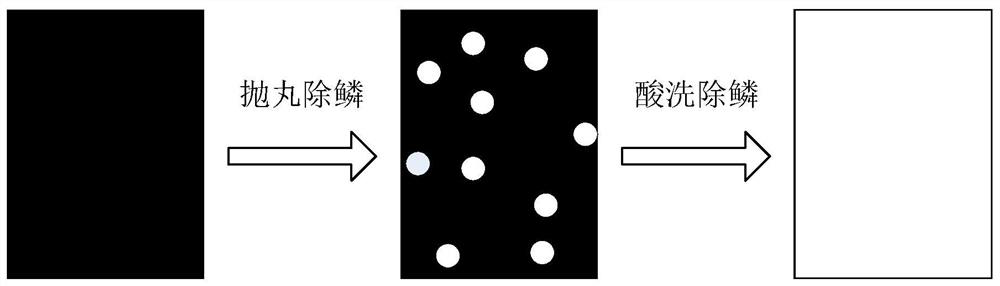

A process optimization and composite technology, applied in the field of iron and steel production, can solve the problems of ineffective acid reduction, immature process, high cost, etc., and achieve the effects of improving energy efficiency, broad market application prospects, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the technical problems, technical solutions and advantages to solve the present invention more clearly, and will be described in detail below with reference to the accompanying drawings and specific examples.

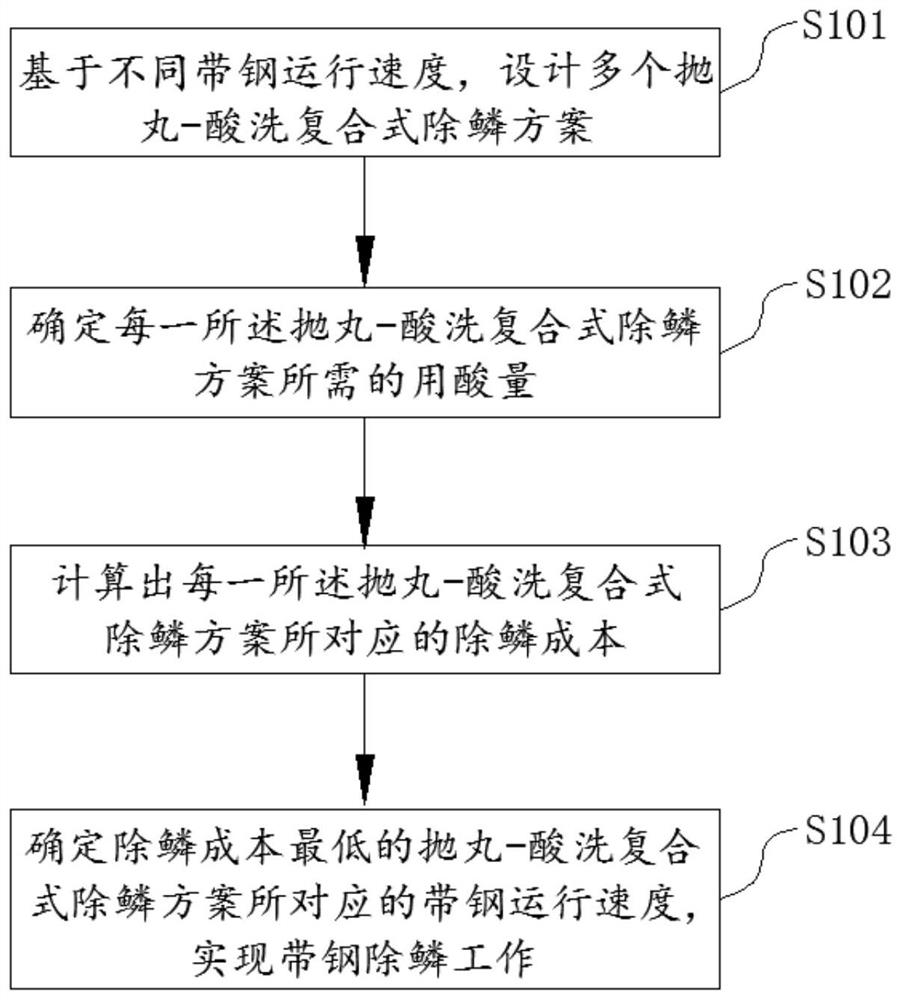

[0065] Such as figure 1 As shown, embodiments of the present invention provide a method of throwing-pickled composite scales process optimization process, including:

[0066] S101, designed multiple shot pills-acid washing complex scales regimen; where each of the stripping-pickled composite scales regimen is different from each other;

[0067] It should be noted that in the present embodiment, the above S101 specifically:

[0068] 1. Determination of strip steel benchmark operation speed ν c ;

[0069] 2. According to the formula

[0070] ν i = I × k -1 × ν c

[0071] Each shot-pickled composite scorpion scheme is calculated to obtain each shot-pickled composite scorching scheme.

[0072] among them,

[0073] K indicates the number of throwing-pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com