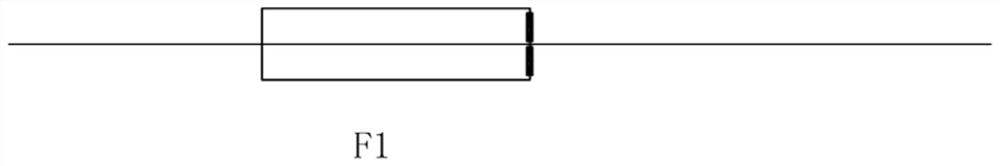

Temperature fuse assembly

A technology of thermal fuses and components, applied in electrical components, circuits, emergency protection devices, etc., can solve problems such as excessive AC or DC current, inability to cut off and protect circuits, etc., to achieve the effect of improving the safe cut-off voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

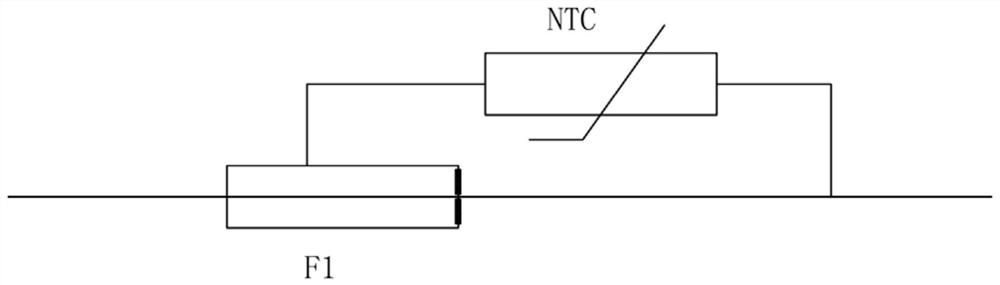

[0023] Example 1, such as figure 2 As shown, more than one suitable negative temperature coefficient ceramic NTC thermistor is connected in parallel at both ends of the temperature fuse F1. When the temperature fuse F1 is first disconnected, the current is quickly transferred to the negative temperature coefficient ceramic NTC thermistor. The current of the fuse F1 drops rapidly between electric shocks, so as to give the temperature fuse F1 enough disconnection time to ensure safe and effective cut-off of the circuit.

[0024] In this embodiment, the negative temperature coefficient ceramic NTC thermistor is connected across the two ends of the insulating sleeve of the temperature fuse F1, such as figure 2 shown. The negative temperature coefficient ceramic NTC thermistor has a resistance value of 1-50 ohms at room temperature; under normal operating temperature conditions, the temperature fuse F1 works normally, and the current mainly passes through the temperature fuse, a...

Embodiment 2

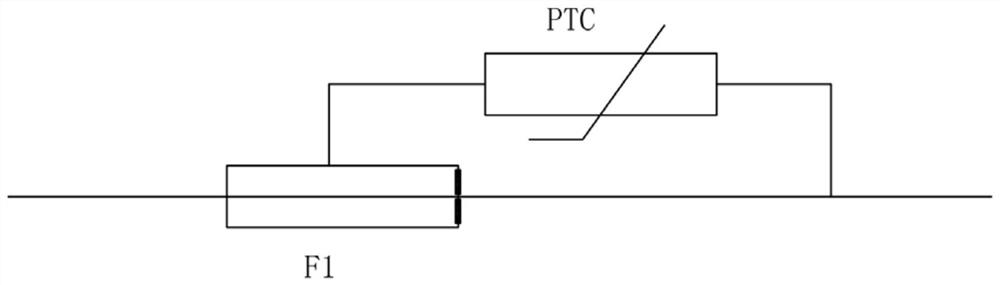

[0025] Example 2 as image 3 As shown, in this embodiment, a positive temperature coefficient PTC ceramic thermistor is connected in parallel at both ends of the temperature fuse F1. When the temperature fuse F1 starts to disconnect, the current is quickly transferred to the positive temperature coefficient PTC ceramic thermistor. , The current between the thermal fuse F1 and the electric shock drops rapidly, so as to give the thermal fuse enough disconnection time to ensure safe and effective cut-off of the circuit.

[0026] In this embodiment, the positive temperature coefficient ceramic PTC thermistor is connected across the two ends of the insulating sleeve of the temperature fuse F1, such as image 3 shown. The positive temperature coefficient ceramic PTC thermistor has a resistance value of 1-50 ohms at room temperature; under normal operating temperature conditions, the temperature fuse F1 works normally, and the current mainly passes through the temperature fuse F1 an...

Embodiment 3

[0027] Example 3 as Figure 4 As shown, an ultra-fine metal wire resistor R is connected in parallel at both ends of the temperature fuse, and the material of the ultra-fine metal wire is silver, copper, tungsten, palladium, silver-tungsten alloy or copper-tungsten alloy. When the thermal fuse F1 starts to disconnect, the current is quickly transferred to the ultra-fine wire resistor R, and the current between the thermal fuse F1 and the electric shock drops rapidly, thus giving the thermal fuse F1 enough disconnection time to ensure safety Effectively cuts the circuit.

[0028] In the embodiment provided by the present invention, such as figure 2 As shown, the ultra-fine wire resistance R is connected across the two ends of the insulation sleeve of the temperature fuse F1. The diameter of the metal wire in the ultra-fine wire resistance R is 0.01-0.55mm; the resistance is 1 milliohm-2000 milliohms, which can be cut off safely 36-450V / 10-40A AC and DC circuits.

[0029] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com