Crusher for hydraulic engineering construction and crushing method thereof

A technology for water conservancy projects and crushers, which is applied in grain processing and other directions, and can solve problems such as inability to crush sediment by electric shock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

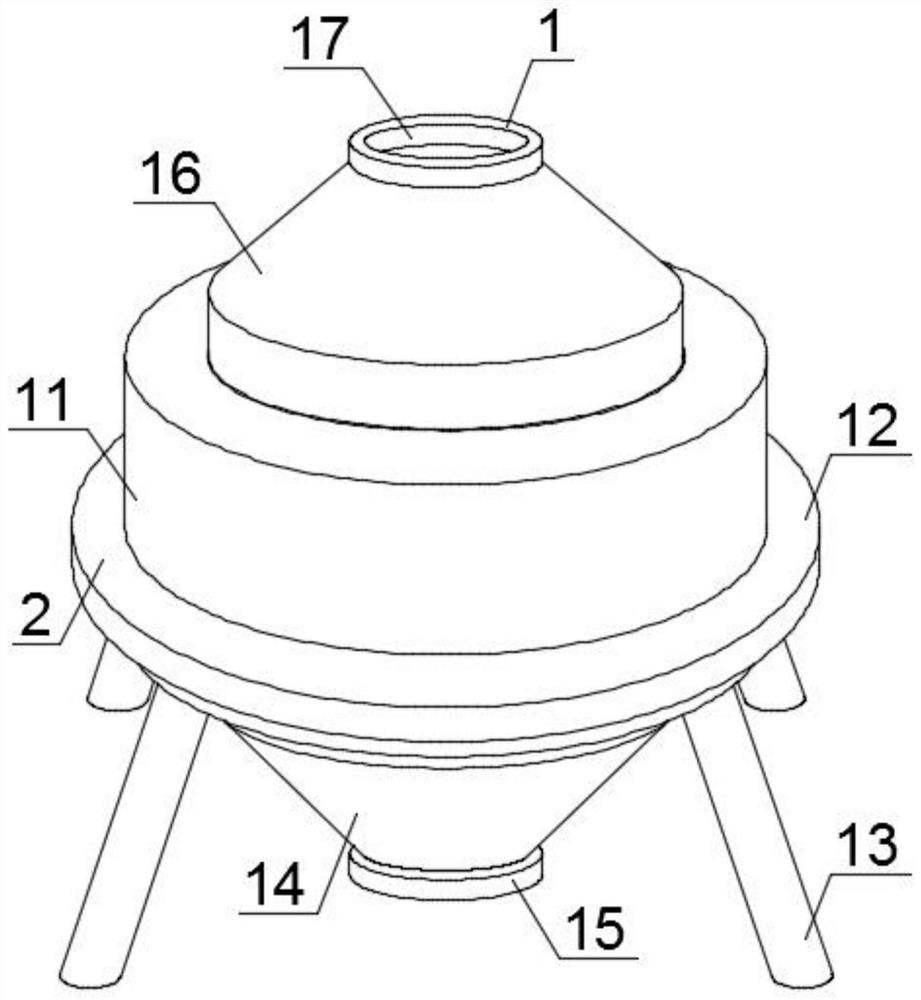

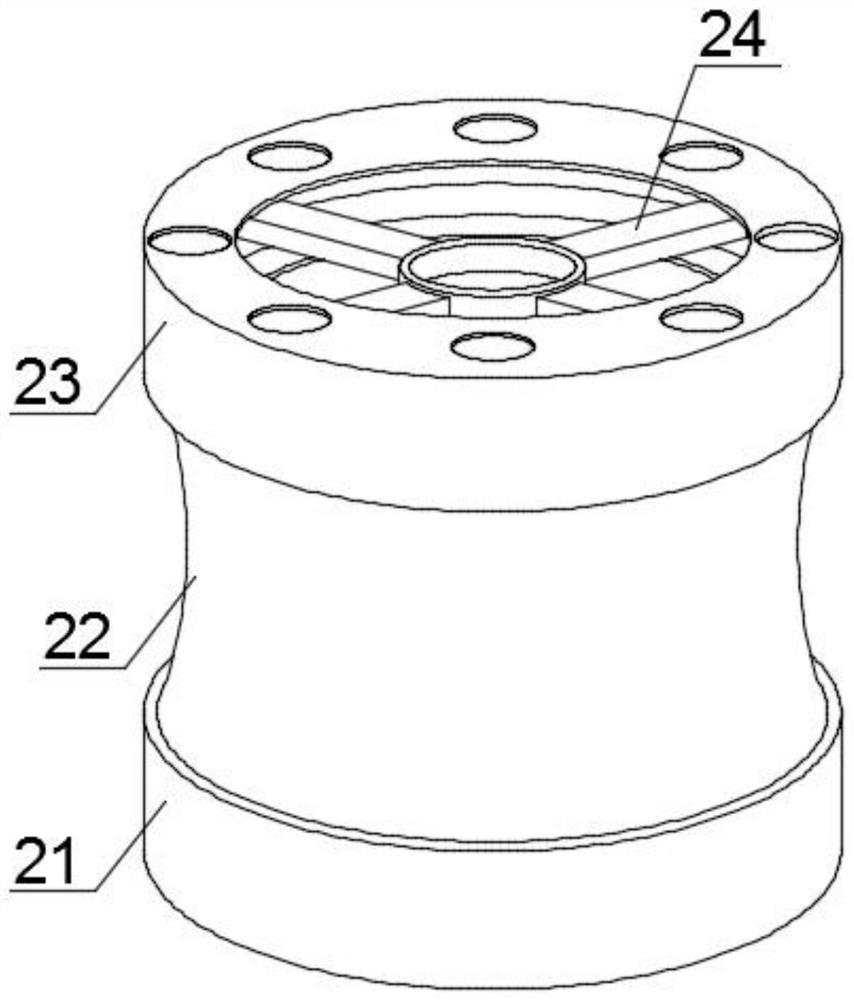

[0033] Such as figure 1 , 2As shown in and 4, a crusher for water conservancy construction includes an outer frame tube 1 and a crushing mechanism 2, the inner cavity of the outer frame tube 1 is equipped with a crushing mechanism 2, and the outer frame tube 1 includes a cylinder body 11 1. Install ring buckle 12, support frame 13, install lower shell 14, lower material shell 15, assemble upper shell 16 and feed hole 17, the outer ring of cylindrical body 11 is equipped with installation ring buckle 12, and the lower end ring of installation ring buckle 12 A support frame 13 is provided, a lower shell 14 is installed on the lower end of the cylindrical body 11, a lower shell 15 is provided on the bottom end of the lower shell 14, an upper shell 16 is installed on the upper end of the cylindrical body 11, and the top end of the upper shell 16 is assembled. A feeding hole 17 is provided, and a crushing mechanism 2 is installed in the inner cavity of the cylinder body 11. The cr...

