Feed feeding device for aquaculture

A technology of aquaculture and feeding device, which is applied in the direction of mixer with rotating stirring device, application, fish farming, etc. It can solve the problems of feed agglomeration, cost waste, slow manual feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

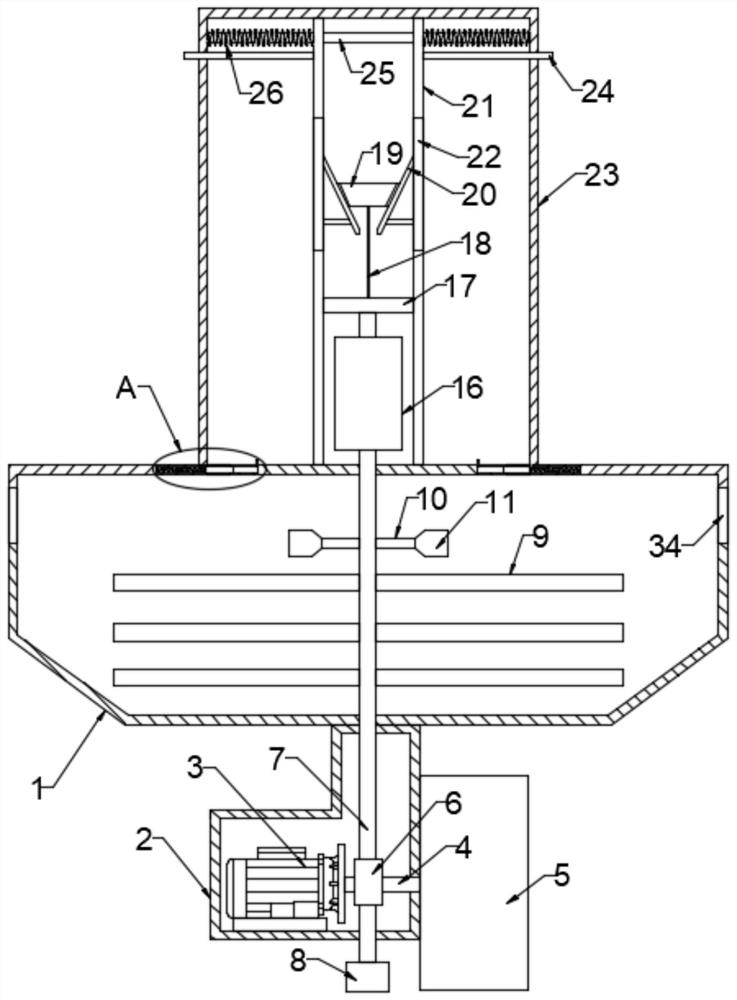

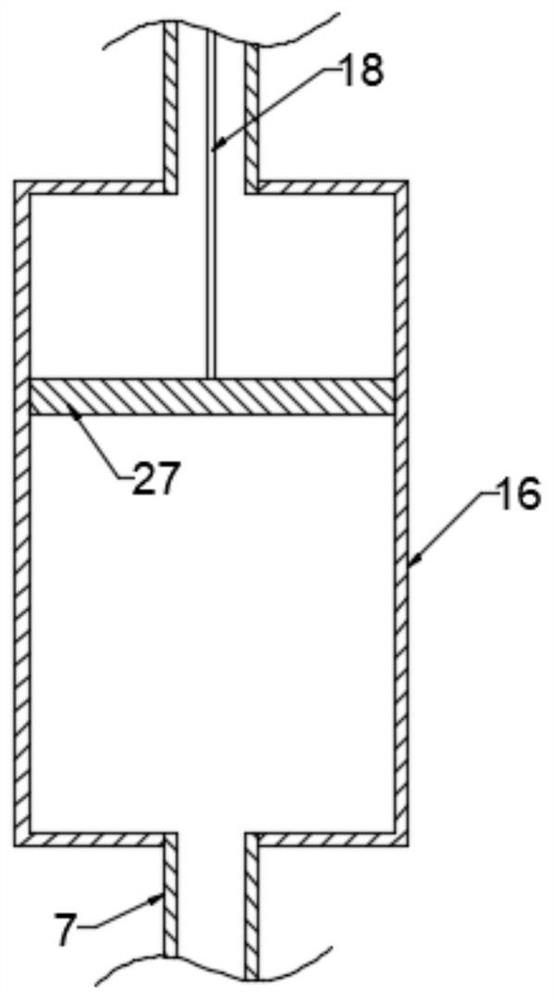

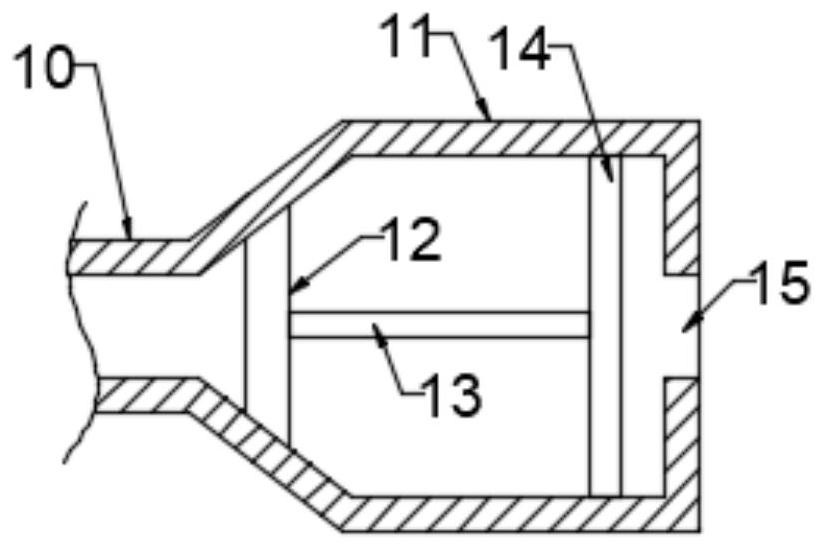

[0027] see Figure 1-5 , a feed feeding device for aquaculture, comprising a floating box 1, a motor box 2 is fixedly connected to the bottom of the floating box 1, a blade drive mechanism 5 is connected to one side of the motor box 2, and the blade drive mechanism 5 is connected to a The drive shaft 4 that drives its action, the drive shaft 4 extends into the motor box 2 and is fixedly connected with the drive motor 3 that drives its rotation, the rod body of the drive shaft 4 located in the motor box 2 is a worm and is meshed with a turbine 6, The axis of the turbine 6 runs through and is fixedly connected with a hollow water pipe 7. The lower end of the hollow water pipe 7 extends to the bottom of the motor box 2 and is fixedly connected with a filter cover 8. The upper end of the hollow water pipe 7 extends to the top of the floating box 1 and is fixedly connected with a symmetrical eccentric wheel. 17. The hollow water pipe 7 is rotationally connected with the floating bo...

Embodiment 2

[0031] This embodiment is expanded on the basis of Embodiment 1. The discharge mechanism includes a material blocking slide 29 that is slidably connected to the top plate of the floating box 1 and blocks the discharge groove 28. The chute 30 matched with the material slide plate 29, the bottom wall of the chute 30 is elastically connected with the material retaining slide plate 29 through the second elastic member 31, the second elastic member 31 is preferably a spring, and the material retaining slide plate 29 is away from the second elastic member One end of 31 is fixedly connected with a tapered slide bar 32 which is slidably connected with the top plate of the floating box 1, and the tapered slide bar 32 is fixedly connected with a driving slide bar which is slidably connected with the top plate of the floating box 1 and extends to the top plate of the floating box 1 33. When the extrusion crushing plate 21 moves, the extrusion crushing plate 21 squeezes the driving slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com