Conductive rod for vacuum interrupter, processing method thereof, and vacuum interrupter

A technology of vacuum interrupter and processing method, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems such as deformation, stagnation and bending of moving conductive rods that cannot be solved, and achieve safe cutting, increase service life, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

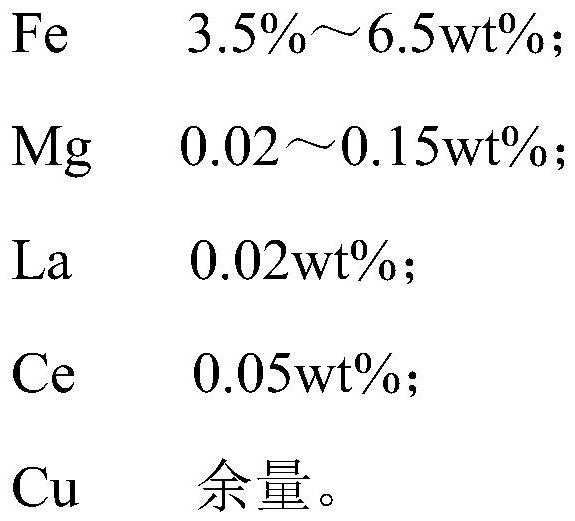

[0047] The formula is composed of the following components: Fe 5wt%, Mg 0.02wt%, La 0.02wt%, Ce 0.05wt%, and the balance is Cu.

[0048] Cleaning of the raw materials: Pickling the cathode copper and industrial pure iron, washing them with water, and drying them for later use. The cathode copper pickling solution adopts 30% volume concentration sulfuric acid, and the industrial pure iron pickling solution adopts 25% volume concentration hydrochloric acid.

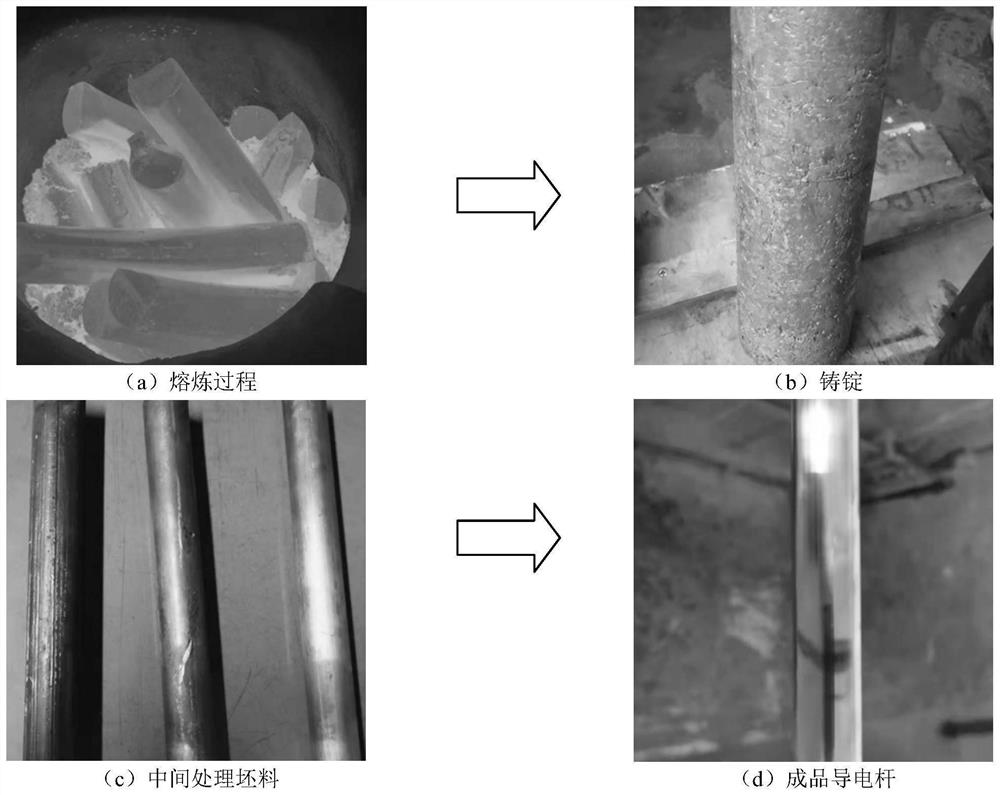

[0049] The vacuum smelting: heating the crucible under low power, vacuuming and degassing, the vacuum degree reaches 1.0×10 -2 Stop pumping after Pa, fill Ar gas to 0.05MPa, and start smelting Cu; wait for Cu to completely melt and let it stand for 5 minutes, increase the power to smelt Fe until it is completely melted, then reduce the power and let it stand for 10 minutes, put CuMg50, CuLa40, CuCe40 in the middle Add the alloy into the melt; after the intermediate alloy is completely melted, increase the power to refine a...

Embodiment 2

[0058] The invention provides a processing method for a conductive rod used in a vacuum interrupter, and the processing method is as follows:

[0059] (1) Conductive rod composition: Fe 3.5%wt%, Mg 0.02wt%, La 0.02wt%, Ce 0.05wt%, and the balance is Cu.

[0060] (2) Cleaning: the cathode copper and industrial pure iron are pickled, washed with water and dried for later use. The cathode copper pickling solution adopts 30% volume concentration sulfuric acid, and the industrial pure iron pickling solution adopts 25% volume concentration hydrochloric acid.

[0061] (3) Melting: Heating the crucible under low power, vacuuming and degassing, the vacuum degree reaches 1.0×10 -2 Stop pumping after Pa, fill Ar gas to 0.05MPa, and start smelting Cu; wait for Cu to completely melt and let it stand for 5 minutes, increase the power to smelt Fe until it is completely melted, then reduce the power and let it stand for 10 minutes, put CuMg50, CuLa40, CuCe40 in the middle Add the alloy into...

Embodiment 3

[0068] The invention provides a processing method for a conductive rod used in a vacuum interrupter, and the processing method is as follows:

[0069] (1) Conductive rod composition: Fe 6.5wt%, Mg 0.15wt%, La 0.02wt%, Ce 0.05wt%, and the balance is Cu.

[0070] (2) Cleaning: the cathode copper and industrial pure iron are pickled, washed with water and dried for later use. The cathode copper pickling solution adopts 30% volume concentration sulfuric acid, and the industrial pure iron pickling solution adopts 25% volume concentration hydrochloric acid.

[0071] (3) Melting: Heating the crucible under low power, vacuuming and degassing, the vacuum degree reaches 1.0×10 -2 Stop pumping after Pa, fill Ar gas to 0.05MPa, and start smelting Cu; wait for Cu to completely melt and let it stand for 5 minutes, increase the power to smelt Fe until it is completely melted, then reduce the power and let it stand for 10 minutes, put CuMg50, CuLa40, CuCe40 in the middle Add the alloy into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com