Embodiment 2

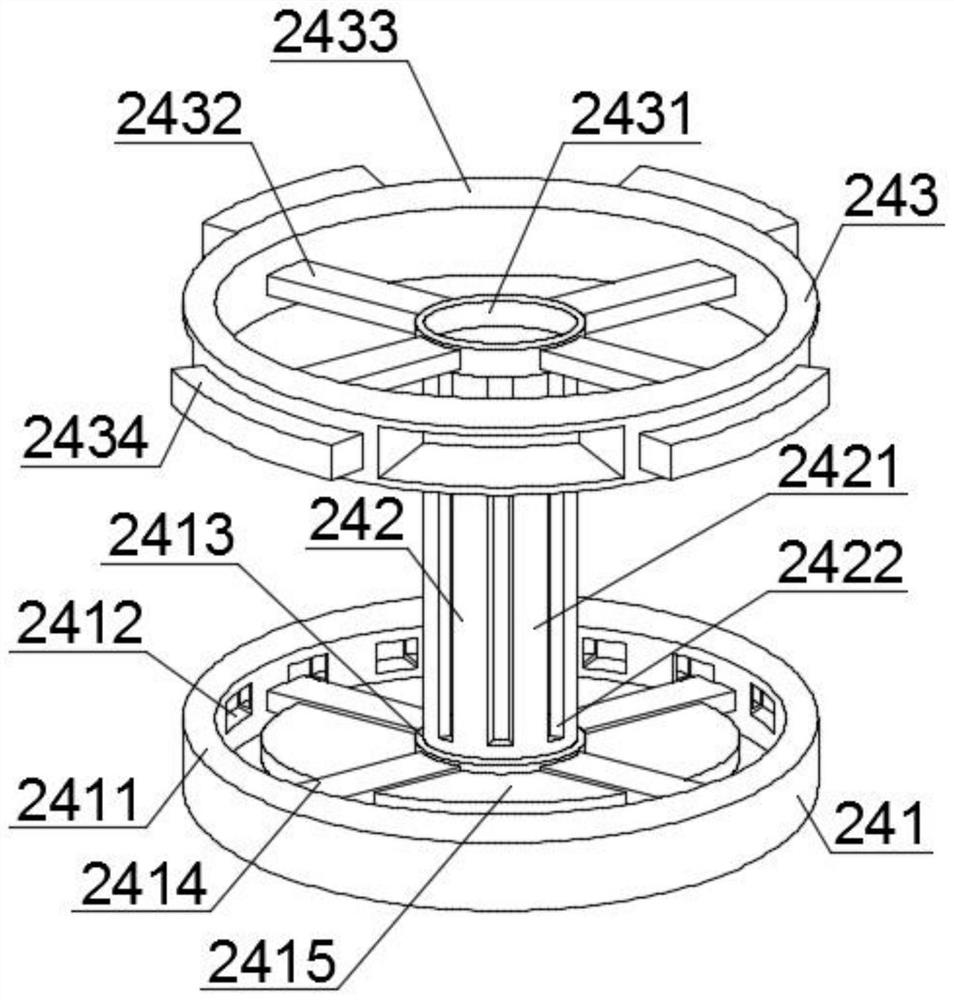

[0035] Such as image 3 As shown, a crusher for water conservancy construction, the rotating mechanism 243 includes an inner ring 2431, an outer ring rod 2432, an outer ring 2433 and a contact piece 2434, and the outer ring of the inner ring 2431 is provided with an outer ring rod 2432, the other end of the outer ring rod 2432 is equipped with an outer open ring 2433, the outer ring of the outer open ring 2433 is provided with a contact piece 2434, the outer end of the contact piece 2434 is attached to the inner cavity wall of the upper mounting shell 23, and the contact piece 2434 It is a component made of alloy material. The installation mechanism 241 includes an assembly ring 2411, an inner through cavity 2412, an inner mounting block 2413, an outer extension rod 2414 and an inner connecting plate 2415. The inner cavity of the assembly ring 2411 is provided with an inner through cavity 2412. The inner cavity of the assembly ring 2411 is equipped with an inner mounting block...

Embodiment 3

[0037] Such as Figure 5 As shown, a crusher for water conservancy project construction, the rolling mechanism 165 includes a driving motor 1651, an adjusting spring block 1652, a mounting frame 1653 and a rolling assembly rod 1654, and the upper end of the driving motor 1651 is equipped with an adjusting spring block 1652, A mounting frame 1653 is installed on the top of the adjustment spring block 1652, and a rolling assembly rod 1654 is arranged on the side end of the mounting frame 1653, and the sediment to be processed is placed into the inner cavity of the device through the feeding hole 17, and placed in the inner cavity. The inner cavity of the embedded cavity 164 is driven by the driving motor 1651 to drive and adjust the elastic block 1652 to repeatedly lift and lower the mounting frame 1653. The power generated by the lifting makes the rolling assembly rod 1654 beat the sand to achieve the effect of rolling. The moisture in the silt is separated and removed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com